128 FLOWSIC100 Flare-XT · Operating Instructions · 8023761/V 1-0/2020-10 · © SICK Engineering GmbH

Commissioning FLOWSIC100 Flare-XT

7.5.6

I/O configuration

In the I/O configuration step, the parameters can be set for the interfaces available in

accordance with the ordered configuration. Depending on the configuration, several

modules of one type may be available.

The designation Px behind the interface designation describes the position of the module,

for arrangement see

p. 110, §6.5.5.

7.5.6.1 Ethernet

The MAC address can be read out in this view.

▸

Enter IP address, network mask and gateway.

▸

When no gateway is used, enter “0.0.0.0” as gateway.

7.5.6.2 RS485/RS232

Define the communication settings for connected devices, e.g., for connected gas

chromatographs.

Table 14 Selection options for connected devices

7.5.6.3

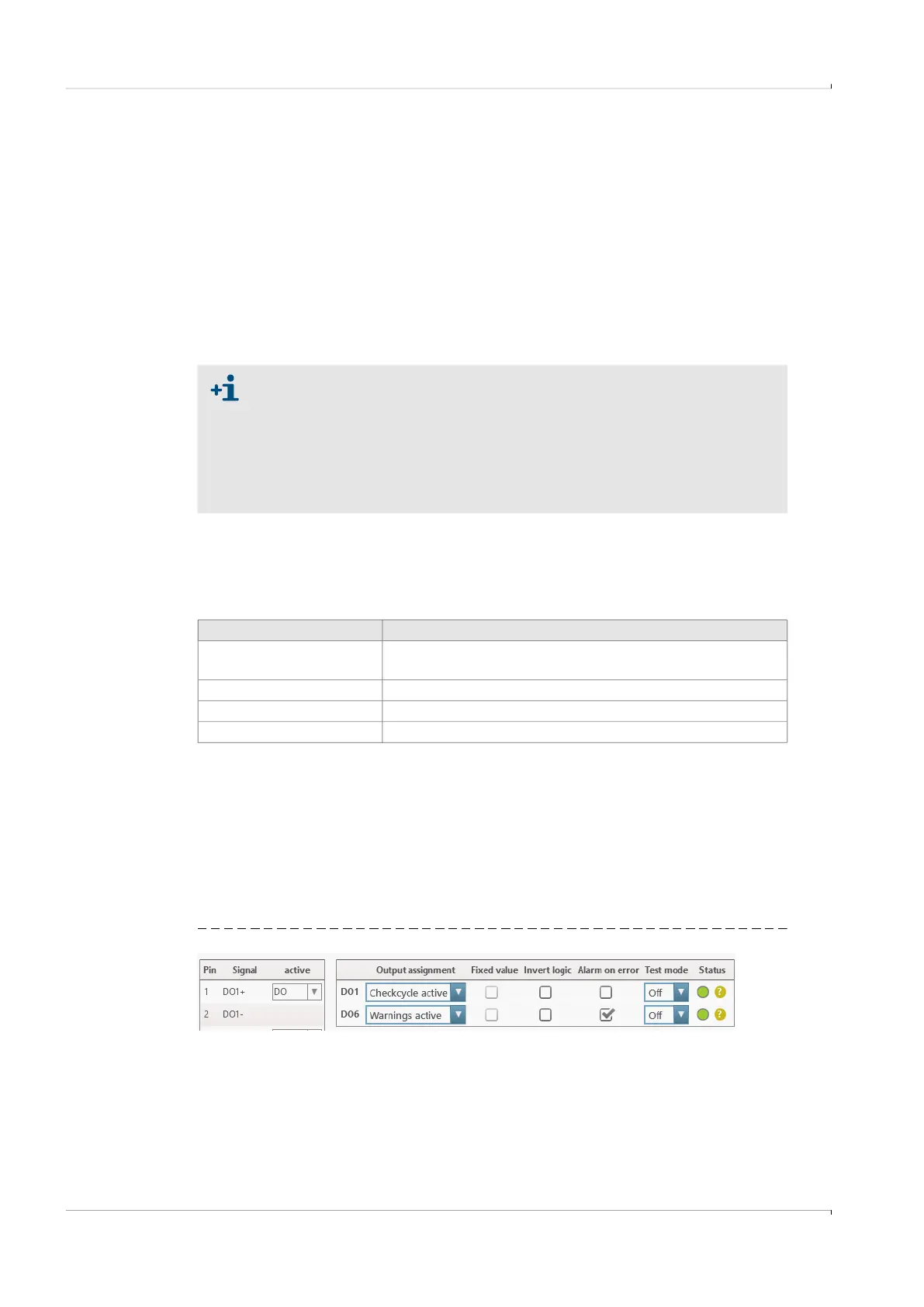

DI/DO (layout depending on the selected configuration)

Digital outputs DO1, DO2 and DO4 can be activated.

DO3 can be configured as status output or pulse output (PO1). The desired measured value

can be assigned to the pulse outputs. The desired function can be assigned to the digital

output in the “Function” menus.

DO5 and DO6 can be configured as digital inputs DI1 and DI2.

Example for the configuration of a digital output:

Fig. 79 DO1 (example)

Factory settings:

● Ethernet port 1:

– IP address: 192.168.1.100

– Network mask: 255.255.255.0

● Ethernet port 2:

– IP address: 192.168.2.100

– Network mask: 255.255.255.0

Selection Description

Flowgate Modbus Ser

Connection Service PC via RS485-USB Adapter Using

Flowgate over greater distances than with infrared adapter

Scada MODBUS Ser Connection Interface Unit to higher level control system

MCU-P compatible Interface Unit MODBUS Register mapping analog to MCUP

GC Connecting a standardized gas chromatograph

Loading...

Loading...