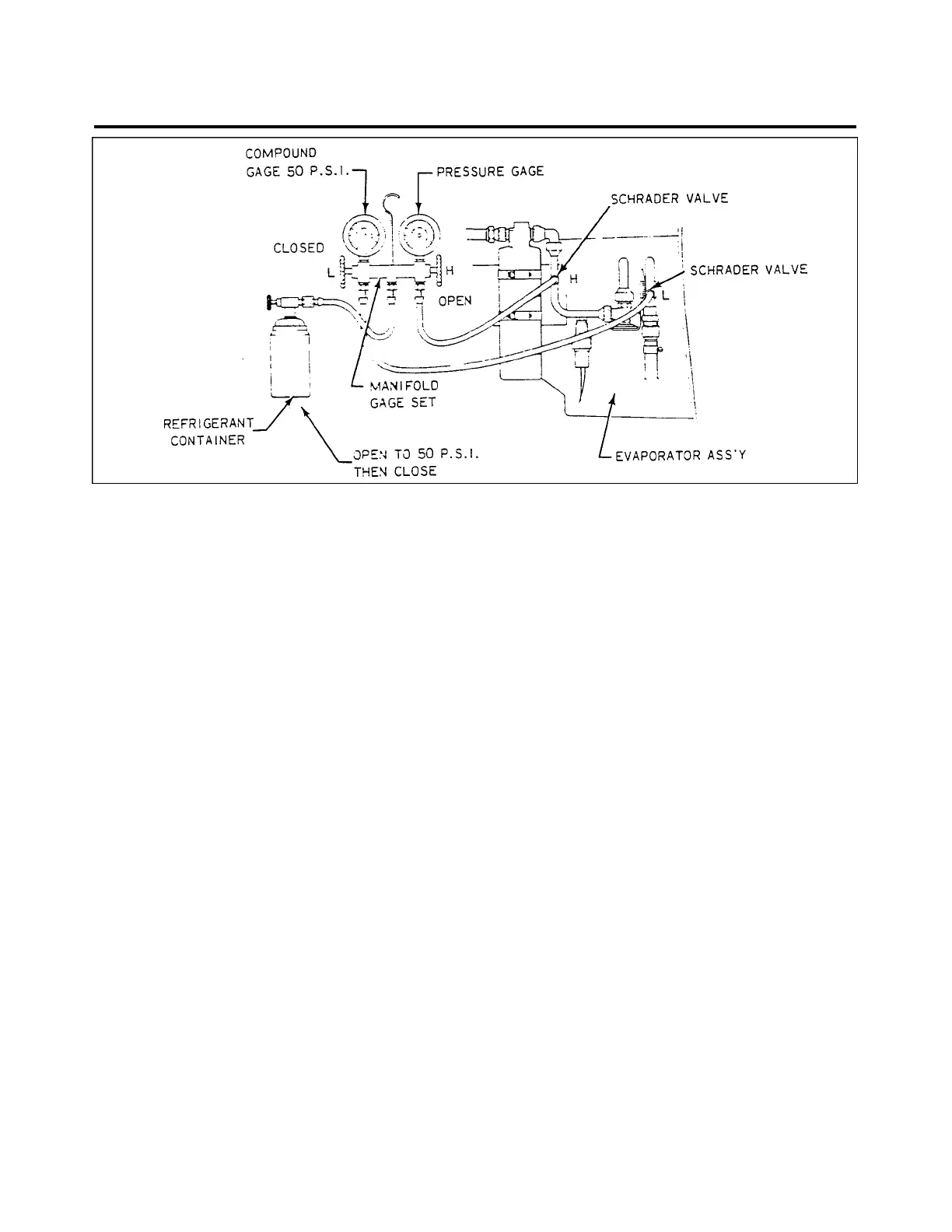

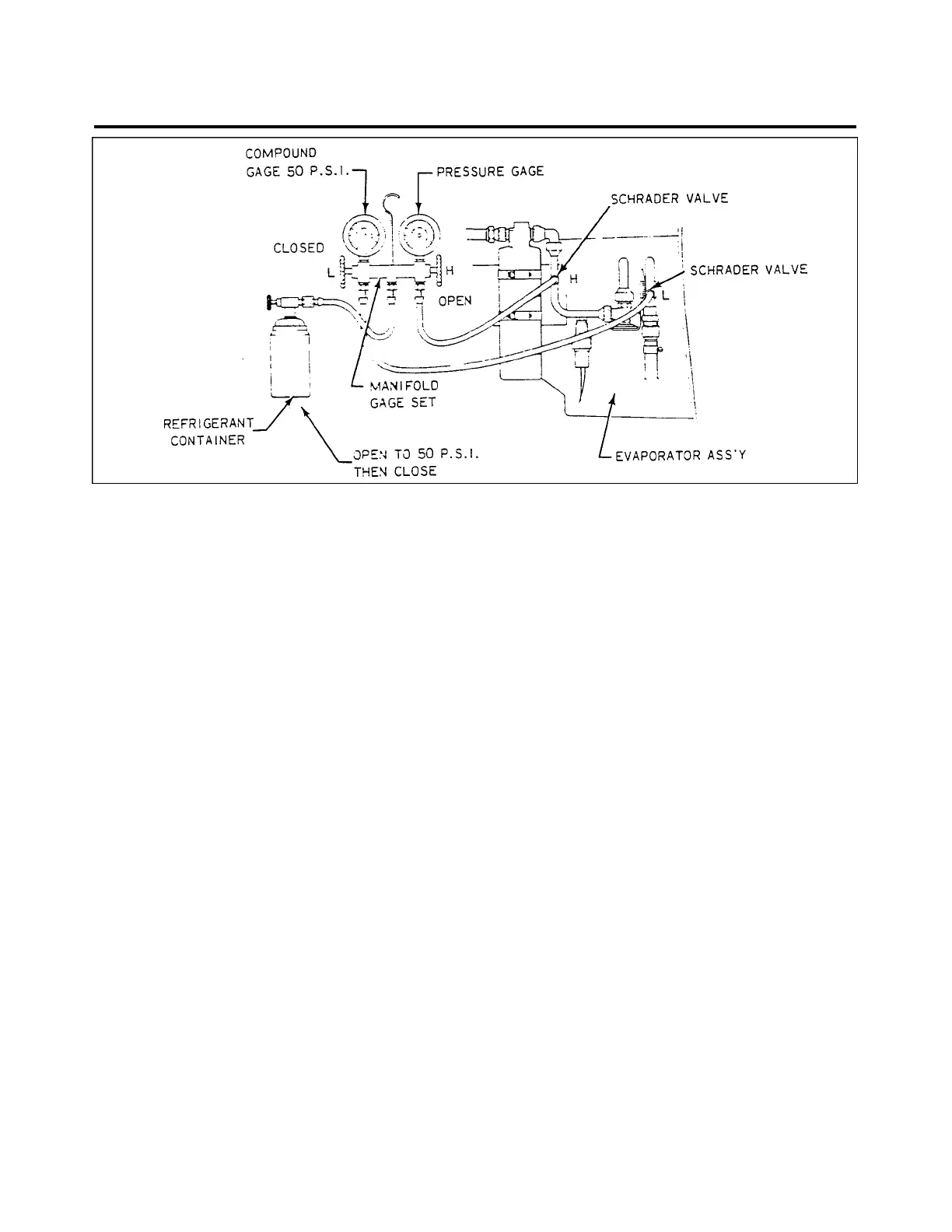

Figure 21b. Leak Test Hookup

—NOTE—

Evacuate system prior to leak check.

LEAK CHECK

A. METHOD I.

1. Connect manifold gauge set to system and determine if there is any refrigerant in system. A minimum

of 50 psi refrigerant pressure in system is needed for leak detection. (Refer to figure 21.6)

2. Purge hoses of air by allowing some refrigerant to escape from connections at service valves. Then,

tighten connections at service valve.

3. Close low side manifold valve and open high side manifold valve.

4. Open refrigerant container service valve and allow pressure at low side gauge to reach 50 psi. Then,

close high side manifold valve.

5. Close refrigerant container service valve and remove hose if no leaks are evident.

—WARNING—

Do not use open flame leak detectors when working on

refrigerant system. Gasoline Vapors in engine compartment could

explode.

—WARNING—

Do not expose Freon to an open flame or high heat. It can

release phosgene gas which can be fatal.

6. Use an electronic leak detector to check system.

7. If any leaks are found, purge system of refrigerant, make necessary repairs, and check compressor oil.

8. Add oil, if required. (Refer to Checking Compressor Oil and chart 2105.) Then, repeat steps 1 thru 5.

9. If no further leaks are found, system may be evacuated and charged. (Refer to Evacuating the System

and Charging the System.)

21 - 52 - 00

Page - 21 - 18

Reissued: August 1, 1986

1G8

PIPER AIRCRAFT

PA-28-236

MAINTENANCE MANUAL

Loading...

Loading...