20 FLOWSIC200 · Operating Instructions · 8013271/1CJ9/V 2-0/2022-01 · © SICK Engineering GmbH

Product description

2.2.3 MCU control unit

The control unit has the following functions:

Control of data transfer and processing the data from the sender/receiver units

connected via RS485 interface

Signal output via analog output (measured value) and relay outputs (device status)

Signal input via analog and digital inputs

Voltage supply for the connected sender/receiver units

Communication with host control systems via optional modules

System and device parameters can be set easily and conveniently via a USB interface

using a laptop and the user-friendly SOPAS ET operating software. The parameters are

stored reliably even in the case of a power failure.

The control unit is usually installed in a stainless steel housing.

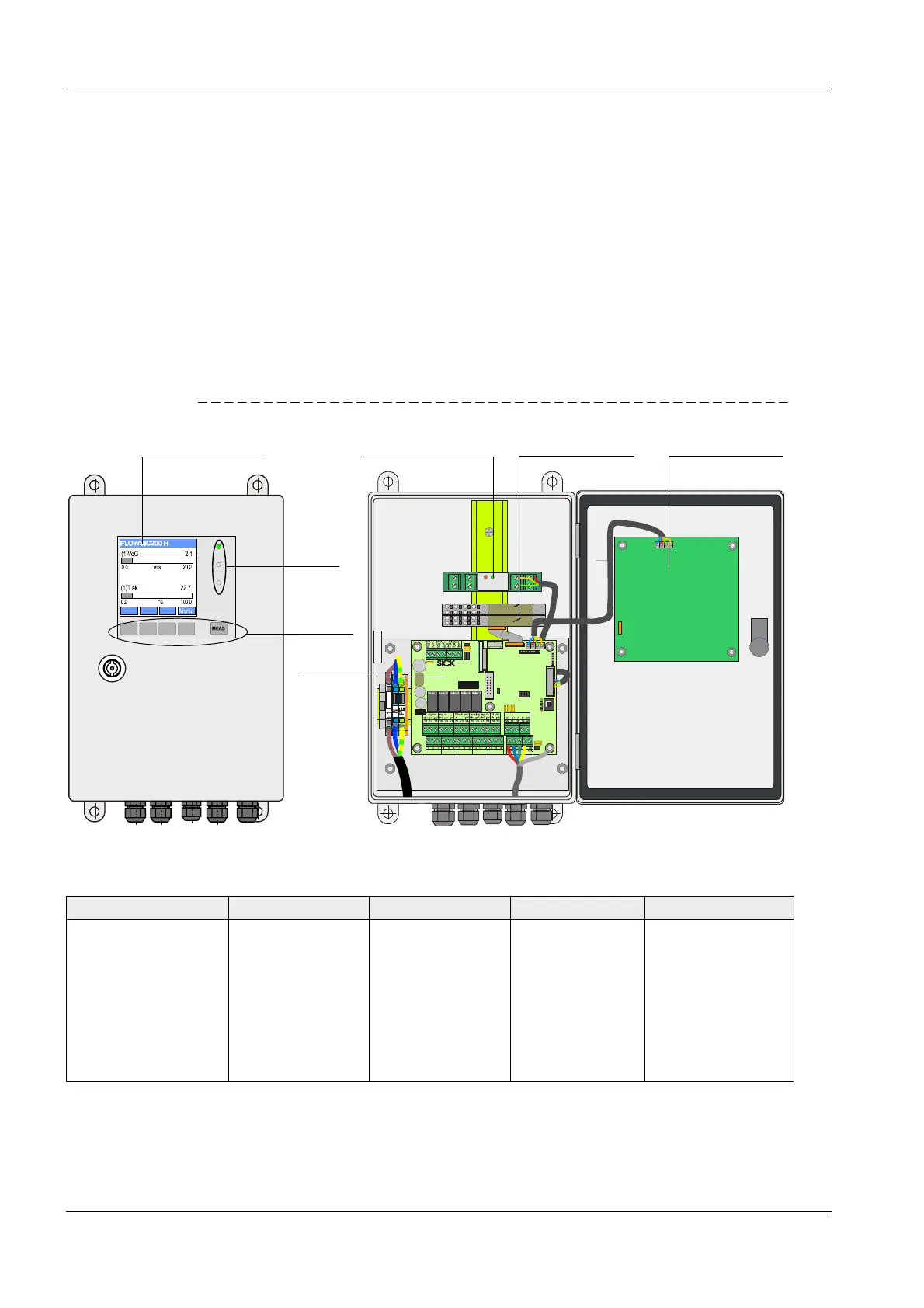

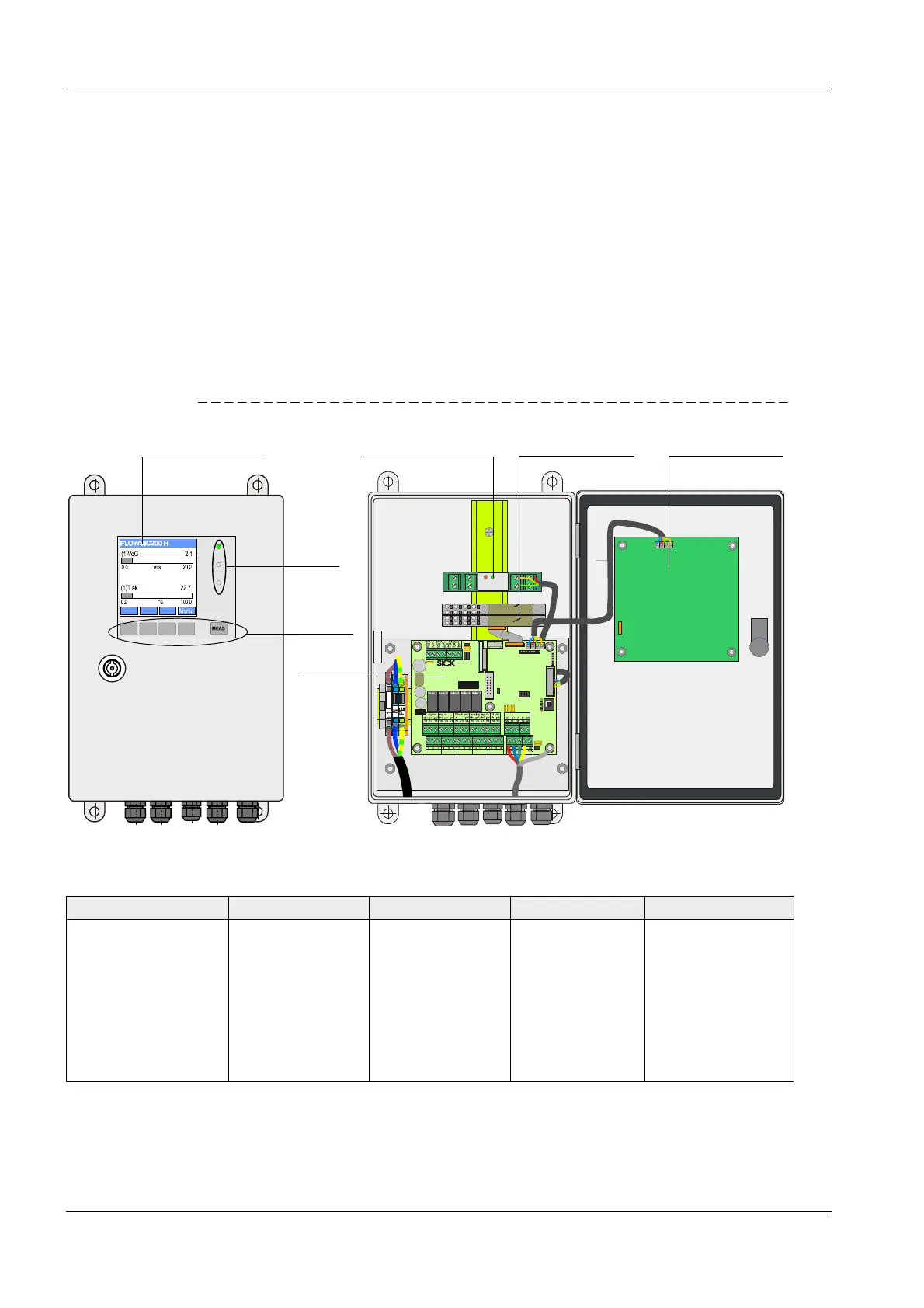

Fig. 7 MCU control unit options

Standard interfaces

DISPLAYMODUL

relay 3 relay 4 relay 5

BUS - S/E unit 1

BUS

Ter m

Ter m

BUS - S/E unit 2

relay 1

relay 2

com nc. no. com nc. no. com nc. no. com nc. no. com nc. no.

Reset

LED

Control

buttons

Processor

board

Option Display module Option Interface module Options I/O module Option Display module

Analog output Analog inputs Relay outputs Digital inputs Communication

1 output 0/2/4...22 mA

(electrically isolated,

active); for selectable

output of measured

variables:

–Velocity

–Air temperature

Resolution 0.01 mA

2 inputs 0 ... 20 mA

(Standard; without

electric isolation)

Resolution 0.01 mA

5 NC contacts (48 V,

1 A) to output status

signals:

– Operation/

malfunction

– Maintenance

– Check cycle

– Maintenance

request

– Limit value/direction

2 inputs to connect

potential-free

contacts for a

maintenance switch or

triggering a check

cycle

– USB 1.1 and RS232

(on terminals) for

measured value

inquiries, setting

parameters and

software updates

– RS485 for sensor

connection

Loading...

Loading...