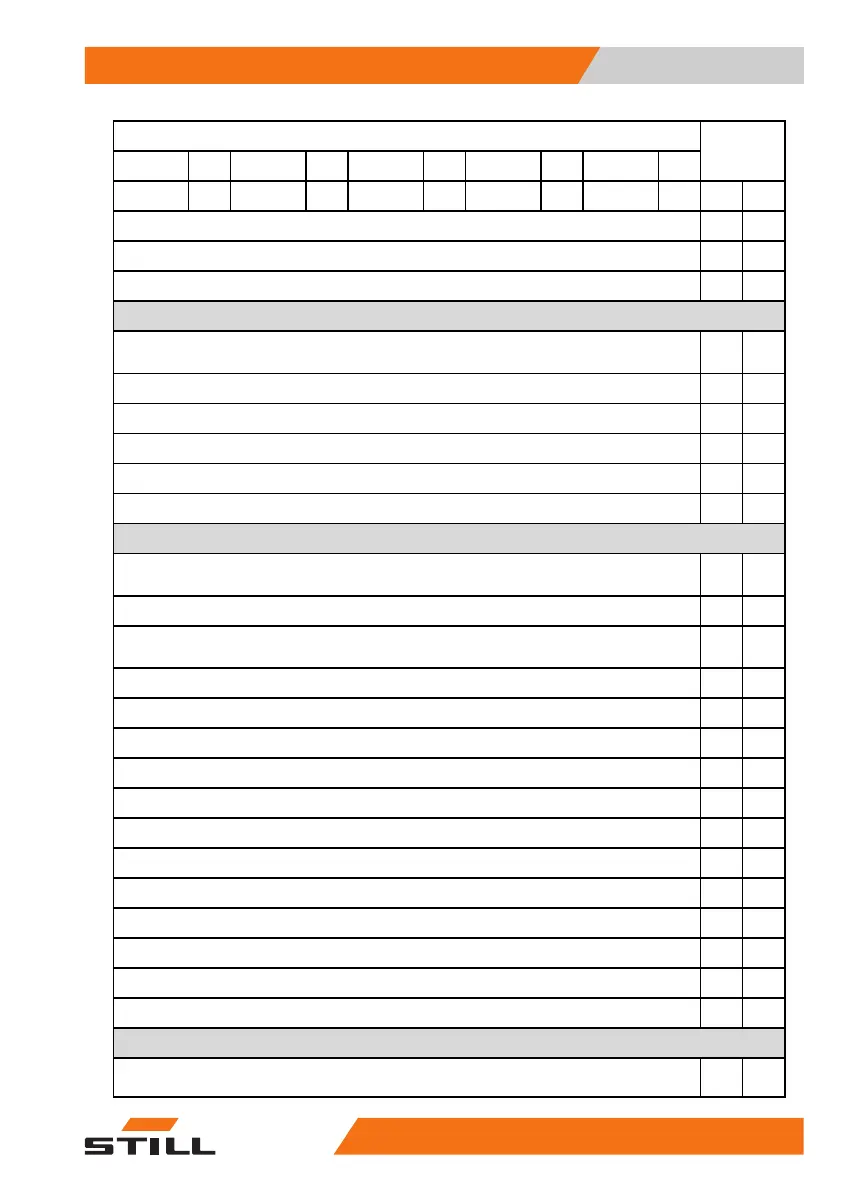

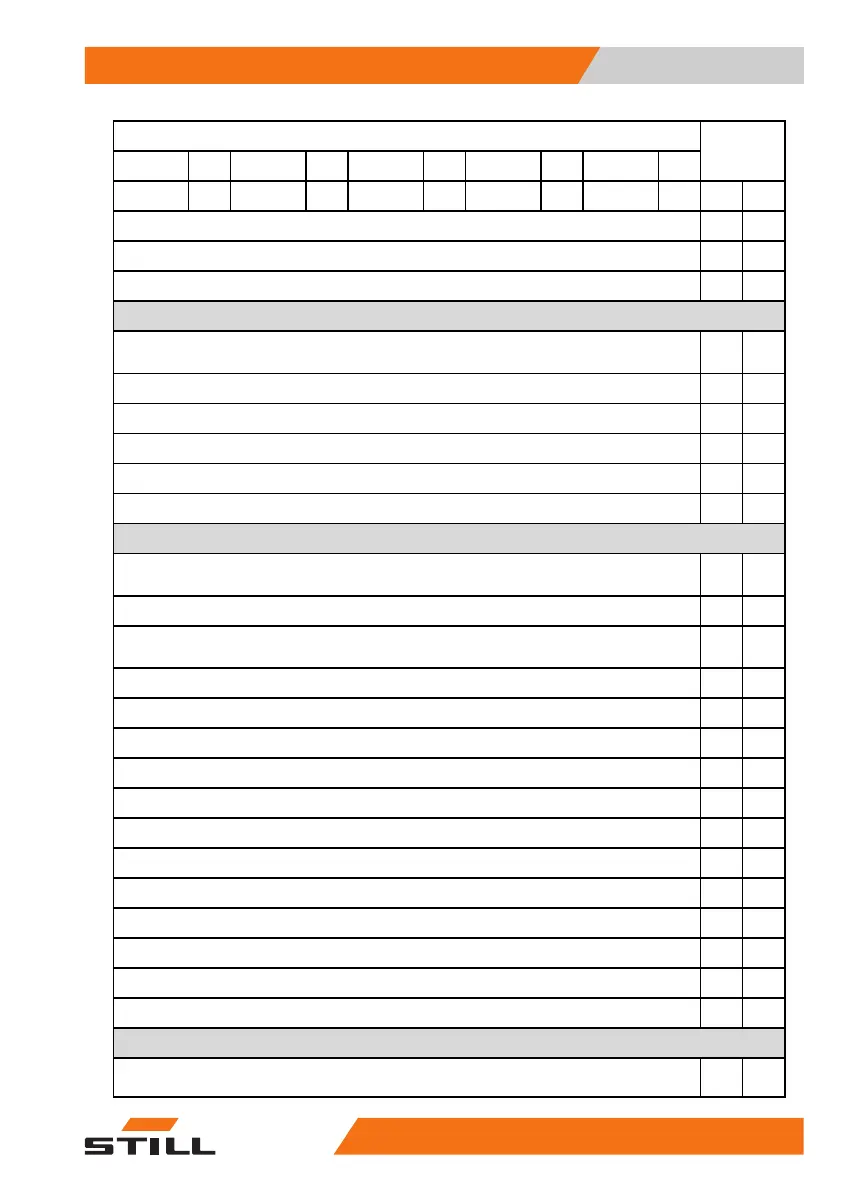

Maintenance 6

General maintenance information

At operating hours

1000 2000 4000 5000 7000

Carried

out

8000 10000 11000 13000 14000

Measure the battery voltage u

nder load

Perform insulation testing

Measure the tray for short circuits

Hydraulic system

Check the condition of the hydraulic system and check for damage, correct function

and leak tightness

Check the hydraulic pu

mp for leak tightness

Check the hydraulic

oil level

Check the oil filter

(and replace if dirty)

Test the oil tank fo

r leak tightness

Clean the breathe

r filter and replace if necessary

Lift mast

Check the mast mounting for damage and check the tightening torques. For mast

traversing, check and lubricate the sliding faces

Check the mast profiles for damage and wear. Lubricate the mast profiles

Check the load chains for damage and wear. Adjust and lubricate the load chains.

Replace the main lift chains after 5000 operating hours (recommendation)

Check the lift cylinders and connections for damage and leaks

Check the guide pulleys for damage and wear

Check the mast rollers and chain rollers for damage and wear

Check the tilt cylinders and connections for damage and leaks

Check the joints of the tilt attachment for play and ease of movement

Check the reach cylinder and connections for damage and leaks

Check the joints of the reach cylinder for play and ease of movement, and lubricate

Check the fork carriage for damage and wear

Check the fork height setting and adjust the chain length if necessary

Check the fork arm interlock for damage and correct function

Check the fork arms for wear and deformation

Check that there is a safety screw on the fork carriage or on the attachment

Sp

ecial equipment

Check the heating system for damage; observe the manufacturer’s maintenance

instructions

50

988078001 [EN] 233

Loading...

Loading...