Installation

FLOWSIC500 · Operating Instructions · 8025733/1GMJ/V4-2/2022-07 · © SICK Engineering GmbH 45

Subject to change without notice

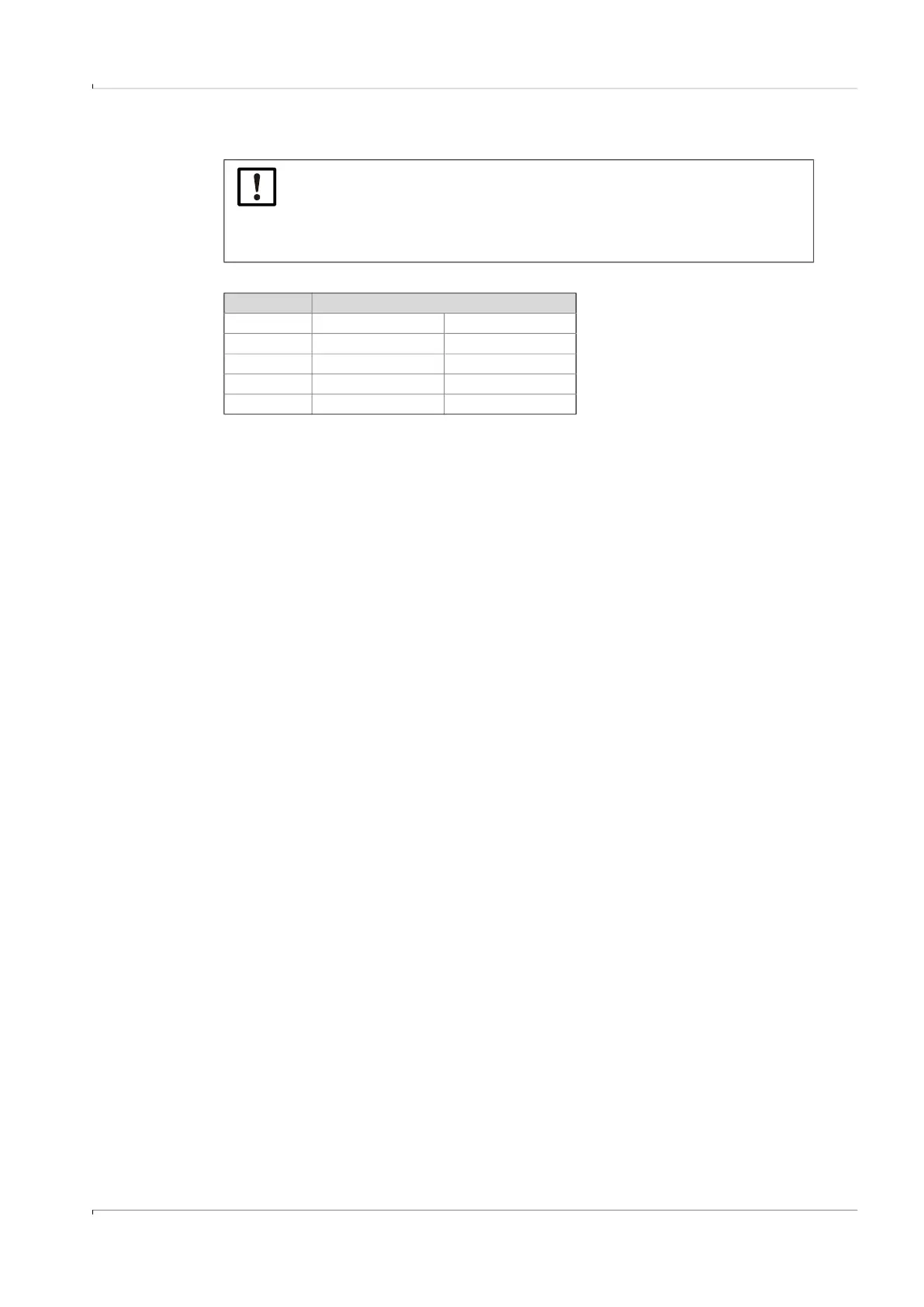

3.3.3.2 Pipeline torque

Table 13 Pipeline torque

3.3.3.3

Installation in pipeline

1 Select suitable bolts.

Recommended bolts → Table 8.

2 Use the hoisting equipment to position the FLOWSIC500 in the desired location in the

pipeline.

Lay the pipelines without tension to the device to be installed!

3 Insert and align the gaskets.

4 Apply lubricant to the bolts.

5 First screw the bolts by hand into the adapter to the stop.

– Screw in the bolts according to DIN835 with the shorter thread end.

– The bolts according to ASME B18.31.2 can be screwed in with any end.

6 Check the thread length in the adapter is fully utilized.

7 Then install the washers and nuts, and tighten them by hand.

8 Check whether the thread length of the nut is fully utilized.

If necessary, use a different bolt length.

9 Check correct positioning of flange gaskets.

10 Tighten nuts evenly and crosswise in small steps until the specified tightening torque is

reached (→ Table 8).

Make sure the flange sits free of tension.

11 Slowly increase the pressure in the pipeline.

Gradient: Max. 3 bar/min (45 psi/min)

12 Carry out a leak tightness check on the pipeline (in accordance with the pipeline

operating company's specifications).

NOTICE:

If the FLOWSIC500 is installed so that the gas flow meter projects sideways

from the pipeline, the gas flow meter weight creates a torque on the pipeline.

▸

Make sure the pipeline is capable of holding the gas flow meter → p. 45,

Table 13.

Meter size Torque

[Nm] [lbf ft]

DN50/2" 6 5

DN80/3" 16 12

DN100/4" 31 23

DN150/6" 31 23

Loading...

Loading...