GENERAL

TORQUE REQUIREMENTS

The torque values in chart 9102 are derived from oil-free cadmium-plated threads and are recommended

for all airframe installation procedures where torquing is required, unless otherwise noted in sections where

other values are stipulated. Engine torque values are found in the latest revision of Lycoming Overhaul

Manual, and propeller torque values are found in chapter 6l of this manual. Chart 9l0l lists the torque values

for flared fittings of various sizes and material.

—CAUTION—

Do not overtorque fittings.

—NOTE—

When flared fittings are being installed, ensure that the male

threads are properly lubricated. Tighten fittings in accordance

with chart 9101.

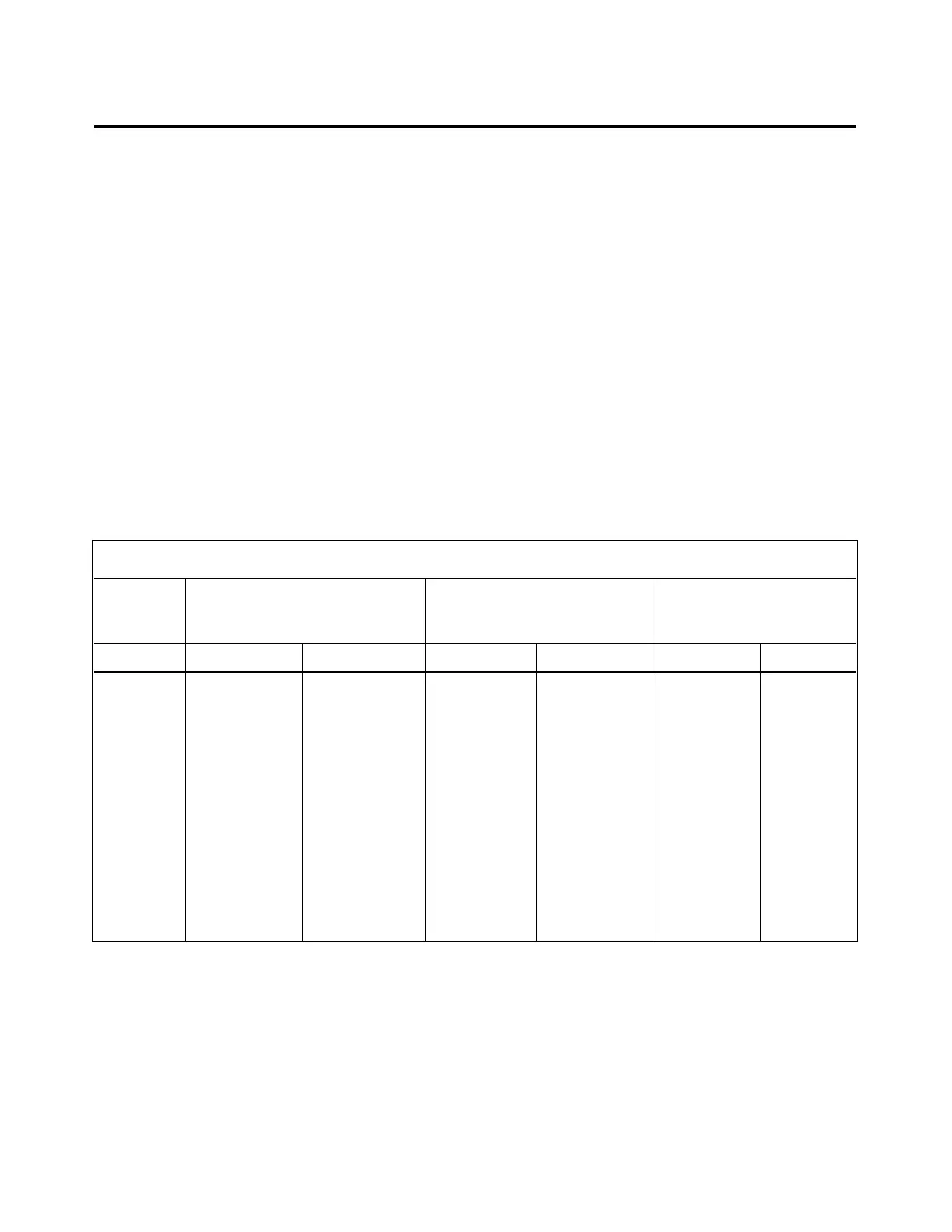

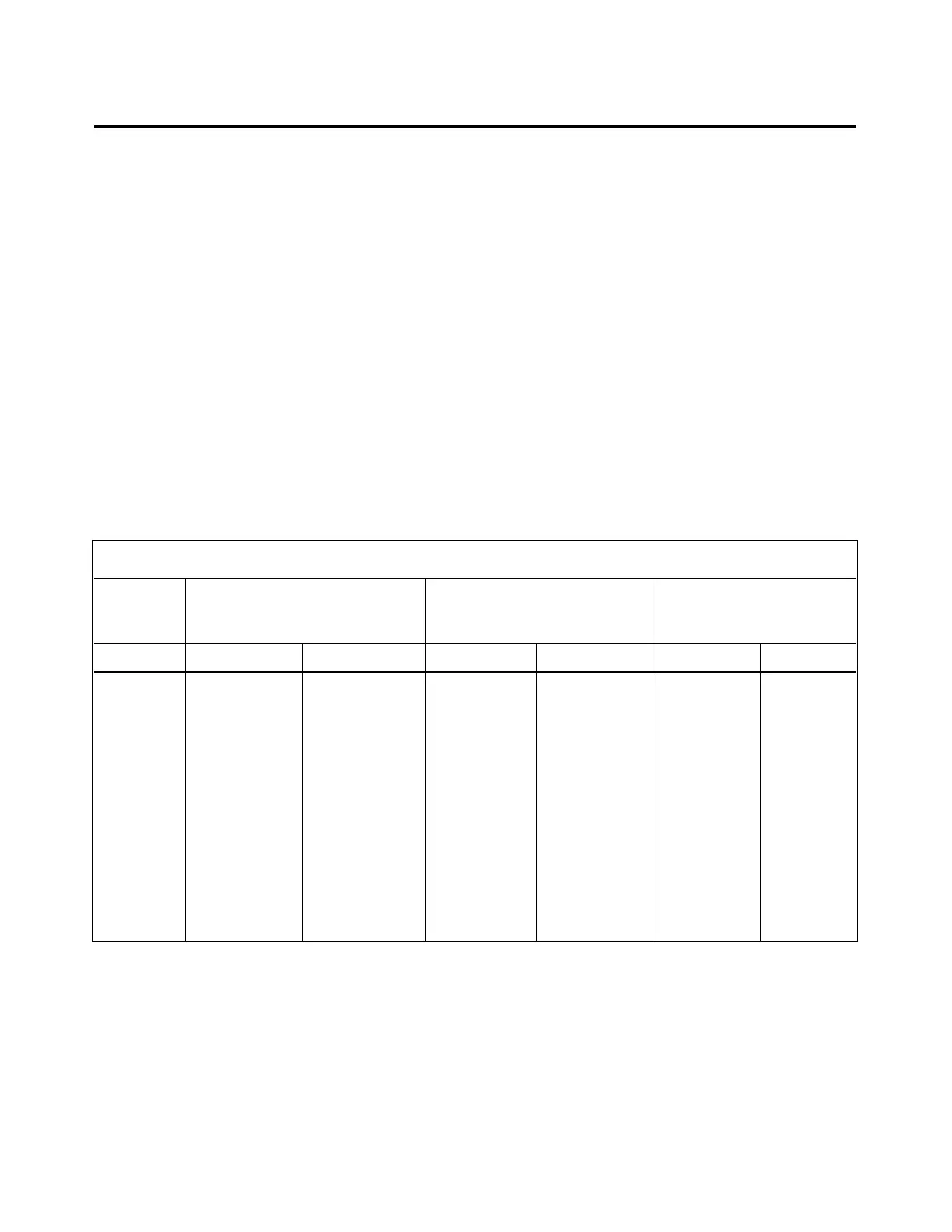

CHART 9101. FLARE FITTING TORQUES

TORQUE—INCH-POUND

TUBING ALUMINUM - ALLOY STEEL TUBING HOSE END FITTING

OD TUBING FLARE - AND FLARE AND

INCHES l006l OR AND l0078 AND l006l HOSE ASSEMBLIES

MINIMUM MAXIMUM MINIMIM MAXIMUM MINIMUM MAXIMUM

l/8 — — — — — — — — — — — — — — — — — —

3/ l6 — — — — — — 90 l00 70 l00

l/4 40 65 l35 l50 70 l20

5/ l6 60 80 l80 200 85 180

3/8 75 l25 270 300 100 250

1/2 l50 250 450 500 2l0 420

5/8 200 350 650 700 300 480

3/4 300 500 900 l000 500 850

1 500 700 l200 l400 700 l l50

1-1/4 600 900 — — — — — — — — — — — —

1-1/2 600 900 — — — — — — — — — — — —

1-3/4 — — — — — — — — — — — — — — — — — —

2 — — — — — — — — — — — — — — — — — —

91 - 01 - 00

Page 91 - 01

Reissued: August 1, 1986

3A19

PIPER AIRCRAFT

PA-28-236

MAINTENANCE MANUAL

Loading...

Loading...