Maintenance 6

General maintenance information

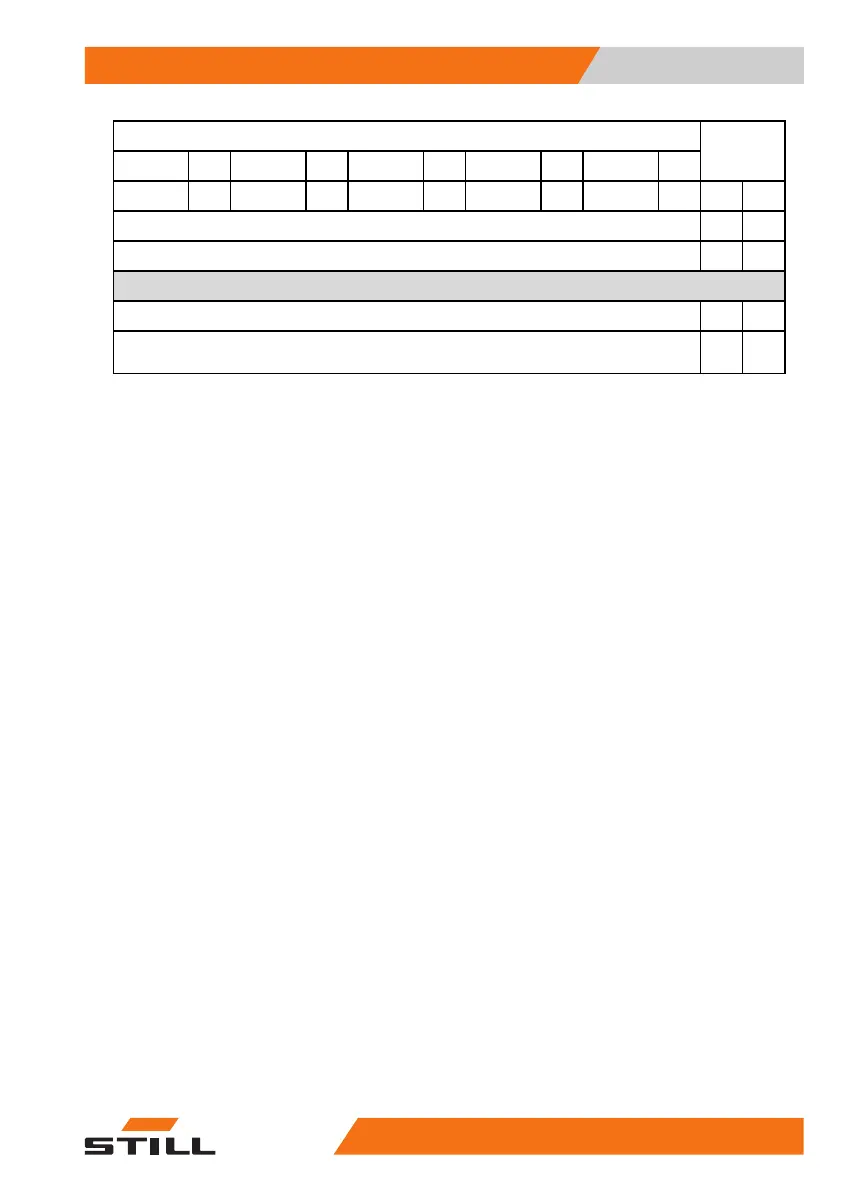

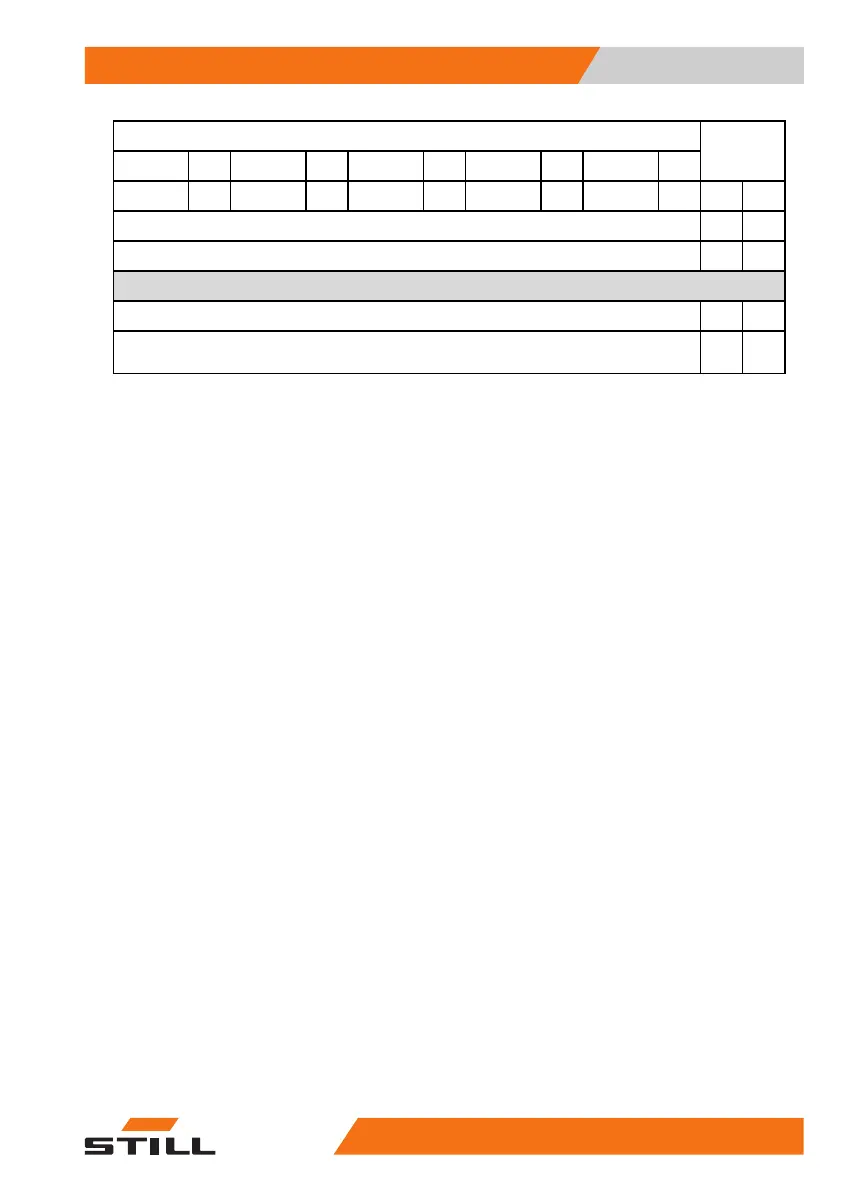

At operating hours

500 1000 1500 2000 2500

Carried

out

3000 3500 4000 4500

Perform a visual inspection of the fork arms

Check the ease of movement of the limit switches

Lubricating

Lubricate using approve

d lubricants in accordance with the lubrication plan

In addition, lubricate the lubricating nipple for the door hinges and the door closing

mechanism every six weeks

Ordering spare part

s and wearing

parts

Spare parts are pro

vided by our spare parts

service departmen

t. The information required

for ordering parts

can be found in the spare

parts list.

Only use spare parts as per the manufac-

turer’s instructions. The use of unapproved

spare parts can result in an increased risk of

accidents due to insufficient quality or incor-

rect assignment. Anyone using unapproved

spare parts shall assume unlimited liability in

the event of damage or harm.

Quality and quantity of the required

operating materials

Only the operating materials specified in the

maintenance data table may be used.

– The required consumables and lubricants

can be found in the maintenance data table.

Oil and greas

e types of a different quality

must not be mi

xed. This negatively affects

the lubricit

y. If a change between different

manufacture

rs cannot be avoided, drain the

old oil thoro

ughly.

Before carrying out lubricating work, filter

changes or any work on the hydraulic system,

carefully clean the area around the part

involved.

50

988078001 [EN] 239

Loading...

Loading...