CHECKING ALTERNATOR BELT TENSION

An improperly tensioned belt may wear rapidly or slip, reducing alternator output. Check belt for proper

tension when installed, at 25 hours of operation, and every l00 hours thereafter.

—NOTE—

For aircraft with air conditioning installed, refer to chapter 21,

for replacement and adjustment of compressor drive belt.

There are three methods of checking alternator belt tension; the first method is preferable because it is

technically simple and requires little time.

l. Torque Method: This method of checking belt tension consists of measuring torque required to

slip belt at small pulley:

a. Apply a torque indicating wrench to nut that attaches pulley to alternator and turn it in a clockwise

direction. Observe torque shown on the wrench at instant pulley slips.

b. Check torque indicated in step a. with torque specified in chart 2404. Adjust belt tension

accordingly.

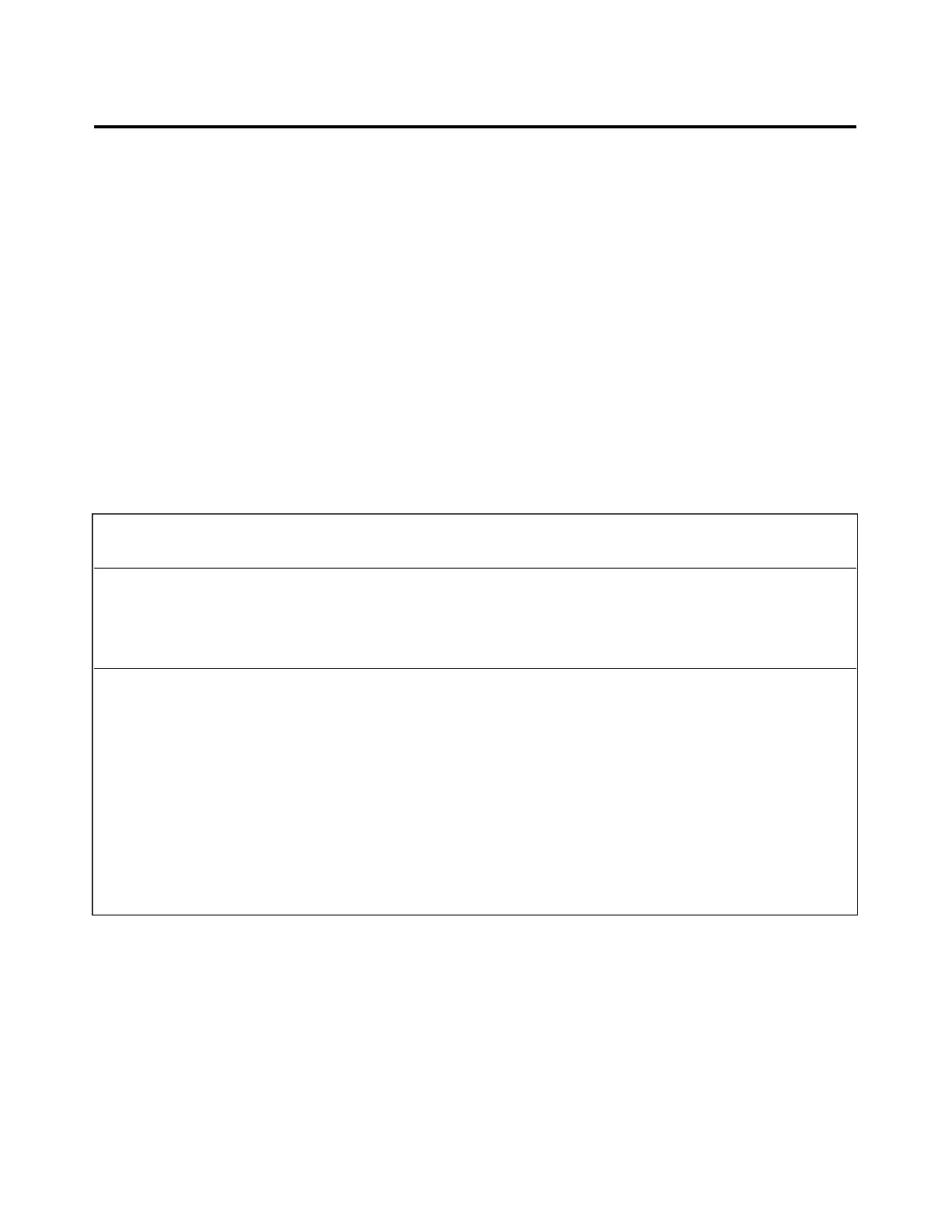

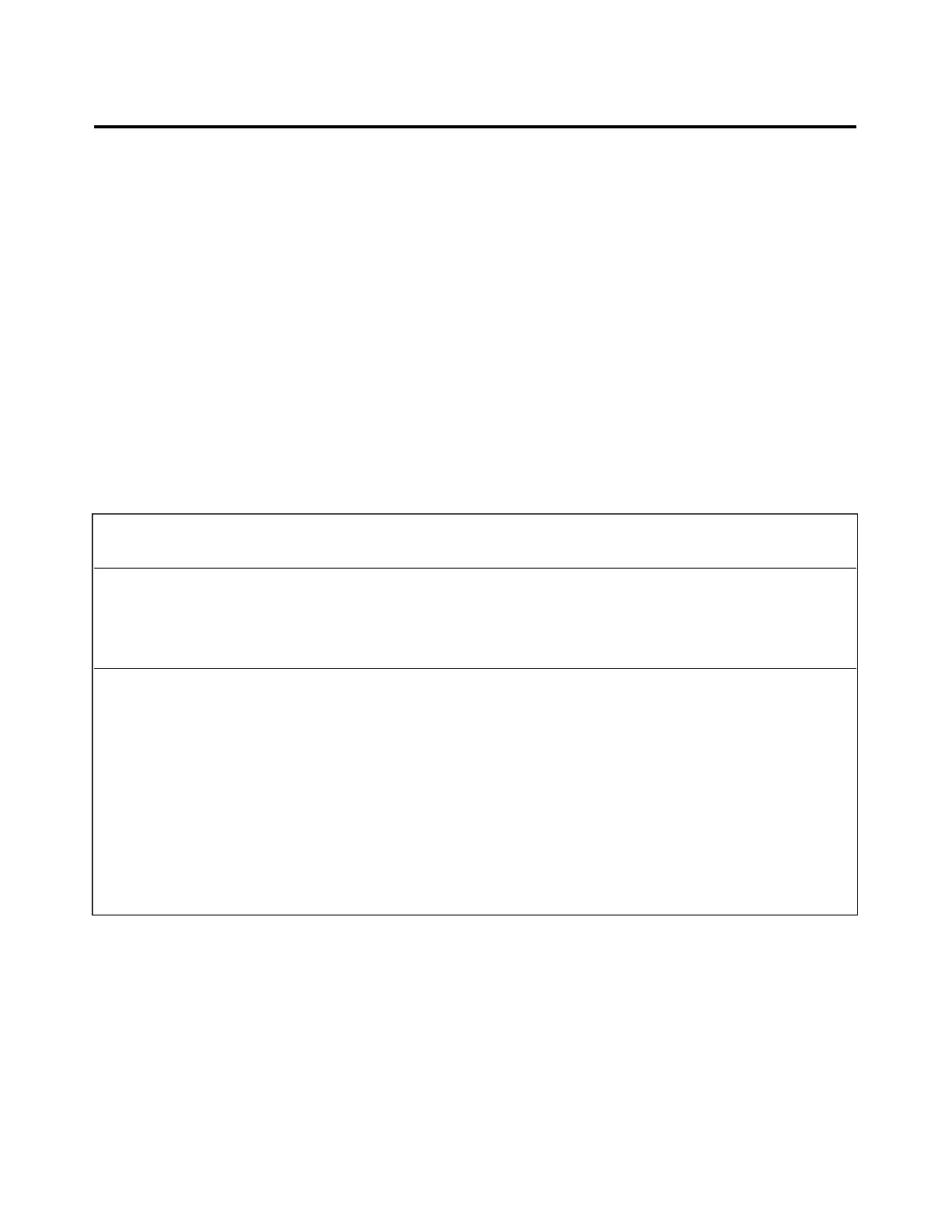

CHART 2404. ALTERNATOR BELT TENSION

Torque indicated at

Width of Belt Condition alternator pulley

3/8 inch New l1 to 13 ft-lbs

3/8 inch Used 7 to 9 ft-lbs

1/2 inch New 13 to 15 ft-lbs

1/2 inch Used 9 to 11 ft-lbs

—NOTE—

The higher tension specified for a new belt is to compensate for

initial stretch that takes place as soon as it is operated. These

higher tension values should not be applied to belts which have

been used previously.

—NOTE—

Chrysler alternators do not have a nut on the shaft and therefore

cannot be checked by this method.

24 - 33 - 00

Page - 24 - 36

Reissued: August 1, 1986

1J11

PIPER AIRCRAFT

PA-28-236

MAINTENANCE MANUAL

Loading...

Loading...