Scale parameters and functions of the belt scale

8.18 DR 18 Control digital output

SIWAREX WP241

118 Manual, 04/2014, A5E33713528A

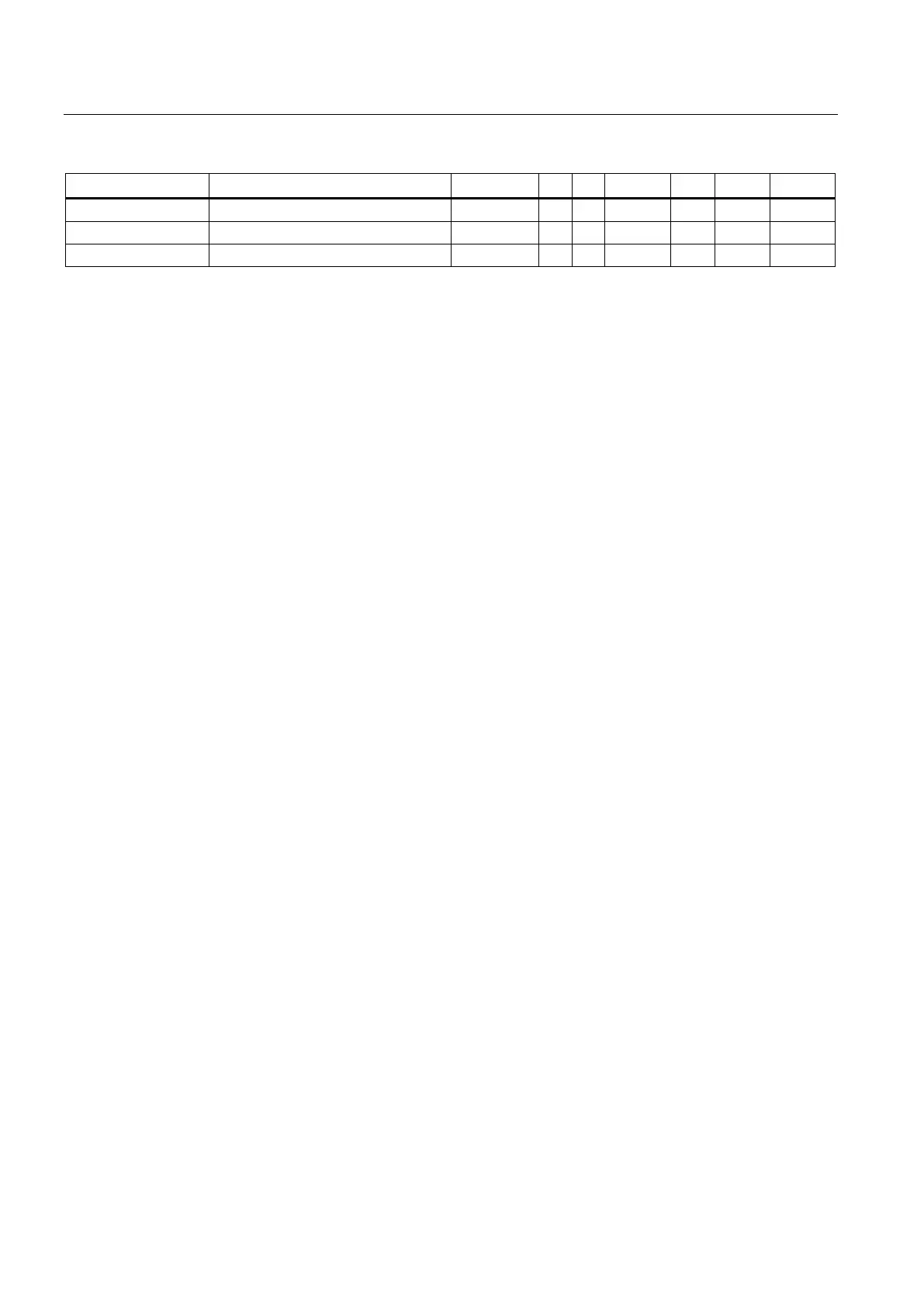

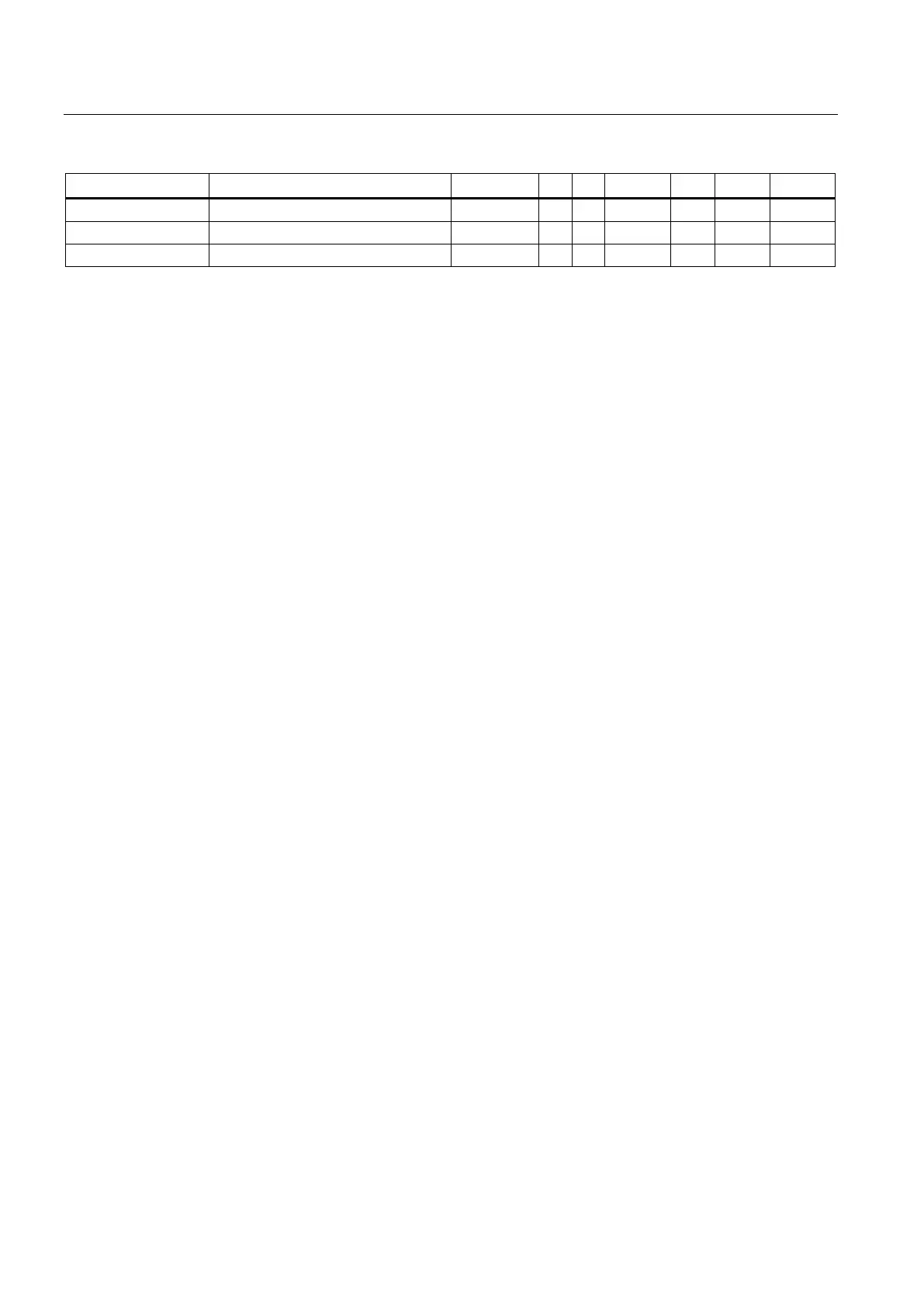

Definition for digital output DQ.0, 1, 2, 3

Digital outputs 0 to 3 can be controlled using data record 18 with this parameter. This

function can be used for commissioning purposes, for example.

Loading...

Loading...