Setting up Compax3

C3I12T11

192-120113 N08 C3I12T11 - December 2010

efficient aid available to increase the signal quality. Increase in signal quality in the

observer means that the noise components decrease, and the dynamics improve

as the observed speed is feedforward-controlled undelayed by the current and is

not just calculated delayed from the position signal using simple differentiation.

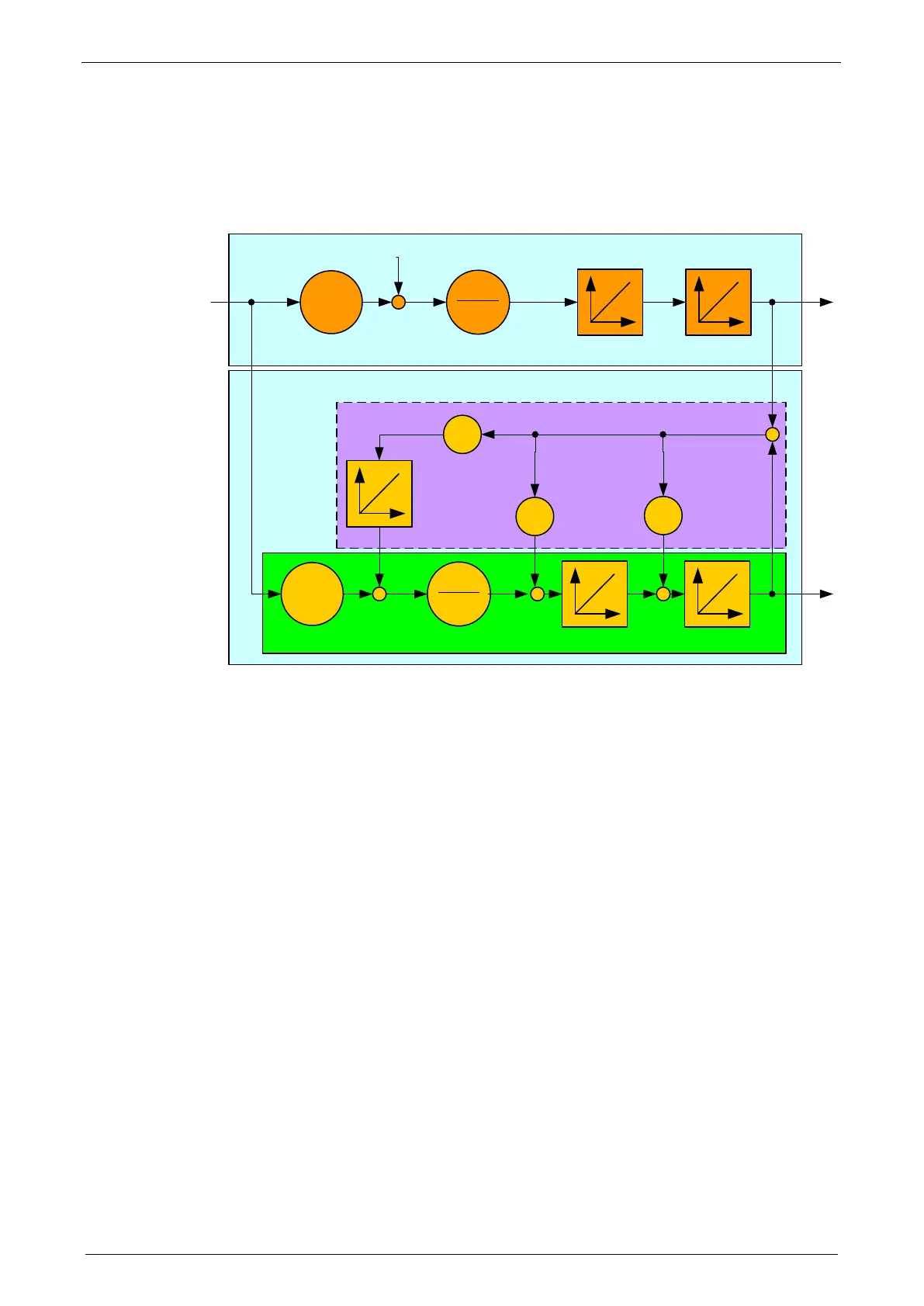

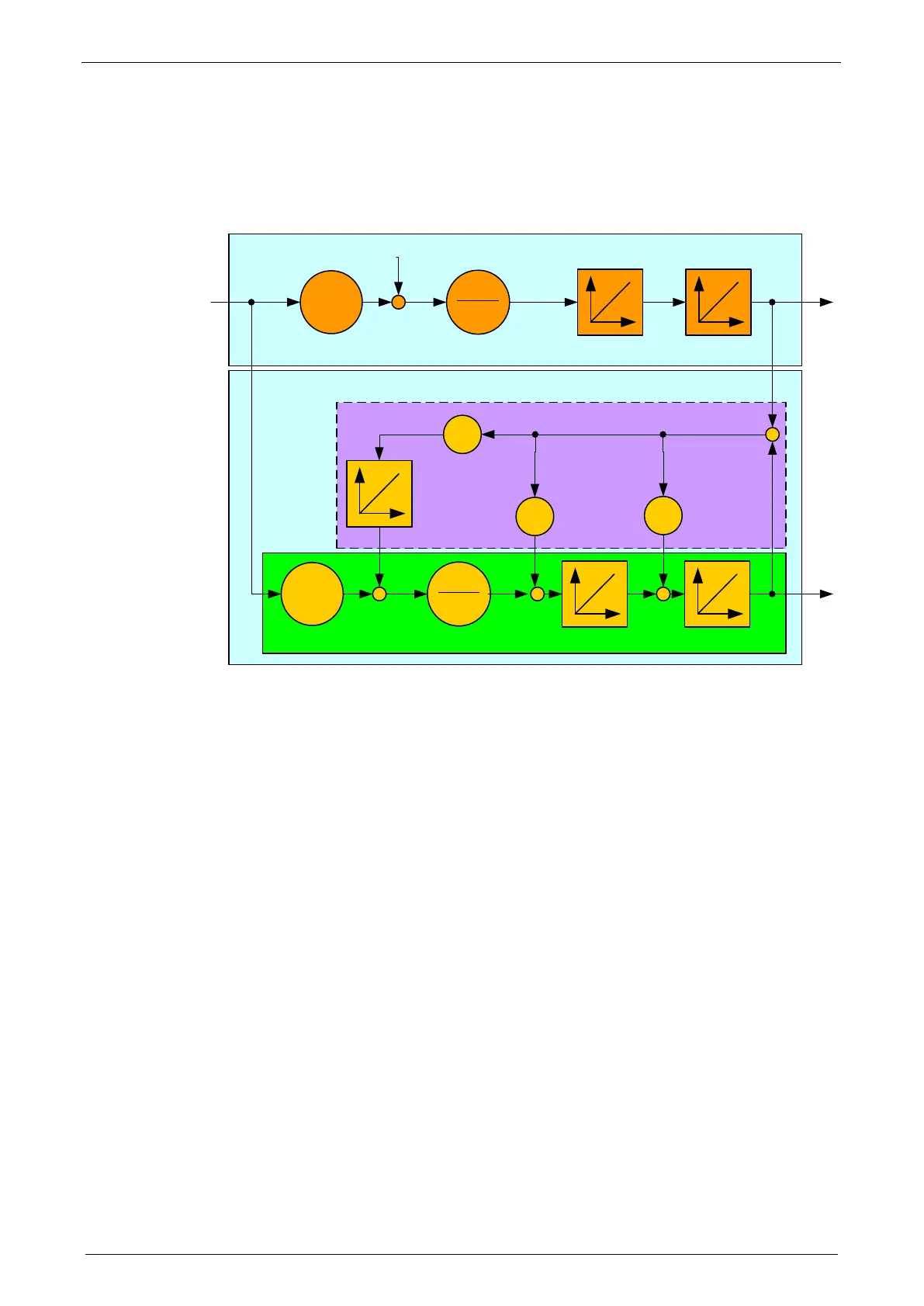

Signal flow chart Luenberg observer

-

Regelstrecke / controlled system

Beobachter / observer

I(t)

Nachführregler / tracking controller

Modell / model

I(t): Torque-forming motor current

Kt: Torque constant

ML(t): External disturbance torque

Jtotal: Total mass moment of inertia (motor + load)

a(t): Acceleration

n(t): Velocity

x(t): Position

Index b: Observed signal quantities

h0…h2: Controller coefficients of the tracking controller

The figure shows that an additional I element is connected for interference

compensation to correct external disturbance forces in the observer. Therefore the

speed and the acceleration observed are statically precise. The same applies to

the output of the integrator in the tracking controller which is a statically precise

determination of an external interference torque ML. For this reason, the I

component is not required in the speed controller for some applications, and the

entire control can be set up as a state cascade control. This increases the

bandwidth of the speed and position controlled member by factor 2. As a

consequence, the interference stiffness of the drive and the following error

behavior improve.

Here the quantization of the speed signal is proportional to the sampling time TAR,

hence there is no longer any conflict between the requirements for minimum

sampling time and minimum quantization noise. For the integral velocity

acquisition, the motor current variable, which is proportional to the acceleration,

can be used. This approach is particularly advantageous in direct drive

engineering; due to the absence of a mechanical drive train, there is a very good

Loading...

Loading...