Parker EME

Setting up Compax3

192-120113 N08 C3I12T11 - December 2010

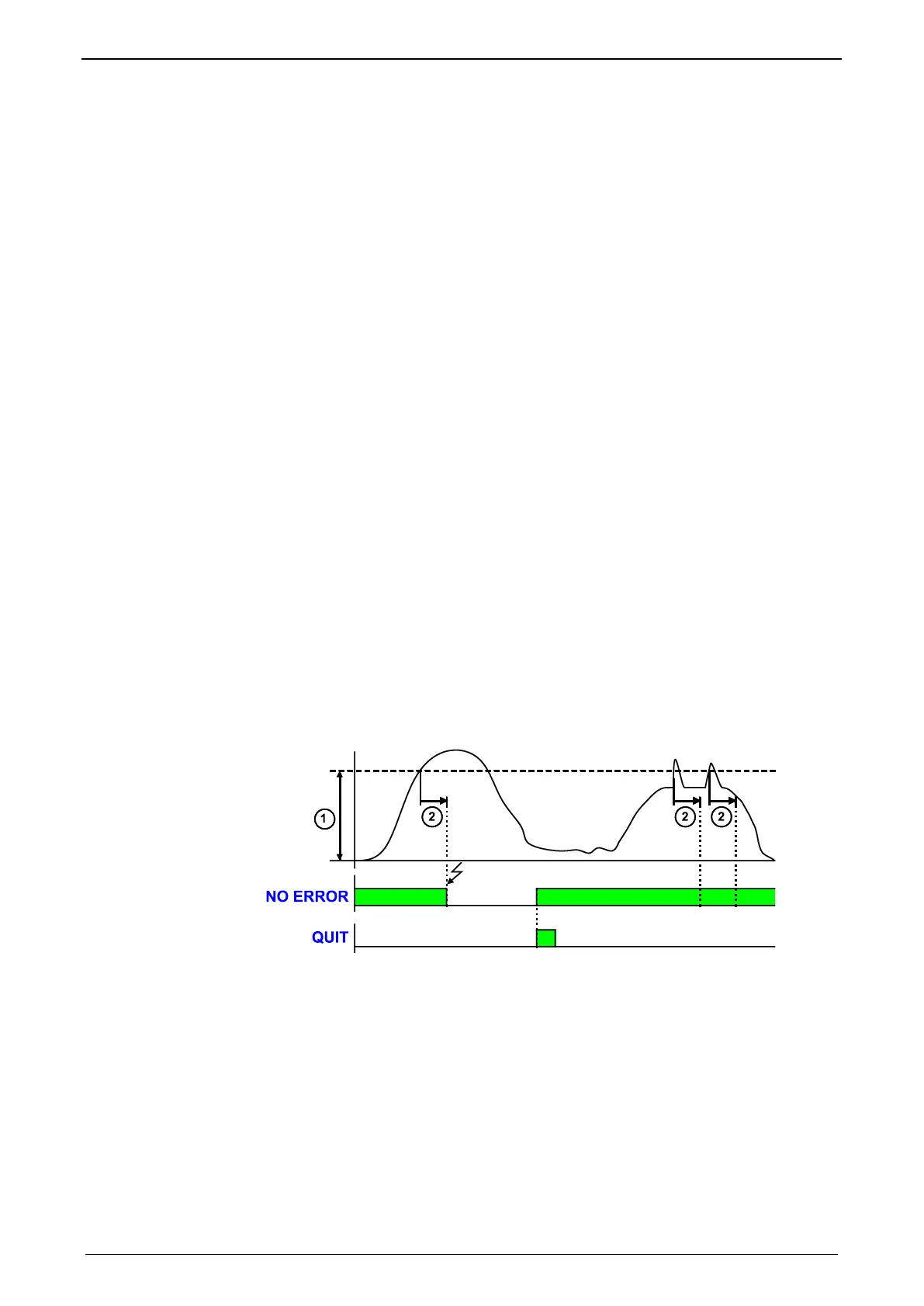

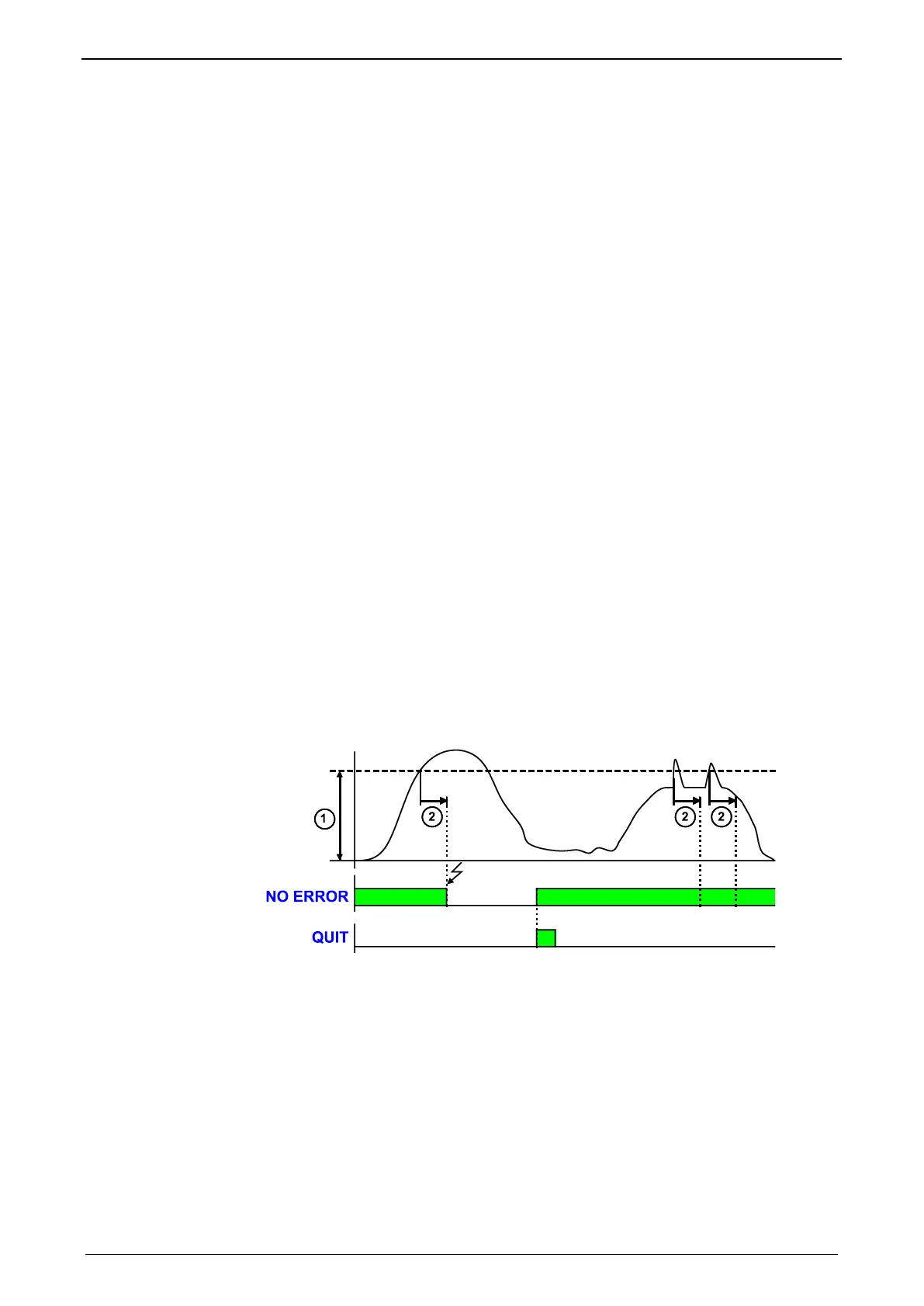

4.1.9.3 Following error limit

The error reaction upon a following error can be set:

Possible settings for the error reaction are:

No response

Downramp / stop

Downramp / stromlos schalten (standard settings)

The following error is a dynamic error.

The dynamic difference between the setpoint position and the actual position

during a positioning is called the following error. Do not confuse this with the static

difference which is always 0; the target position is always reached exactly.

The change of position over time can be specified exactly using the parameters

jerk, acceleration and speed. The integrated Setpoint value generator calculates

the course of the target position. Because of the delay in the feedback loop, the

actual position does not follow the target position exactly. This difference is referred

to as the following error.

When working with a number of servo drives (for example Master controller and

slave controller), following errors lead to problems due to the dynamic position

differences, and a large following error can lead to positioning overshoot.

If the following error exceeds the specified following error limit, the “following error

time” then expires. If the following error is even greater than the following error limit

at the end of the following error time, an error is reported.

If the following error falls short of the following error limit, a new following error time

is then started.

The following error can be minimized with the help of the extended (advanced)

control parameters, in particular with the feed forward parameters.

1: Following error limit

2: Following Error Time

NO ERROR: O0: no error

ACKN: I0: Quit (on positive edge)

4.1.9.4 Maximum operating speed

The speed limitation is deduced from the maximum operating speed. In order to

ensure control margins, the speed is limited to a higher value.

The speed setpoint value is actively limited to 1.1 times the given value.

If the speed actual value exceeds the preset maximum speed by 21% (=”switching

off limit speed”), error 0x7310 is triggered.

caused by a

Minimizing the

following error

Loading...

Loading...