Commissioning and parameterization

FLOWSIC200 · Operating Instructions · 8013271/1CJ9/V2-0/2022-01 · © SICK Engineering GmbH 75

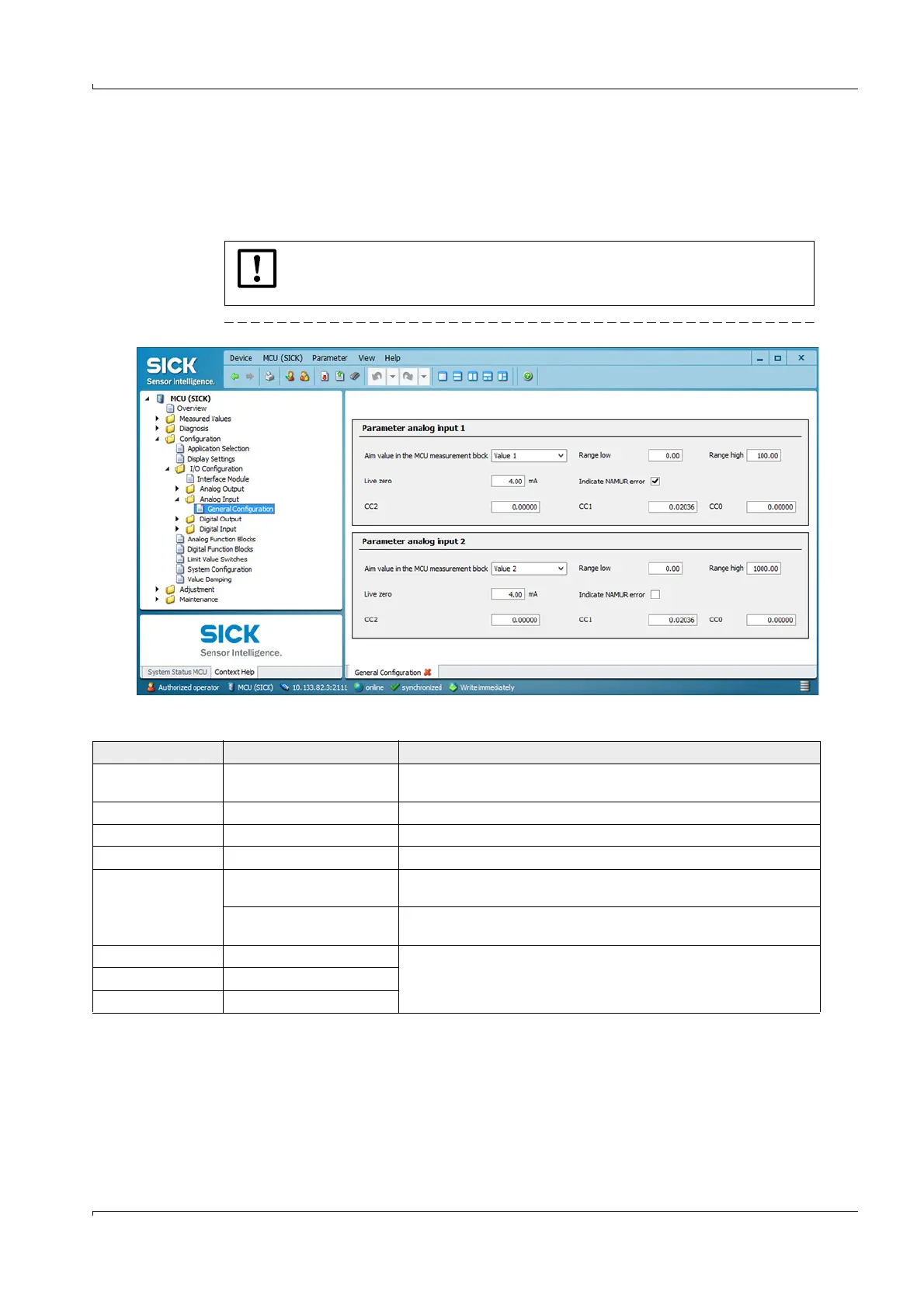

4.2.7 Configuring the analog inputs

In directory “Configuration / I/O Configuration / Analog Input / General Configuration”, the

standard analog inputs can be assigned to any measured values to be standardized in the

“Parameter analog input 1” and ”Parameter analog input 2” groups, and the respective

measuring range can be defined.

Fig. 62 Directory “Configuration / I/O Configuration / Analog Output / Analog Input“(example)

NOTICE:

Correction factors CC2, CC1 and CC0 are preset at the factory and may only be

changed by SICK Service.

Field Parameter

Remark

Aim value in the MCU

measurement block

Measured value 1 to 8 Variable to be assigned to the selected analog input

Range low Lower measuring range limit Physical value at live zero

Range high Upper measuring range limit Physical value at maximum current

Live zero Zero point value > 0 mA) Specification of the mA value for measurement range start

Indicate NAMUR error Inactive No error is reported for underflow or overflow of the set current range

(LZ to 20 mA).

Active An error is reported for underflow or overflow of the set current range

(LZ to 20 mA).

CC2 Square correction factor Correction factors for calibrating the input size (factory preset)

Modification only by SICK Service!

CC1 Linear correction factor

CC0 Absolute correction factor

Loading...

Loading...