Parker EME

Setting up Compax3

192-120113 N08 C3I12T11 - December 2010

Open/Closed Loop frequency response measurement

In order to be able to analyze the transmission behavior of subordinate systems

(such as for example speed control, current control or mechanical system), the

influence of the superposed controls on the measurement must be avoided.

Influence of a superposed system on the frequency response measured

In the simplest case, the superposed controls are switched off completely (Open

Loop) This provides the best measurement results due to the elimination of any

influence caused by the superposed controls.

This is, however, rarely possible for reasons of safety or feasibility.

Caution!

Many systems are not stable without control!

Position as well as speed control are switched off

during measurement =>

no measurement on z-axes!

If you want to analyze for example the mechanic system of a z-axis, the position

control as well as the speed control must remain active.

In systems subject to friction it may be necessary in order to improve the quality of

the measurement, to move the system with a superimposed speed (see on

page 264), which is however only possible with a closed loop measurement.

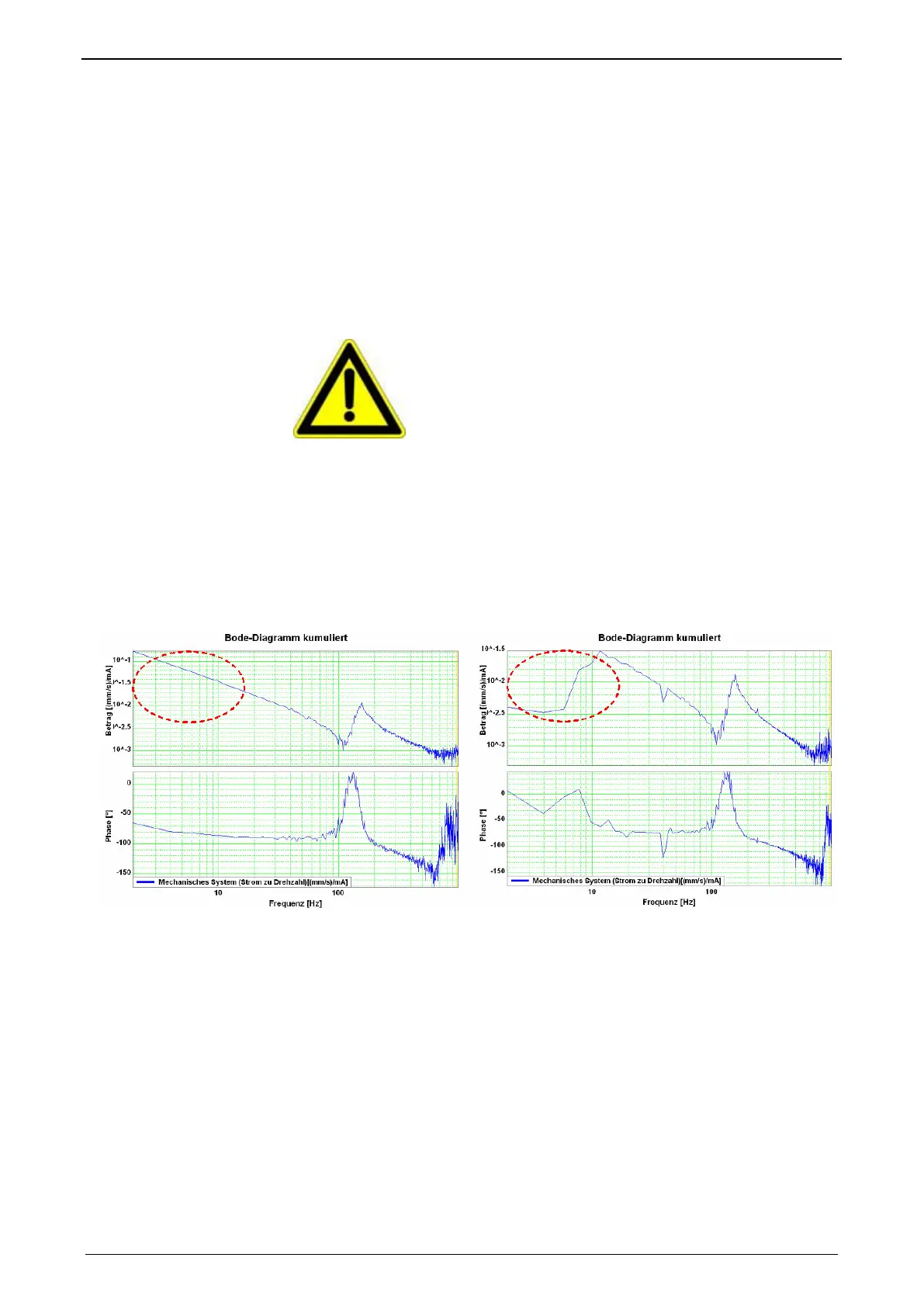

Influence of an active superposed control on the result of the measurement

At the left without, at the right with the influence of the superposed control

In order to attenuate the influence of the superposed controls, the controller

bandwidth is reduced to such an extent, that their influence on the measurement is

negligible.

Loading...

Loading...