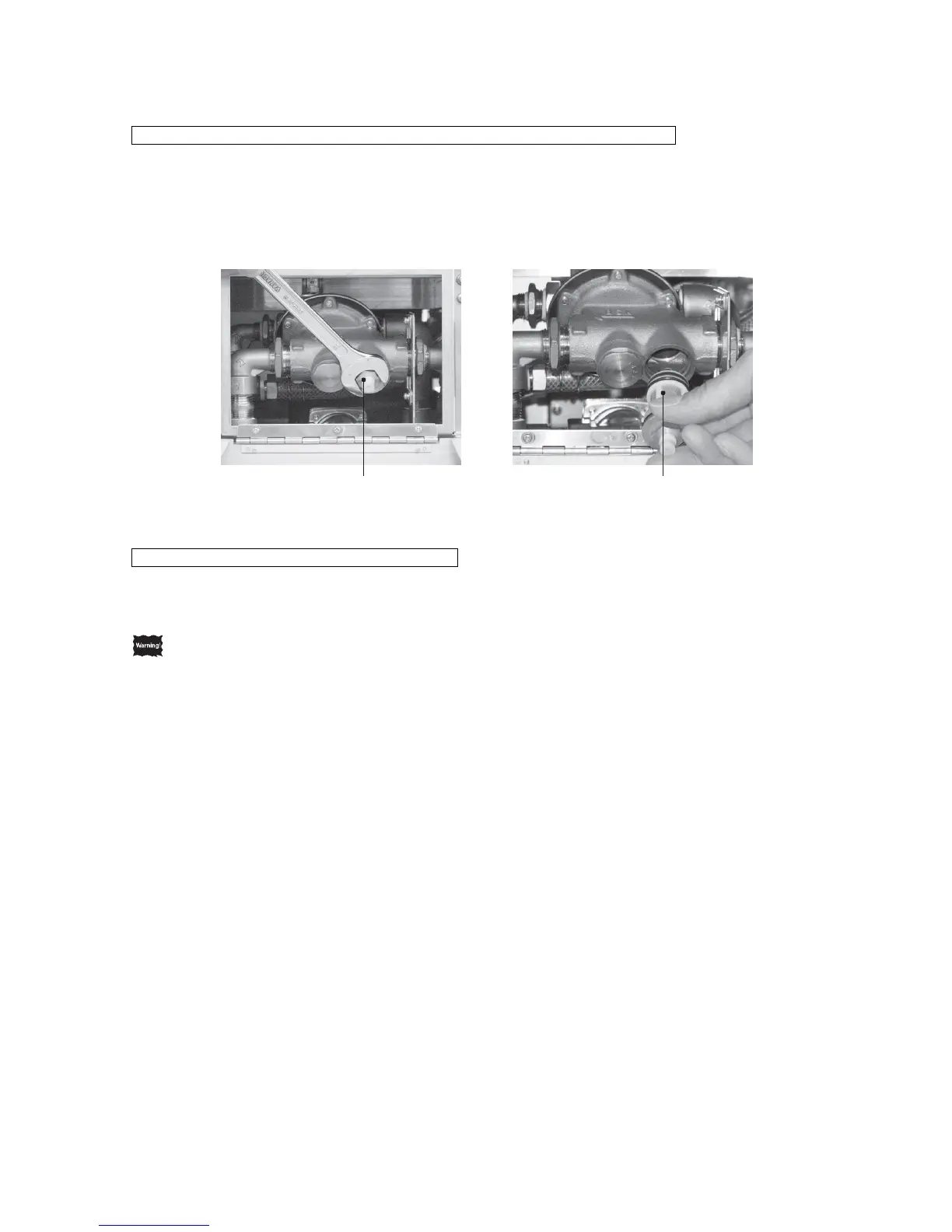

Close the main water valve. Open the water supply strainer door at the bottom right of the system.

Opening the cover makes opening the door easier. Use a wrench of 17 mm across flats to turn the lid

counterclockwise and remove the lid. Water in the pipe will come out, so use a container, etc., to catch the

