32 FLOWSIC200 · Operating Instructions · 8013271/1CJ9/V 2-0/2022-01 · © SICK Engineering GmbH

Assembly and installation

3.1

Project planning

3.1.1 Planning steps

Plan the following before starting assembly and installation work:

Determine measuring location(s).

Select system components according to

p. 18, §2.2 meeting the conditions of use and

customer requirements.

Define installation locations for sender/receiver units, MCU and junction boxes.

Plan power supply.

3.1.2 Requirements for the installation location for the sender/receiver units

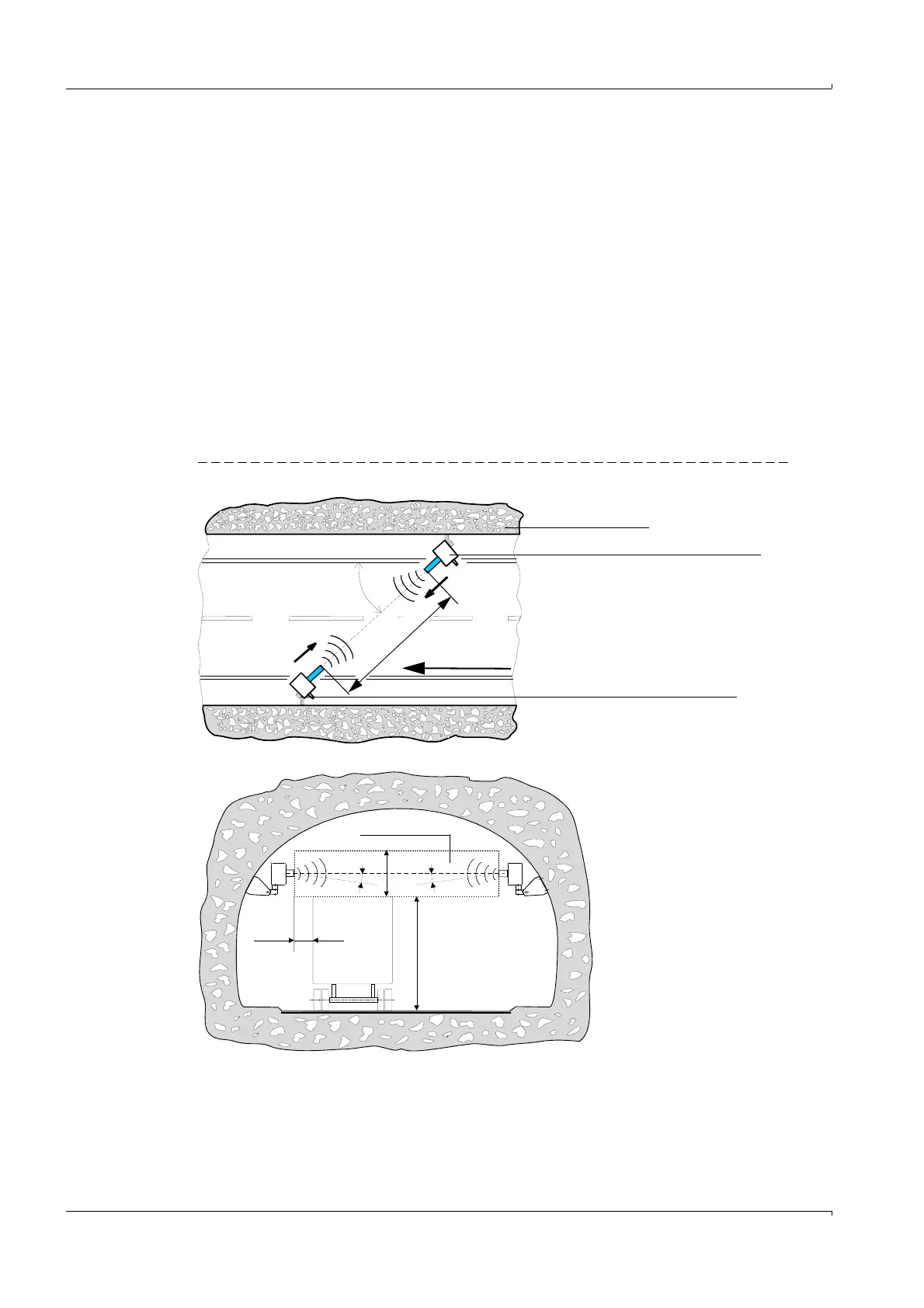

