CIRAS-3 Operation Manual V. 1.09 194 support@ppsystems.com

When the leaf cuvettes are not in use, remember to leave the cuvette head open to avoid compression of

the leaf gaskets.

PLC3 Universal Gaskets, 18 mm diameter (Qty. 10)

PLC3 Universal Gaskets, 25 mm x 18 mm (Qty. 10)

PLC3 Universal Gaskets, 25 mm x 7 mm (Qty. 10)

PLC3 Universal Rear Gaskets, 50 mm x 35 mm (Qty. 10)

PLC3 Narrow/Conifer Gaskets, 88 mm x 40 mm (Qty. 10)

Checking For Leaks Associated With the PLC3

How do I know if there is a leak in the system? Good

question. If you have the leaf cuvette closed with no leaf

present, you should observe a CO

2

differential (CO2d) close

to 0 (± 0.5 µmol mol

-1

and stable). If your CO2d is this and

fluctuating this usually is the result of a leak. To help isolate

the leak and to determine if the leak is associated with the

CIRAS-3 console or the PLC3, we include a simple “Leaf

Cuvette Simulator” (Part No. STD553) with each new system

that can be very helpful.

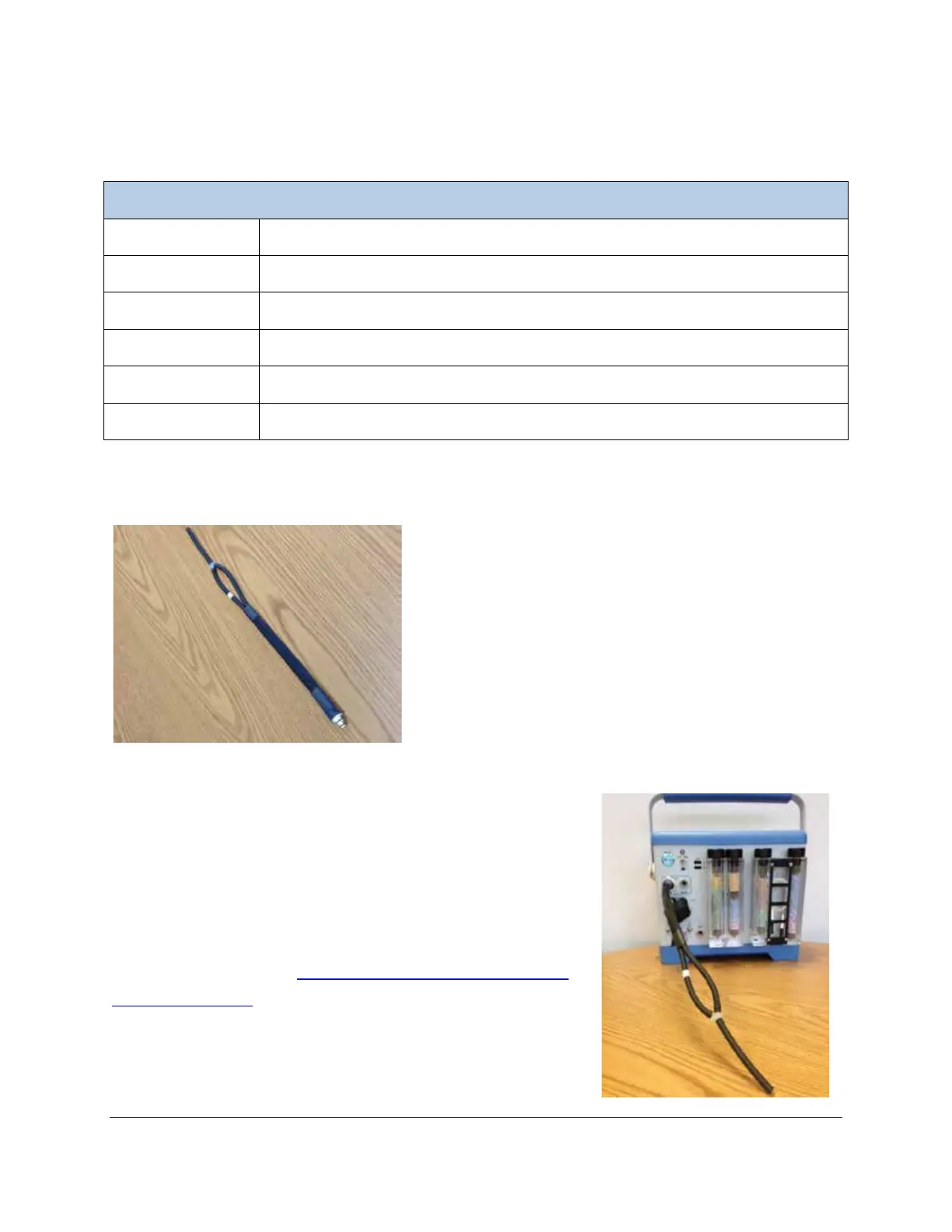

To checks for leaks, connect the cuvette simulator to the PLC Gas

port on the CIRAS-3 console as shown here to the right. This will

allow you to sample the same air in both the reference and analysis

cells of the infrared gas analyzer. When the simulator is connected

to the CIRAS-3 you should observe stable CO2r, CO2a, H2Or and

H2Oa readings and the CO

2

differential (CO2d) should be close to 0

(± 0.5 µmol mol

-1

and stable). For more information on checking for

stability and leaks, refer to

Checking Stability - Before You Place a

Leaf in the Chamber on page 70.

If you observe a CO2d value close to 0 and stable with the Leaf

Cuvette Simulator and you do not when the PLC3 leaf cuvette is

connected to the CIRAS-3, the leak is likely associated with the

Simulator

Loading...

Loading...