Parker EME

Setting up Compax3

192-120113 N08 C3I12T11 - December 2010

4.1.11. Encoder simulation

You can make use of a permanently integrated encoder simulation feature to make

the actual position value available to additional servo drives or other automation

components.

The encoder simulation is not possible at the same time as the encoder

input<ohne_SSI_t> resp. the step/direction input.

The same interface is used here.

A direction reversal configured in the C3 ServoManager does not affect the

encoder simulation.

The direction of rotation of the encoder simulation can, however, be changed via

the feedback direction in the MotorManager.

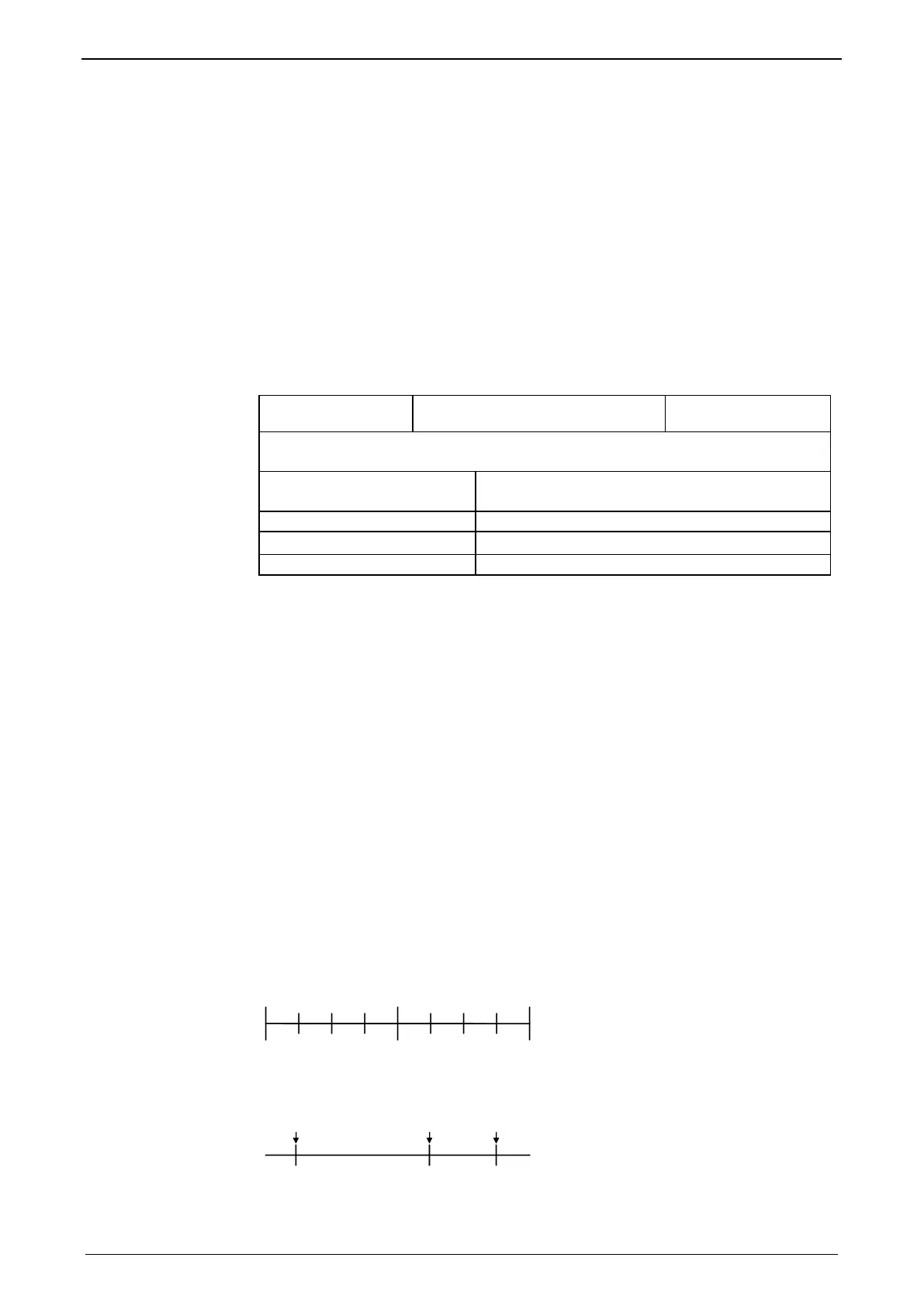

Simulated Encoder Output Resolution

Unit: Increments per

revolution / pitch

Range: 4 - 16384 Standard value: 1024

Any resolution can be set

Limit frequency: 620kHz (track A or B) i.e. , with:

Increments per revolution max. Velocity

1024 36000 rpm

4096 9000 rpm

16384 2250 rpm

4.1.11.1 Encoder bypass with Feedback module F12 (for

direct drives)

If the feedback module F12 is used, the encoder signals can be placed directly

(Bypass) to the encoder interface (X11: same assignment as encoder simulation)

for further use. Sine/Cosine signals are directly converted into encoder signals,

however no additional zero pulse is generated; an available zero pulse will be

transmitted.

