Setting up Compax3

C3I12T11

192-120113 N08 C3I12T11 - December 2010

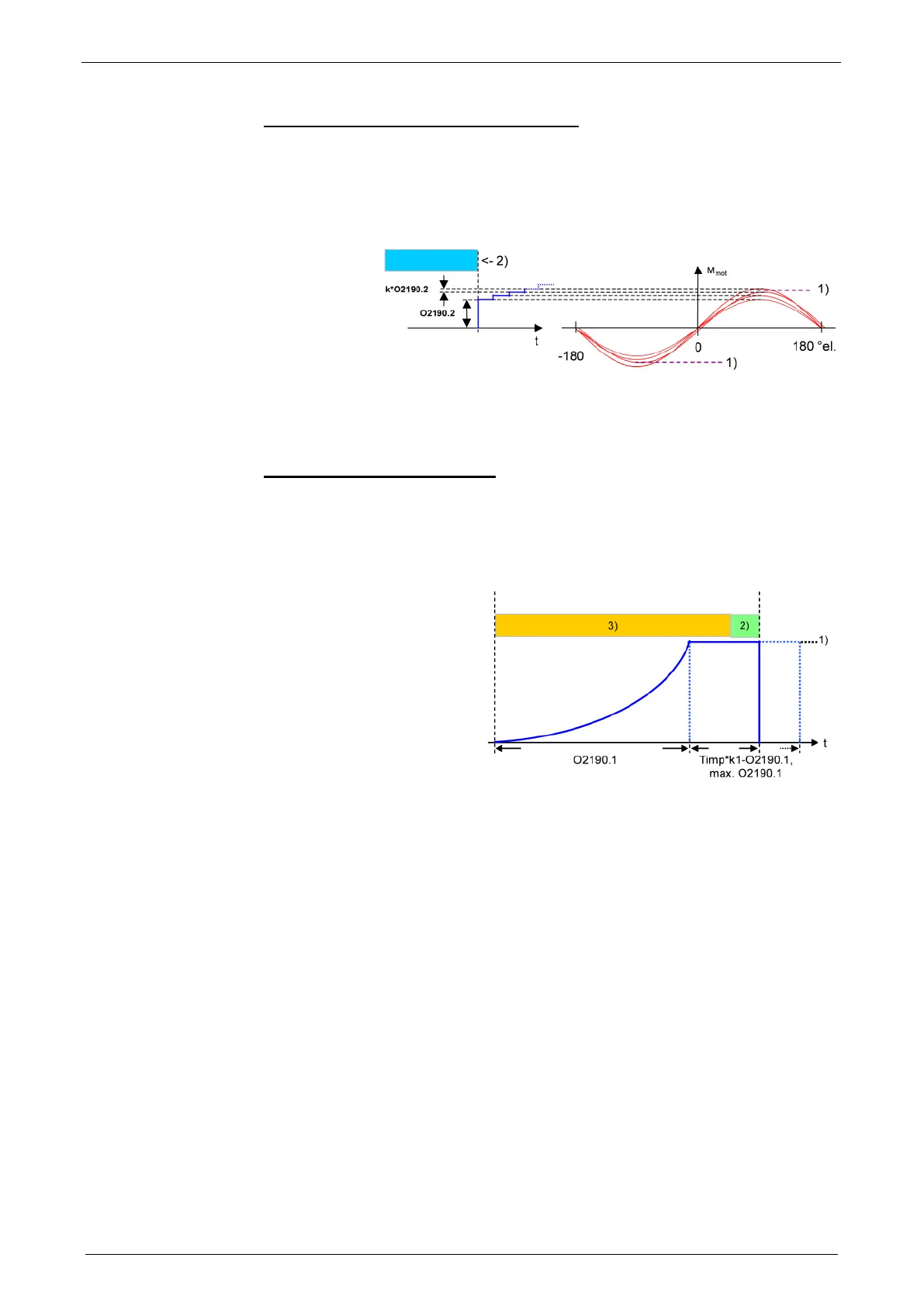

Searching for the torque maxima (phase 1)

If the sum of the actual and the estimated error angle is ±90° electrically, the motor

torque is maximal for the provided current. If you gradually increase the provided

motor current, the motor will, from a defined value on, surpass its friction torque

and exceed a motion threshold defined by O2190.3:

