ELECTRICAL SYSTEM

10H-22

ENGINE OIL PRESSURE SWITCH

TEST (SW7)

The oil pressure switch is pressure sensitive and acts

as a ground for the oil pressure light on the control

panel. When the engine is not running, a lack of oil

pressure creates a ground and illuminates the oil light

(L2). When the engine starts and builds pressure, the

sender opens and the light (L2) goes out.

Test the oil pressure sender as follows:

1. Shut down the engine and remove the ignition

key. Allow the engine to cool completely.

2. Remove the wiring harness connector from the

end of the oil pressure sender.

3. Set the multimeter to the continuity scale.

4. Place one test lead in the end of the sender and

the other test lead on the base of the sender

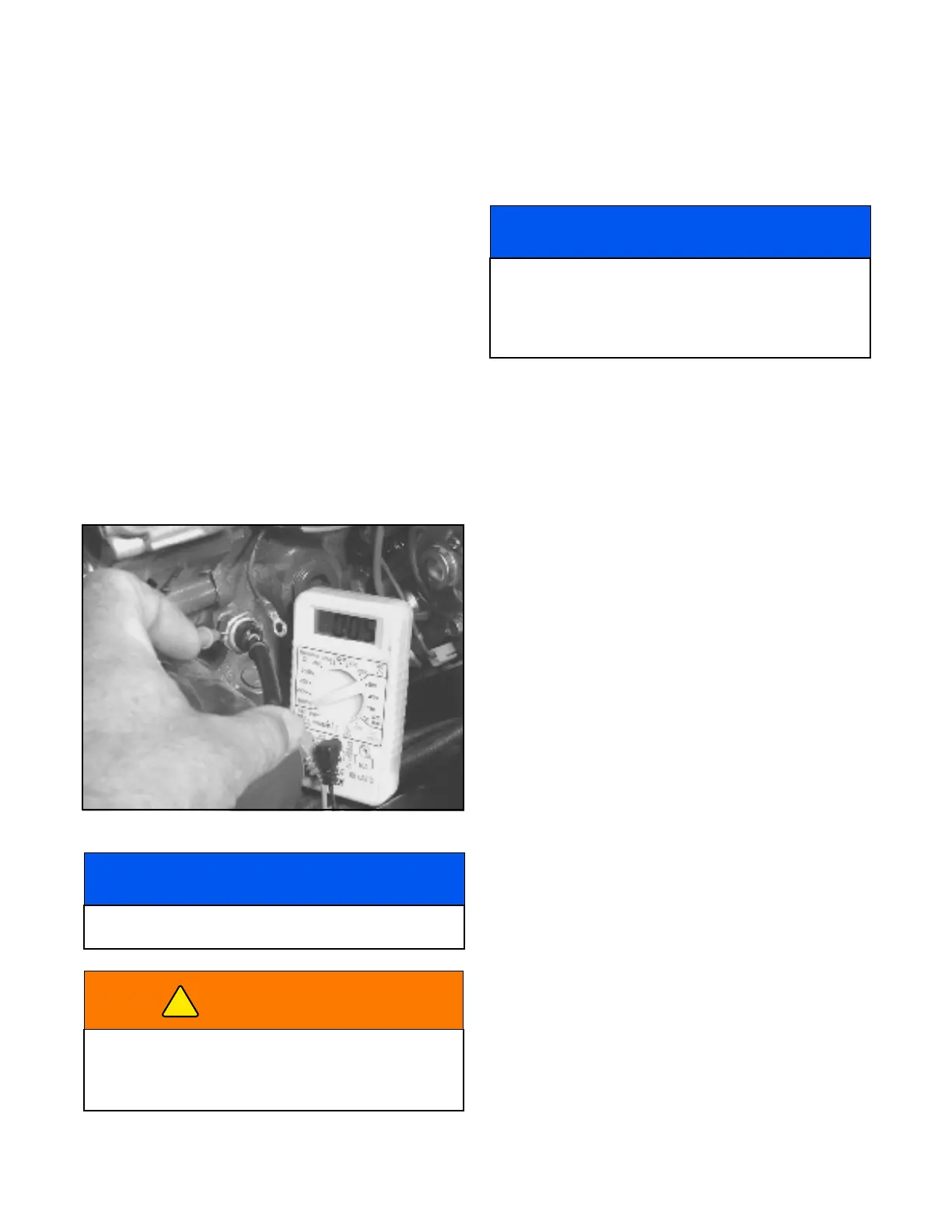

(Figure 10H-3).

Figure 10H-3. Oil Pressure Sender

5. Start the engine and perform the continuity test

again.

Continuity should not be available between the

sender end and the base with the engine running.

FUEL SENDER TEST (R3)

The fuel sender is a rheostat mounted underneath the

seat on the fuel tank. The fuel sender monitors the fuel

level and controls the fuel gauge. The fuel sender

resistance range is 33 (full) to 240 (empty).

Test the fuel sender as follows:

1. Shut down the engine and remove the ignition

key.

2. Pivot the seat and seat platform to the full upward

position.

3. Set the multimeter to the continuity scale.

4. Place one test lead on the fuel sender ground wire

and one test lead on a good frame ground.

Continuity should be available. If continuity is not

available, check for proper ground at the gauge.

5. Set the multimeter to the 2K scale.

6. Remove the wires from the sender. Place one test

lead on the fuel sender ground and one test lead

on the fuel sender stud.

Resistance should be available, depending on the

fuel level in the tank, between 33 (Ohms) and

240 (Ohms) If out of resistance range, replace

the sender. Connect wires to the sender.

7. Place the ignition switch in the RUN position.

8. While watching the fuel gauge, place a jumper

wire briefly between the fuel sender and fuel

sender ground.

The fuel gauge needle should move toward the

full mark when the jumper wire makes contact. If

the gauge does not respond, replace the gauge.

NOTICE

With the engine off, continuity should be available

between the end of the sender and the base.

WARNING

Beware of moving engine parts and do not become

entangled by loose clothing, jewelry, or hair. Serious

injury can occur if caught by moving engine compo-

nents.

NOTICE

If continuity is not available during testing, with the

engine off, the oil pressure sender may be faulty and

should be replaced. If continuity is available with the

engine running, perform an engine oil pressure test

with a gauge.

Loading...

Loading...