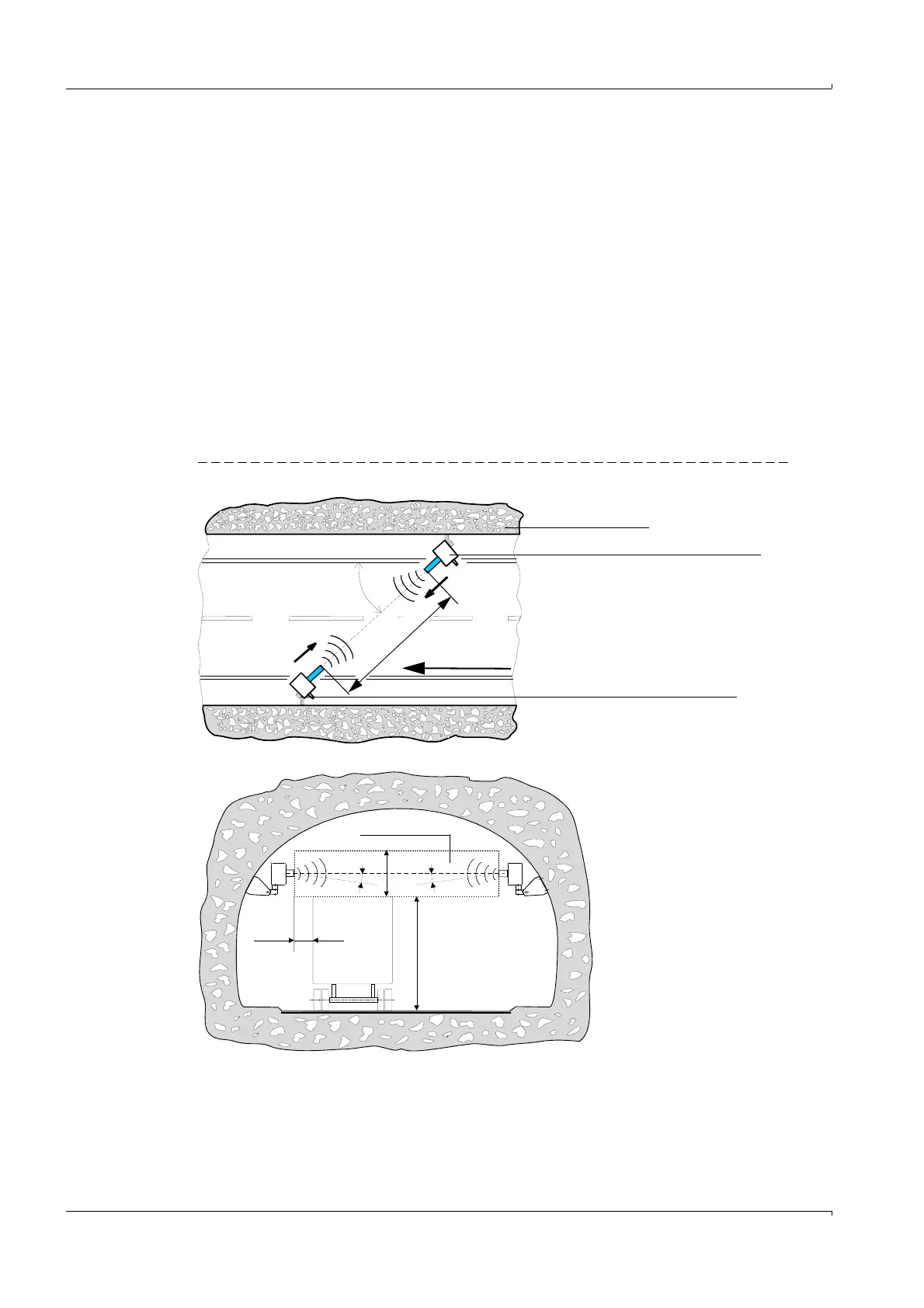

The master and slave sender/receiver units must be installed on opposite tunnel walls at a

sufficient height above the road surface, offset to the side (

Fig. 12). The angle between

the measuring axis and tunnel axis should not be significantly greater than 60° (minimum

value 45°).

Fig. 12 Installation location for sender/receiver units

45 ... 60°

M

e

a

s

u

r

i

n

g

d

i

s

t

a

n

c

e

Max. permissible

vehicle height

Max. 5 °

> 0.5 m

> 2 m

Clearance

Tunnel wall

Sender/receiver unit, Master

Sender/receiver unit, Slave

Flow direction

Loading...

Loading...