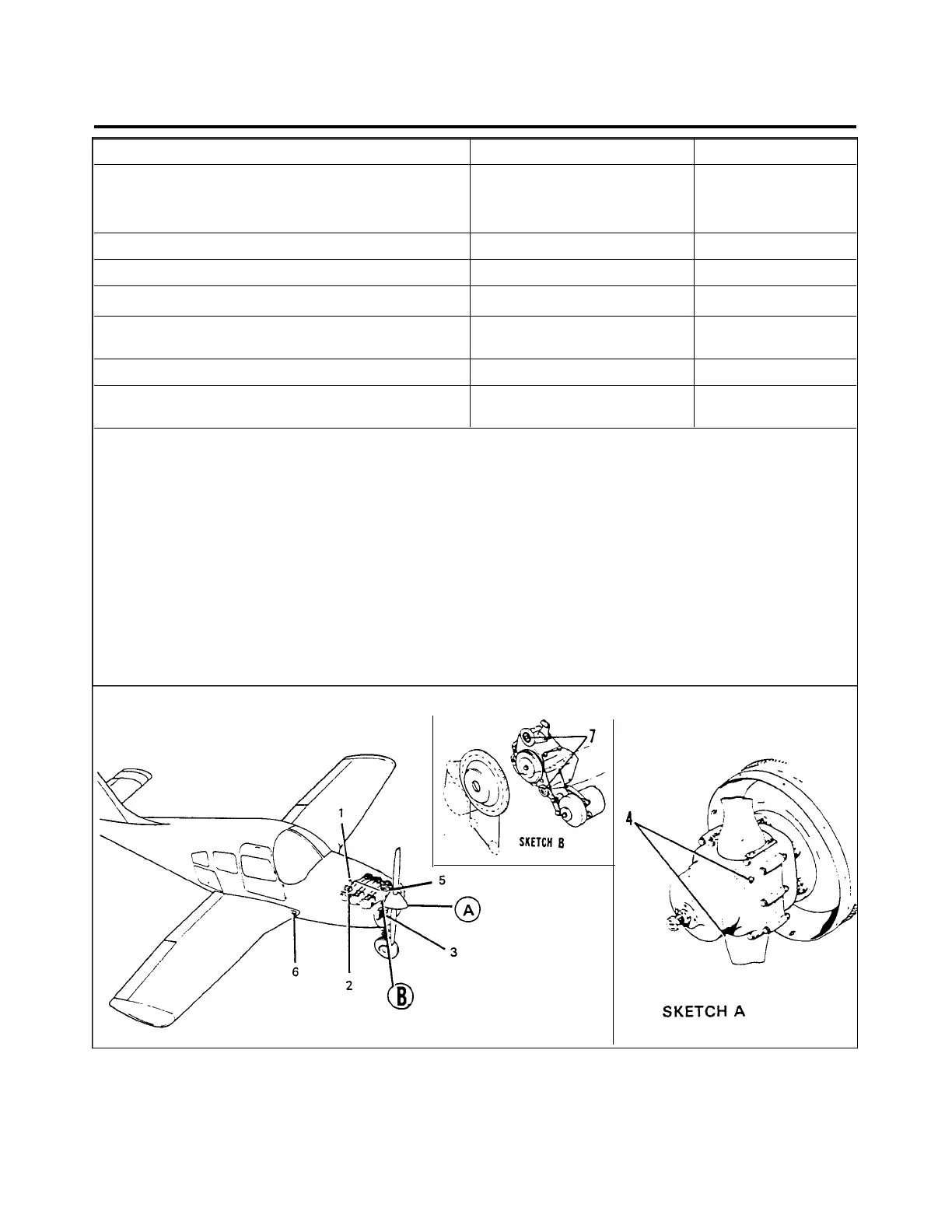

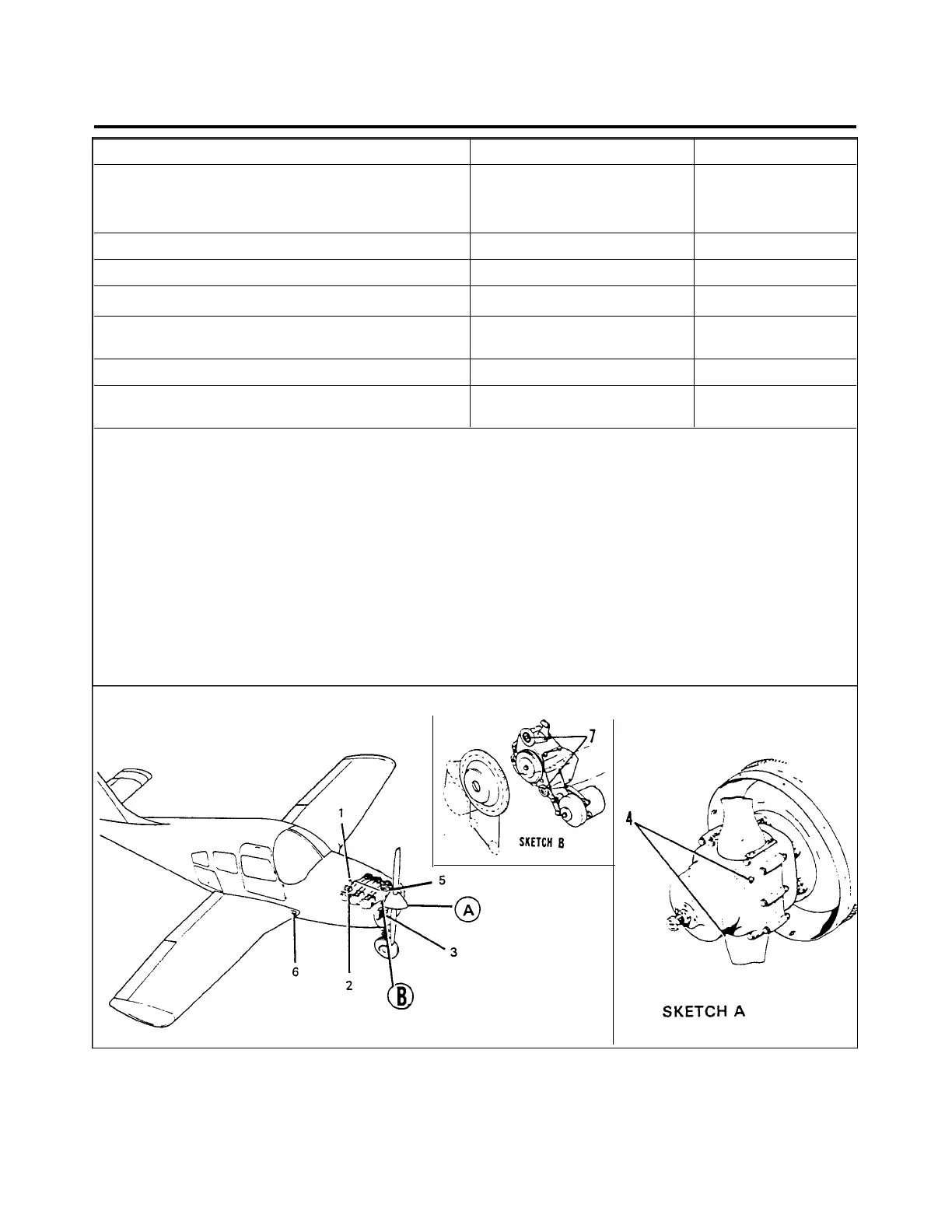

COMPONENT LUBRICANT FREQUENCY

1. ENGINE SUMP MIL-L-6082 MINERAL

1 3

MIL-L-22851

1 3

(ASHLESS DISPERSANT) 50 HRS

2. CARTRIDGE TYPE OIL FILTERS 50 HRS

3. AIR FILTERS 50 HRS

4. PROPELLER ASSEMBLY MIL-G-23827

3

100 HRS

5. ENGINE CONTROL AND ENVIRONMENTAL

CONTROL PIVOT POINTS MIL-L-7870 100 HRS

6. FRESH AIR VENT SHAFTS MIL-G-7711 500 HRS

7. ALTERNATOR AND COMPRESSOR IDLER

PULLEY BEARINGS (IF INSTALLED) MIL-G-81322 100 HRS

SPECIAL INSTRUCTIONS

1. Air Filter - To clean filter, tap gently to remove dirt particles. Do not blow out with compressed air or use oil. Replace filter

if punctured or damaged. Air filter is located on the nose on PA-28-236 model.

2. Intervals between oil changes can be increased as much as 100% on engines equipped with full flow (cartridge type) oil

filters, provided the specified octane fuel is used and the filter replaced each 50 hours of operation. Should fuel other than

the specified octane rating for the power plant be used, refer to latest revision of Lycoming Service Letter No. L185, for

additional information and recommended service procedures.

3. Propeller - Remove one of the two grease fittings for each blade. Apply grease through fitting until fresh grease appears at

hole of removed fitting.

NOTES

1. See the latest revision of Lycoming Service Instructions No.1014 for use of detergent oil.

2. Lubricate alternator idler pulley bearing by removing front grease seal.

3. Refer to Chart 1202 Type of Lubricant.

Figure l2-8. Lubrication Chart (Power Plant, Propeller and Control Pivot Points)

12 - 27 - 00

Page - 12 - 25

Reissued: August 1, 1986

1D21

PIPER AIRCRAFT

PA-28-236

MAINTENANCE MANUAL

Loading...

Loading...