System description

FLOWSIC100 Flare-XT · Operating Instructions · 8023761/V 1-0/2020-10 · © SICK Engineering GmbH 17

3.2

Functional principle

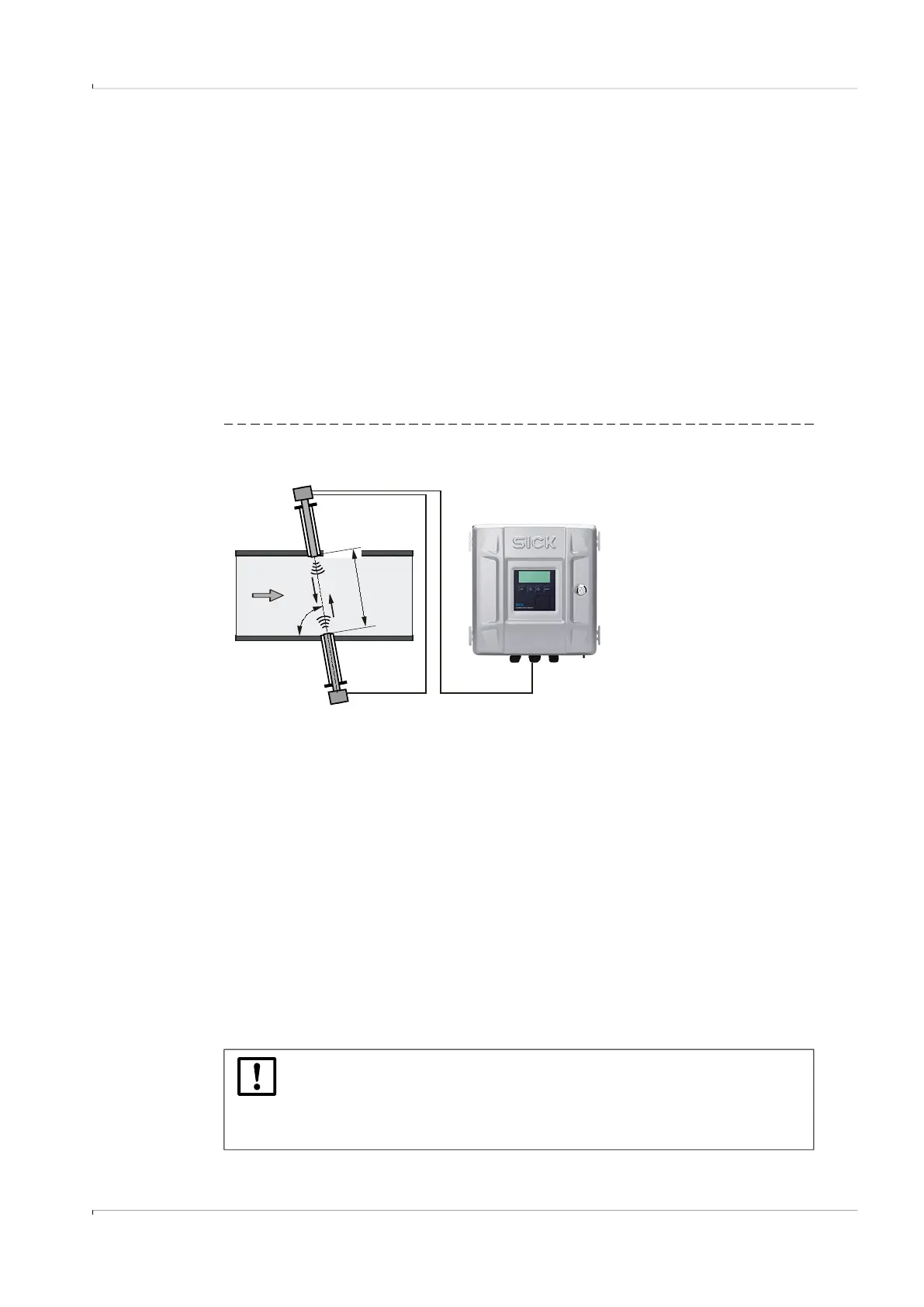

The FLOWSIC100 Flare-XT gas flow rate measuring devices operate according to the

principle of ultrasonic transit time difference measurement. Sender/receiver units are

mounted on both sides of a pipeline at a certain angle of inclination to the gas flow (Fig. 1).

These sender/receiver units contain piezoelectric ultrasonic transducers that function

alternately as senders and receivers. The sound pulses are emitted at an angle to the

flow direction of the gas. Depending on angle α and gas flow rate v, the transit time of the

respective sound direction varies as a result of certain ”acceleration and braking effects”.

The higher the gas velocity and the smaller the angle to the flow direction, the more the

transit times of the sound pulses differ.

Gas flow rate v is calculated from the difference between both transit times, independent of

the sound velocity value. With this measuring method, changes of the sound velocity due to

pressure or temperature variations therefore have no influence on the gas velocity

determined.

Fig. 1 Functional principle FLOWSIC100 Flare-XT

Linearization

Further process values are required to calculate mass flow, molecular weight, gas density

and Reynolds number. Especially pressure, temperature and viscosity have a significant

influence. The best accuracy is achieved when externally installed pressure and tempera-

ture sensors can be connected to the measuring system. The viscosity can be configured

as a medium constant value.

Sender/receiver

unit, slave

(probe B)

v = velocity of gas in m/s

L = measuring path in m

= angle of inclination in °

t

AB

= sound transit time

in flow direction

t

BA

= sound transit time

against flow direction

Sender/

receiver unit,

master

(probe A)

t

BA

v

t

AB

L

Higher level

control system (Interface Unit)

NOTICE:

The correct evaluation of the Reynolds number is decisive for the determination

of the correct calibration function. The Reynolds number must be determined

with an accuracy of 20% in order to achieve the device accuracy offered by

SICK.

Re

v D

-------------------

=

v = Speed of sensor

D = Inner pipe diameter

ρ = Density of medium

η = Viscosity of medium

Loading...

Loading...