The information contained in this document is confidential, and only for the information of the intended recipient and may not be published or redistributed without the prior written consent of Summa NV.

Summa nv Tel +32 59 27 00 11 Fax +32 59 27 00 63 Email support@summa.com Website www.summa.com Page 37 of 76

• In case an inkjet printer was used, let the media dry and cool down before putting it in the

cutter, as it will change dimension while cutting due to cooling and drying. This may result in

a clear track on one side, and a diffuse track on the other side.

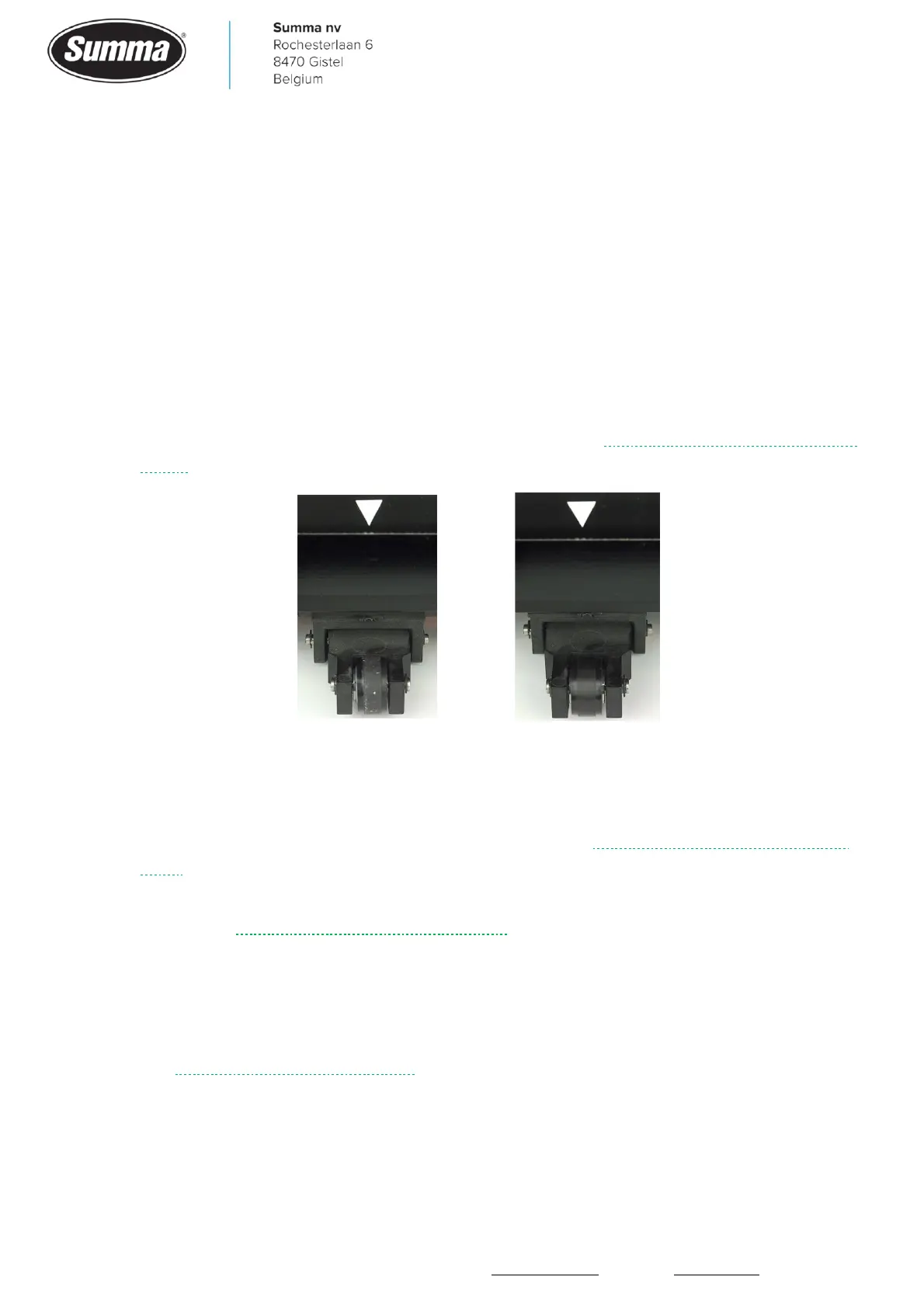

• The middle pinch roller has to be above a yellow grit roller when set down. The left and the

right pinch roller always need to be set above a yellow grit roller on the edge of the media. The

outermost pinch rollers are used to feed the media, while the middle pinch rollers are only

used to keep the media flat.

• The pinch roller pressure should be equal left and right. Do not use a reduced pinch roller

pressure unless very fragile media is used.

• The pinch rollers may be worn. Due to this the hardness of the pinch roller surface changed.

Or the black part may have come loose from the metal core. Replace the two outermost pinch

rollers (395-401).

• One of the outermost pinch roller blocks may be defective. Replace the defective pinch roller

block.

• The machine may cut too close to the right side track made by the pinch roller pressure on the

drive drum. Adjust the right side cutting margin. This will affects cut only jobs. Should not affect

print & cut jobs.

• The pressure between the leftmost and rightmost pinch roller may be different: check the

pinch roller pressure using a scale and paper and check with what force the pinch roller has to

be lifted to be able to move the sheet from under the pinch roller (should be between 7 and 8

kg). Adjust the pinch roller pressure if needed.

Loading...

Loading...