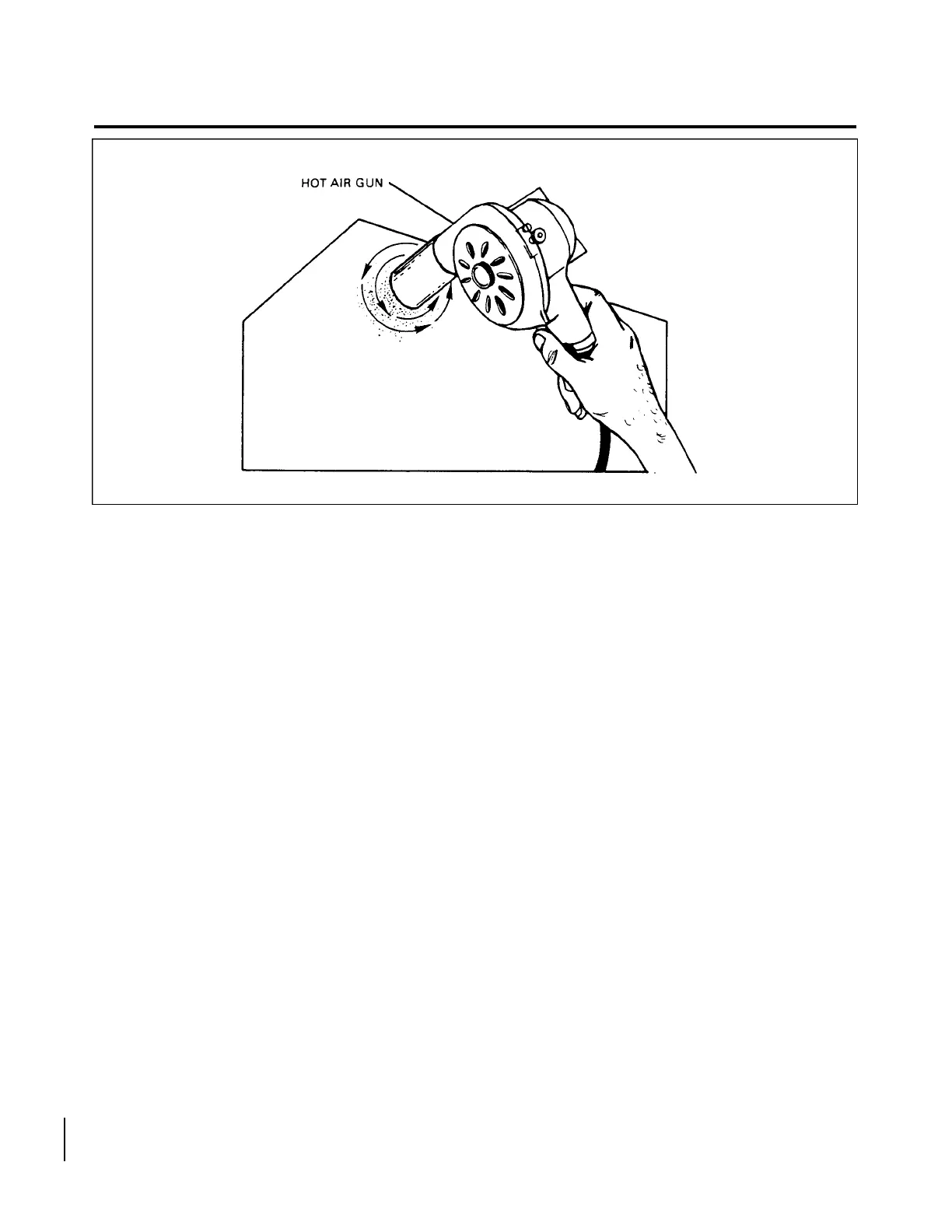

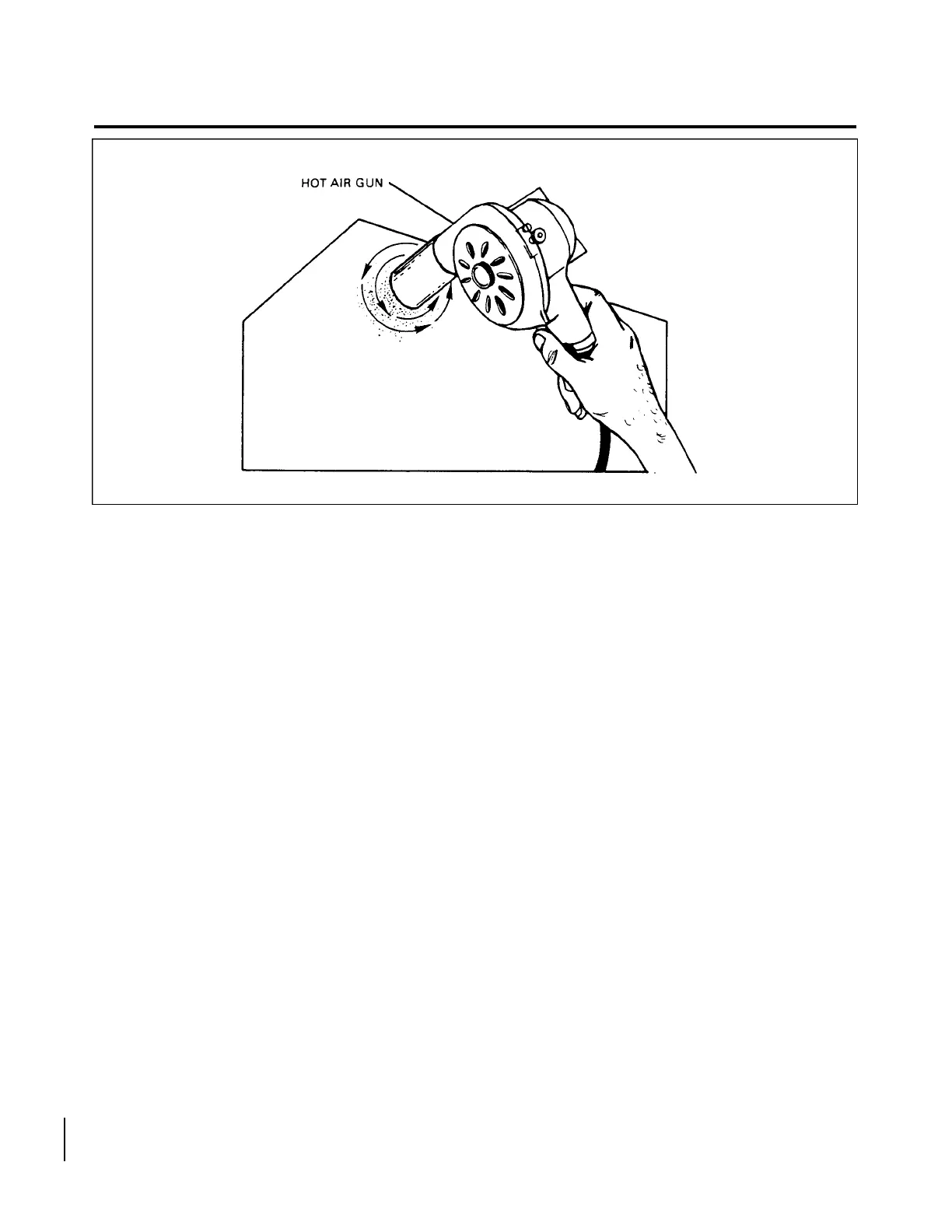

Figure 51-2. Surface Scratches, Abrasions or Ground-in-Dirt

1. Surface preparation:

a. Surface dirt and paint if applied must be removed from item being repaired.

b. Preliminary cleaning of damaged area with perchlorethylene or VM-P Naphtha will ensure a good

bond between epoxy compounds and thermoplastic.

2. Surface scratches, abrasion or ground-in-dirt: (figure 51-2)

a. Shallow scratches and abraded surfaces are repaired using conventional automotive buffing and

rubbing compounds.

—CAUTION—

When using a hot air gun, be carfeul not to overheat the

thermoplastic

b. Remove large dirt particles embedded in thermoplastic parts with a hot air gun capable of

supplying heat in the temperature range of 300° to 400° F. Hold nozzle of gun about 1/4 inch

away from surface and apply heat until area is sufficiently soft to remove dirt particles.

—NOTE—

Thermoplastic will return to its original shape upon cooling.

3. Deep scratches, shallow nicks, and small holes: (Less than 1 inch in diameter.) (figure 51-3)

a. Solvent cements will fit virtually any of these applications. If area to be repaired is very small, it

may be quicker to make a satisfactory cement by dissolving thermoplastic material of same type

being repaired in solvent until desired paste-like consistency is achieved.

b. Apply mixture to damaged area. When the solvent evaporates, the hard solids remaining can easily

be shaped to desired contour by filing or sanding.

c. Solvent adhesives are not recommended for highly stressed areas, on thin walled parts or for

patching holes greater than 1/4 inch in diameter.

51 - 12 - 00

Page 51 - 09

Reissued: August 1, 1986

2F5

PIPER AIRCRAFT

PA-28-236

MAINTENANCE MANUAL

Loading...

Loading...