24 FLOWSIC100 Flare-XT · Operating Instructions · 8023761/V 1-0/2020-10 · © SICK Engineering GmbH

Project planning

4.2.2

Additional requirements for optional spool piece

4.2.3 Installation location for external pressure and temperature transmitters (option)

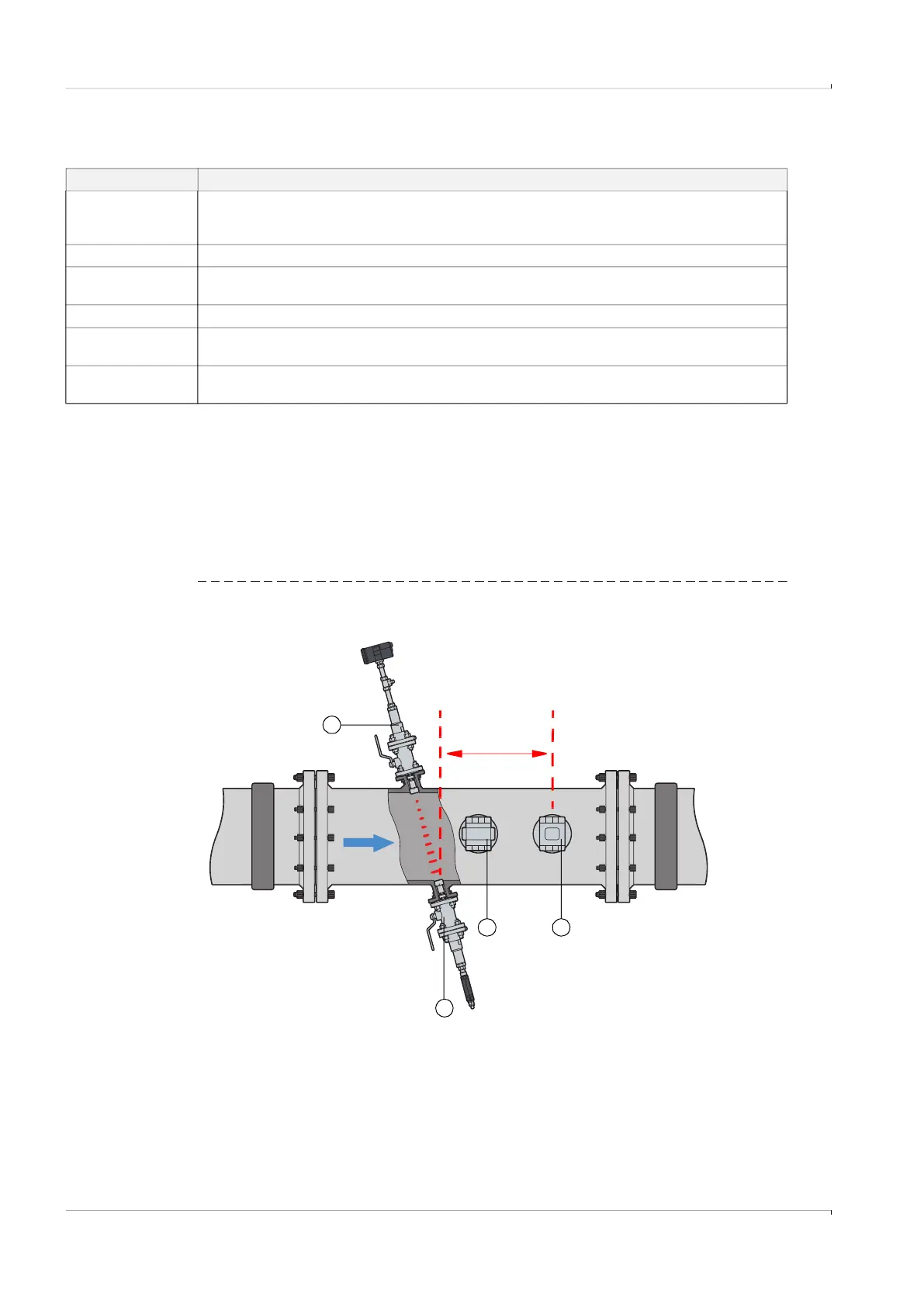

Pressure tappings and thermowells for external transmitters have to be installed in the

following way:

● Pressure tapping connection: Directly at the measuring point, centrally above the

measuring path, on the top of the pipeline

● Thermowell: Outlet section with distance 5 D

T

( = 5 * thermowell diameter), measured

from the middle of the measuring path, on the top of the pipeline

Fig. 5 Installation location

Criteria Requirements

Pipeline design

● Same nominal size of adjacent pipes and spool piece.

● Differences of internal diameters of inlet pipe and spool piece < 1%.

● No welding beads and burs on the flanges of the inlet pipe

Gas flow Free from any foreign material, dust and liquids. Otherwise, filters and traps shall be used.

Seals between spool

piece and pipeline

Must not protrude into the pipeline. Any protrusion into the flowing gas stream may change the flow

profile and thus may adversely affect measuring accuracy.

Pressure sensor Pressure tapping over the measuring path

Temperature sensor

Spool piece with standard installation length with integrated pressure tapping, temperature sensor

5 D

T

( = 5 * diameter of the thermowell) in the outflow area

Fastening and sealing

material

Bolts, nuts and flange seals used must be suitable for the operational conditions and comply with legal

regulations and relevant standards.

5 D

T

*

4

3

1

* D

T

=Diameter of thermowell

2

Top view

1 Sender/receiver unit FLSE-XT Master

2 Pressure sensor

3 Temperature sensor

4 Sender/receiver unit FLSE-XT Slave

Loading...

Loading...