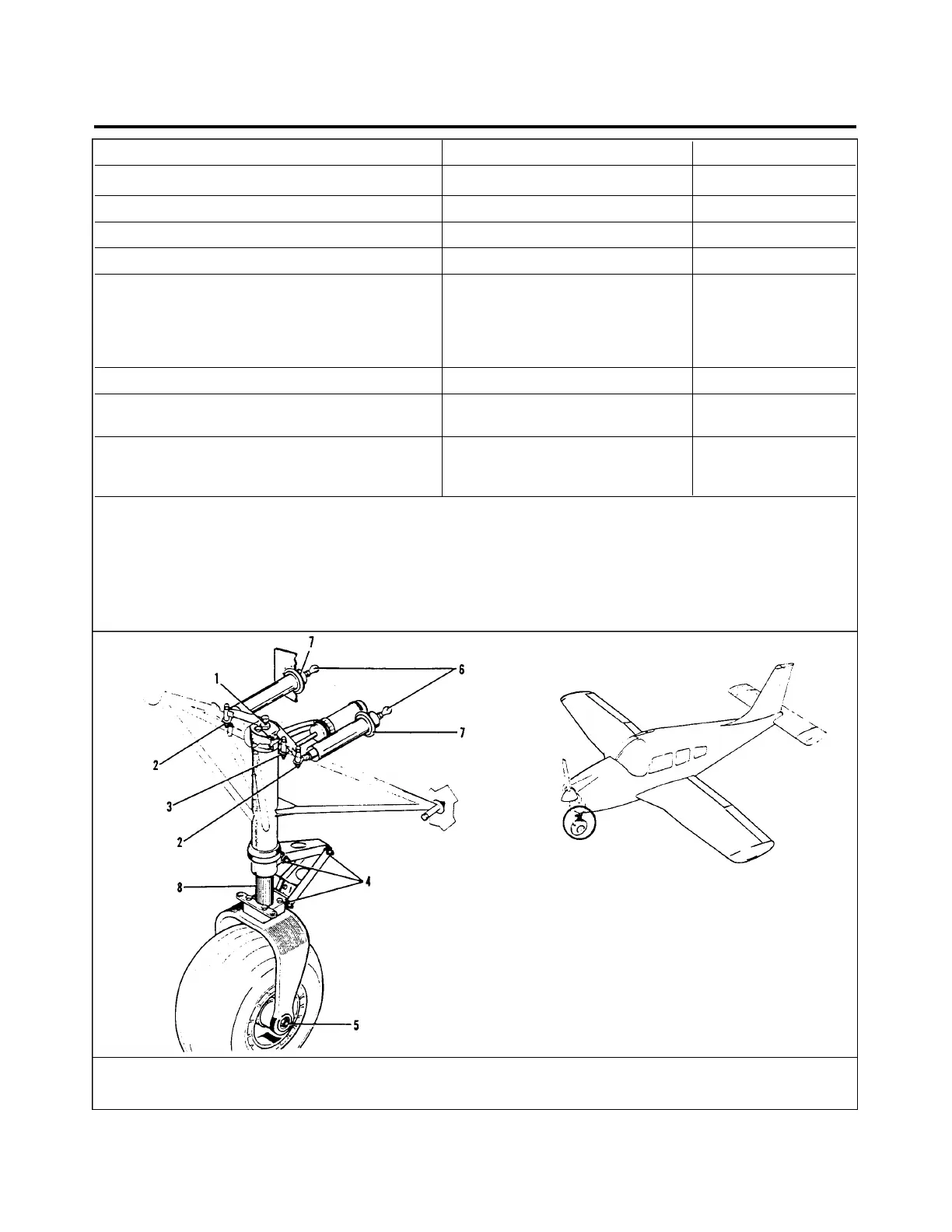

COMPONENT LUBRICANT FREQUENCY

1. OLEO STRUT FILLER POINT MIL-H-6606

2

AS REQUIRED

2. STEERING BELLCRANK PIVOT POINT MIL-G-7711 100 HRS

3. SHIMMY DAMPENER PIVOT POINT MIL-L-7711 100 HRS

4. TORQUE LINK ASSEMBLY MIL-L-7870 100 HRS

5. NOSE WHEEL BEARING TEXACO MARFAX ALL

PURPOSE GREASE OR

MOBIL GREASE 77 (OR

MOBILUX EP2 GREASE) OR

SHELL ALVANIA EP GREASE 2 100 HR

6. NOSE GEAR STEERING ROD END BEARINGS MIL-G-7711 100 HRS

7. BUNGEE SEAL PARKER O-RING 3

LUBRICANT 100 HRS

8. EXPOSED OLEO STRUT FLUOROCARBON RELEASE

AGENT DRY LU8RICANT

MS-122 100 HRS

SPECIAL INSTRUCTIONS

1. Nose Wheel Bearings - Disassemble and clean with a dry type solvent. Ascertain that grease is packed between the roller and

cone. Do not pack grease in wheel housing. Wheel bearings require cleaning and repacking after exposure to an abnormal

quantity of water.

2. Oleo Struts - Fill per instructions on unit or refer to instructions in this chapter.

3. Bungee - Lubricate springs if Bungee is disassembled. (Use Lubriplate #907 or Aero Shell Grease #7.)

Figure l2-5. Lubrication Chart (Landing Gear, Nose)

12 - 27 - 00

Page - 12 - 19

Reissued: August 1, 1986

1D15

PIPER AIRCRAFT

PA-28-236

MAINTENANCE MANUAL

Loading...

Loading...