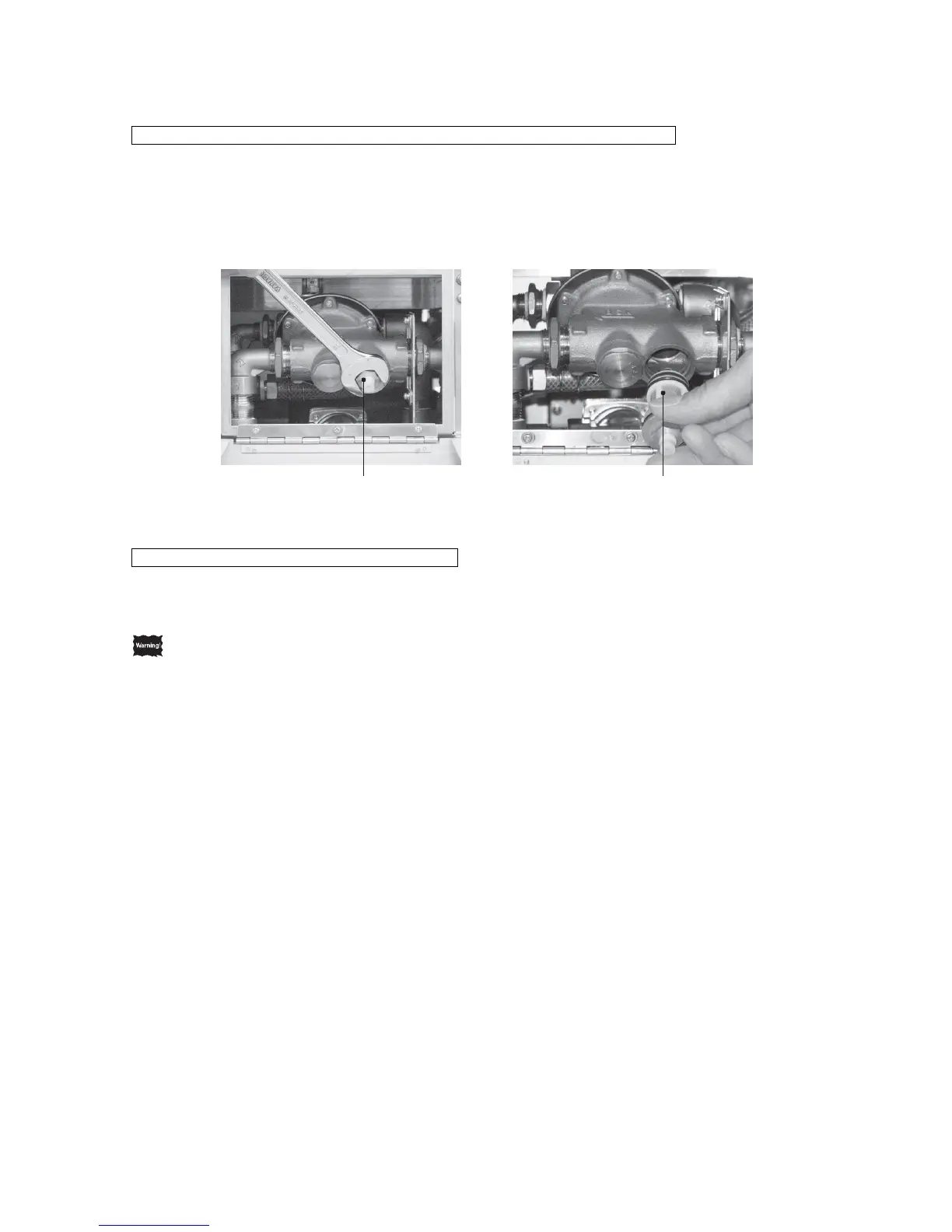

water. Wash the strainer with water using a brush, etc. After washing the strainer, dry and assemble the

strainer, and screw in the lid. Open the water supply plug and confirm that no water leaks from the

strainer. Clean the strainer once a month or so. After the cleaning, perform a water supply test by referring

to

P. 1-42.

Clean the entire storage space for the system and solution stations as well as the sink and pans at least

once a month. Remove all trays from the cabinet and clean them using a cloth moistened with water. Also

clean the trays with neutral detergent, and then wipe down with a dry cloth.

In addition to the interior of the instrument, also clean the cover, door and around the exhaust port

regularly. At this time, be sure to turn off the power and disconnect the power plug from the power

outlet. Failure to do so may result in electric shock.

<Corrosion Protection>

The Tissue-Tek Prisma uses corrosion-resistant stainless steel, but the stainless steel may rust depending

on a combination of factors such as the environment (water, air), staining method (type of solution,

concentration), use method (handling of solvent, maintenance), etc. Take note of the following points to

protect the instrument from corrosion.

Keep the solution reservoir lids closed except during the staining process. Remove those solution

reservoirs containing highly corrosive solutions, from the trays, and keep the solutions outside the

instrument. If a highly corrosive solution spilled in the instrument, wipe it off immediately.

Remove all solution trays (including the solution reservoirs) from the instrument once a week or so, wipe

down the trays using a cloth moistened with water, clean them with neutral detergent, and wipe down with

a dry cloth.

Corrosive solutions

Acids [hydrochloric acid (HCL), hydrobromic acid (Hbr), hydrofluoric acid (HF), etc.] and staining

solutions containing an acid

Reagent solutions [Schiff’s reagent, cold Schiff, sulfurous acid solution, resorcin‐fuchsin staining

solution, etc.]

Oxidizing chlorides [ferric chloride (FeCl3), sodium tiosulfate (Na22O3), organic acid (HCOOH), acetic

acid (CH3COOH), bromic acid (C204H2), lactic acid (CH3CH(OH)COOH), etc.)]

If this is not performed, the metal parts may corrode (rust, etc.) quickly. Contact the Sakura Finetek

Technical Support representative or local representative for use of metal cleaners.

Loading...

Loading...