The advantage is, that the limit frequency is 5MHz instead of 620kHz (track A or

B).

The direction of rotation is only defined via the encoder wiring; a direction inversion

configured in the C3 ServoManager does not have any consequence.

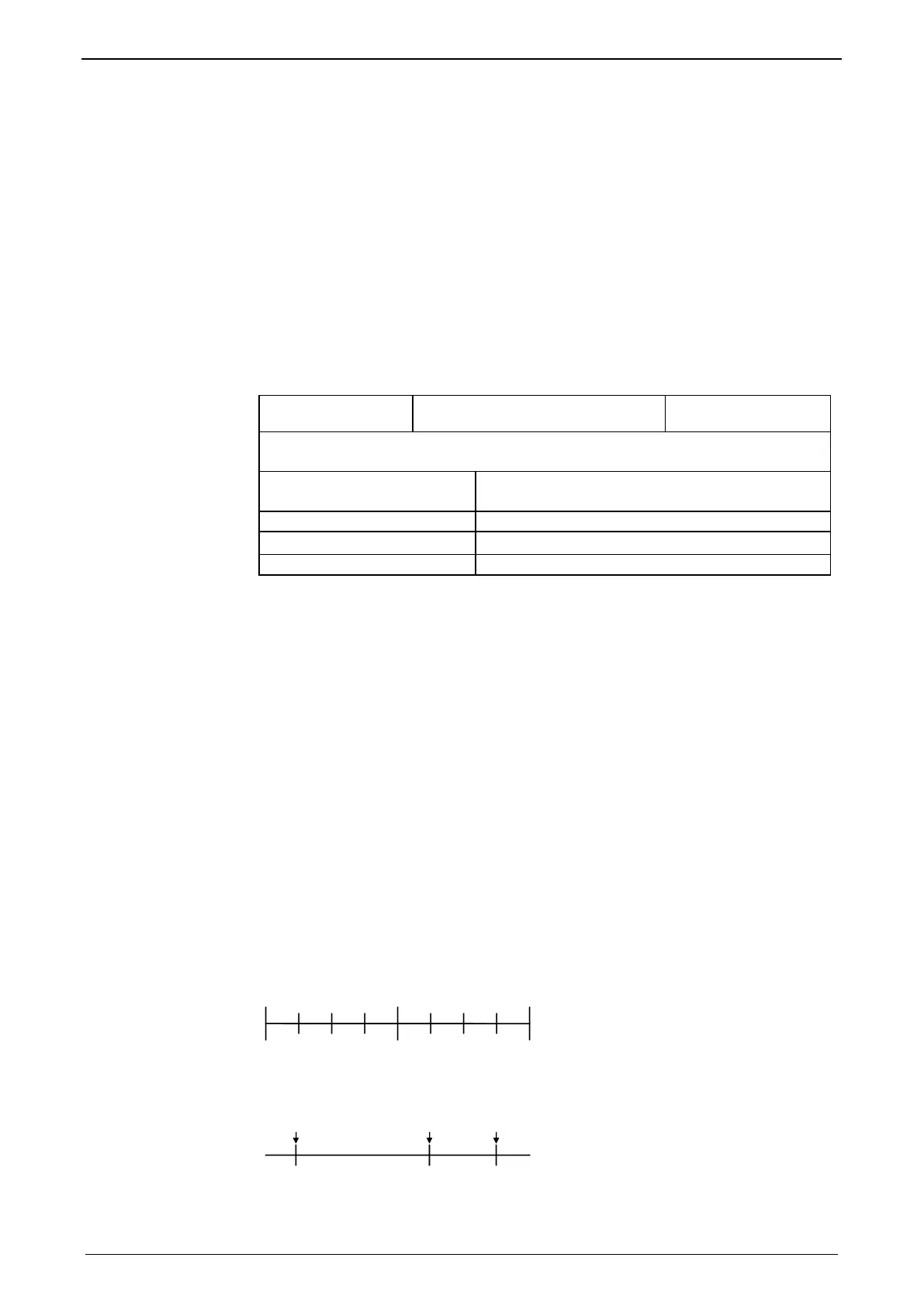

4.1.12. Absolute- /continuous mode

Operating mode: Absolute mode or continuous mode

A fixed measuring system is associated with the travel range: A fixed defined zero

point exists. All positions are referred to this zero point.

-100-200

-300

0

+100 +200 +300

The actual position is set to 0 before each positioning. Thus the travel range has no

fixed zero point. All positionings are relative - in relation to the actual position.

Loading...

Loading...