S CLASS™ cutter User’s Manual

Detailed Operation 4-9

4.3.1.4 OPOS

The OPOS settings are explained in detail in section 3, except for the Alignment mode,

monitor and OPOS paneling.

Alignment:

There are three additional alignment methods available on all S CLASS™ cutters:

X-Alignment, XY-Alignment and XY-Adjustment. These alignment methods can be used if

the combination of marker color – media color cannot be read by the OPOS sensor.

These alignment methods require that the user manually register markers using the cutter’s

keypad. Most cutting software can automatically put these markers around the printed

graphic.

X-Alignment compensates for errors in media alignment, by rotating the graphic’s contour.

This alignment method requires that the user specify the Origin and one point along the X-

Axis. X-Alignment is the simplest alignment method.

XY-Alignment compensates for errors in graphic rotation and skew. Skew errors occur when

the graphic’s X and Y Axes are not perpendicular. This alignment method requires that the

Origin and one point along both the X and Y Axes be specified.

XY-Adjustment compensates for errors in graphic rotation, skew, and scale. Scale errors

occur when the graphic’s printed size is different from the graphic’s original size as created

in the imaging software. X-Distance and Y-Distance parameters are required. These

parameters define the distance between the Origin and X-Axis point, and between the

Origin and Y-Axis point. XY-Adjustment is the most accurate manual alignment method.

Press the button, then use or to change the alignment method.

Press

to confirm or to cancel.

Default alignment method is OPOS.

OPOS paneling:

With this option, the markers can be read in panels. The OPOS sensor will read markers

according to panel size, instead off loading them all be.

OPOS Panels can be set to OFF or ON. When set to ON, then the sensor will load only 2

markers in X-direction when loading OPOS. Other markers will be read when unrolling

media. Must be used with internal or software paneling.

OPOS XY is not supported when using paneled OPOS.

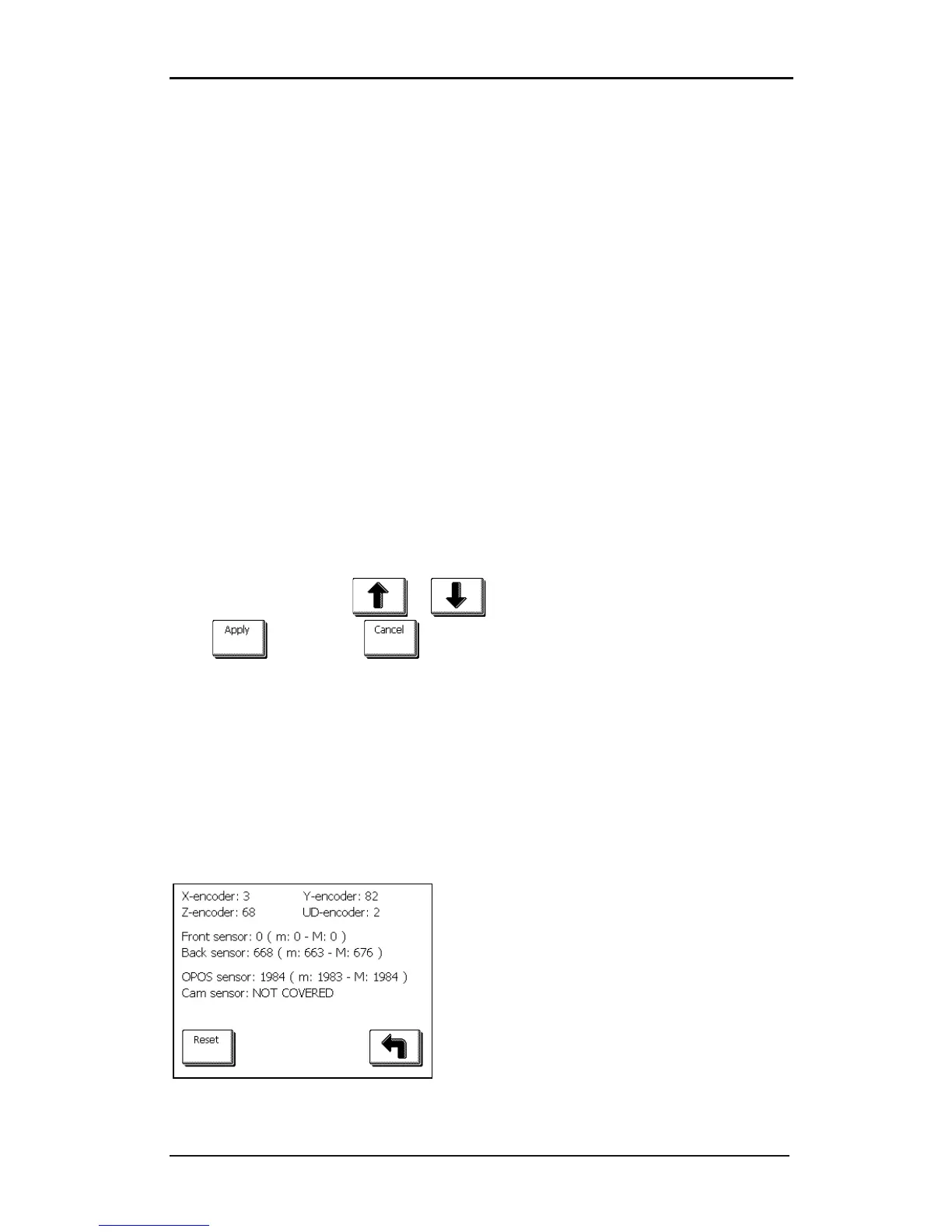

Monitor:

This option shows the read-out of all the sensors in

the cutter. X and Y encoder are for the position of

the X and Y motor. Z encoder is for the motor on a

T head. UD- encoder is the encoder inside the

head measuring the height. The front and back

sensors are the media sensors The OPOS sensor

shows the reflection of the OPOS sensor. Cam

sensor is the sensor to determine the position of

the pinch rollers. The values can be used to report

a problem to a certified service technician.

Loading...

Loading...