Illustration of the first phase

1): Motion threshold O2190.3

2): Waiting for standstill

O2190.2: Starting current

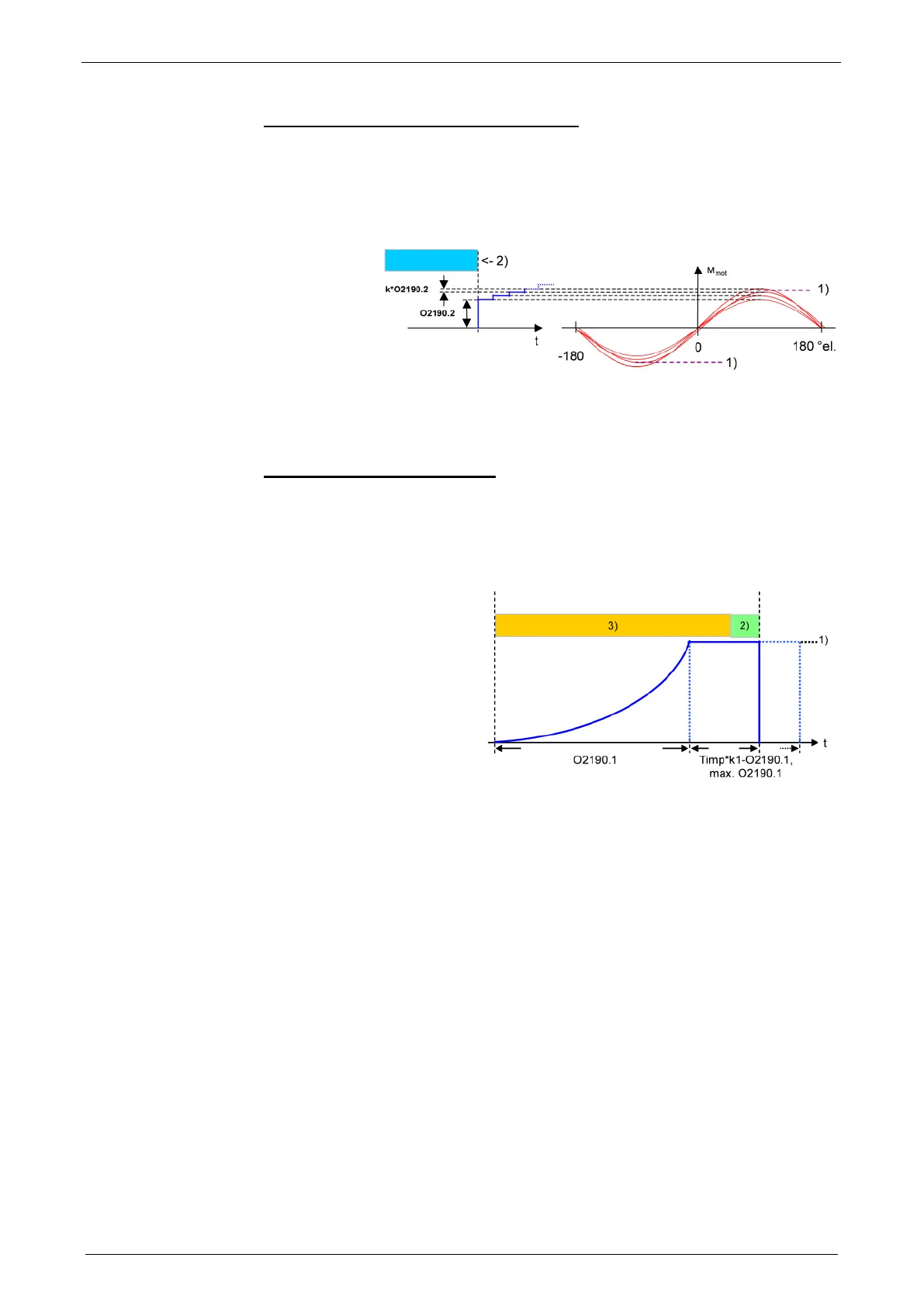

Latching of the motor (phase 2)

Here, the drive is brought to the position with the provided motor torque=0, where

the angular error is either +-180° or 0°.

Current rise in the second phase.

O2190.1: Rising time of latching current

1) Maximum current from controller or motor

2) Monitoring on 5° electrical movement

3) Monitoring on 60° electrical movement

Motion reduction:

It is possible, to considerably reduce the motor movement occurring during the fine

angle search with the aid of the "motion reduction" parameter (O2190.4).

Please respect also that the acquired commutation result may be slightly worse

than without this measure.

As a current well above the nominal motor current is provided here, there may be

saturation effects on iron core motors, which might lead to an instable current loop

(-> highly frequent "creaking noises" during the automatic commutation). This can

be avoided by activating the saturation characteristic line in the motor data.

Loading...

Loading...