8-36 4252490-Rev A

CUTTING UNITS

8

Disassembly and Assembly

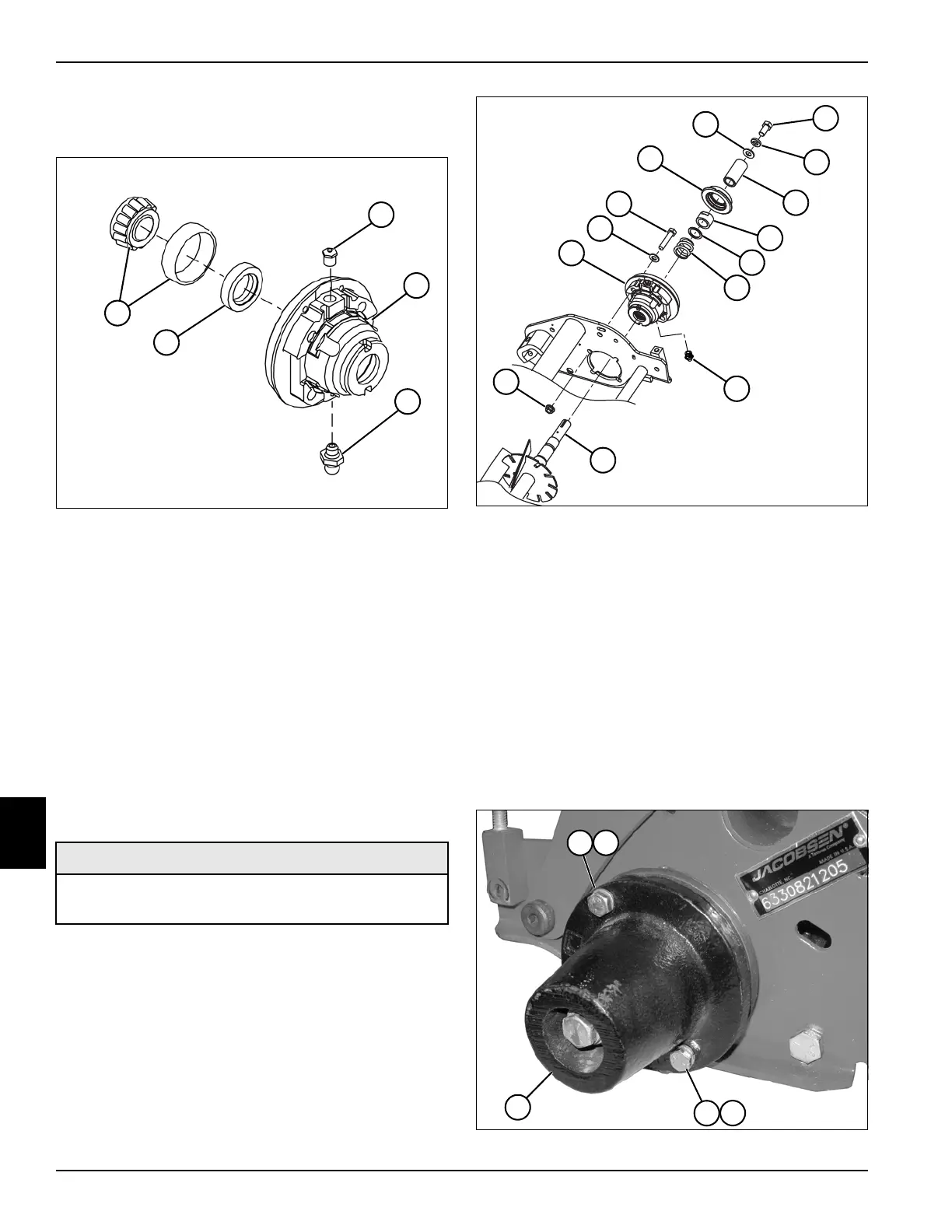

See Figure 8-40.

Figure 8-40

Assembly Notes

• Install new grease seal (2).

• Apply grease that meets or exceeds NLGI Grade 2

LB specifications to the lips of grease seal (2).

• Inspect bearing cup and cone (1) for wear or

damage. Replace as needed.

• Pack bearing (1) with grease that meets or exceeds

NLGI Grade 2 LB specifications before assembly.

Installation—Non-Drive Side

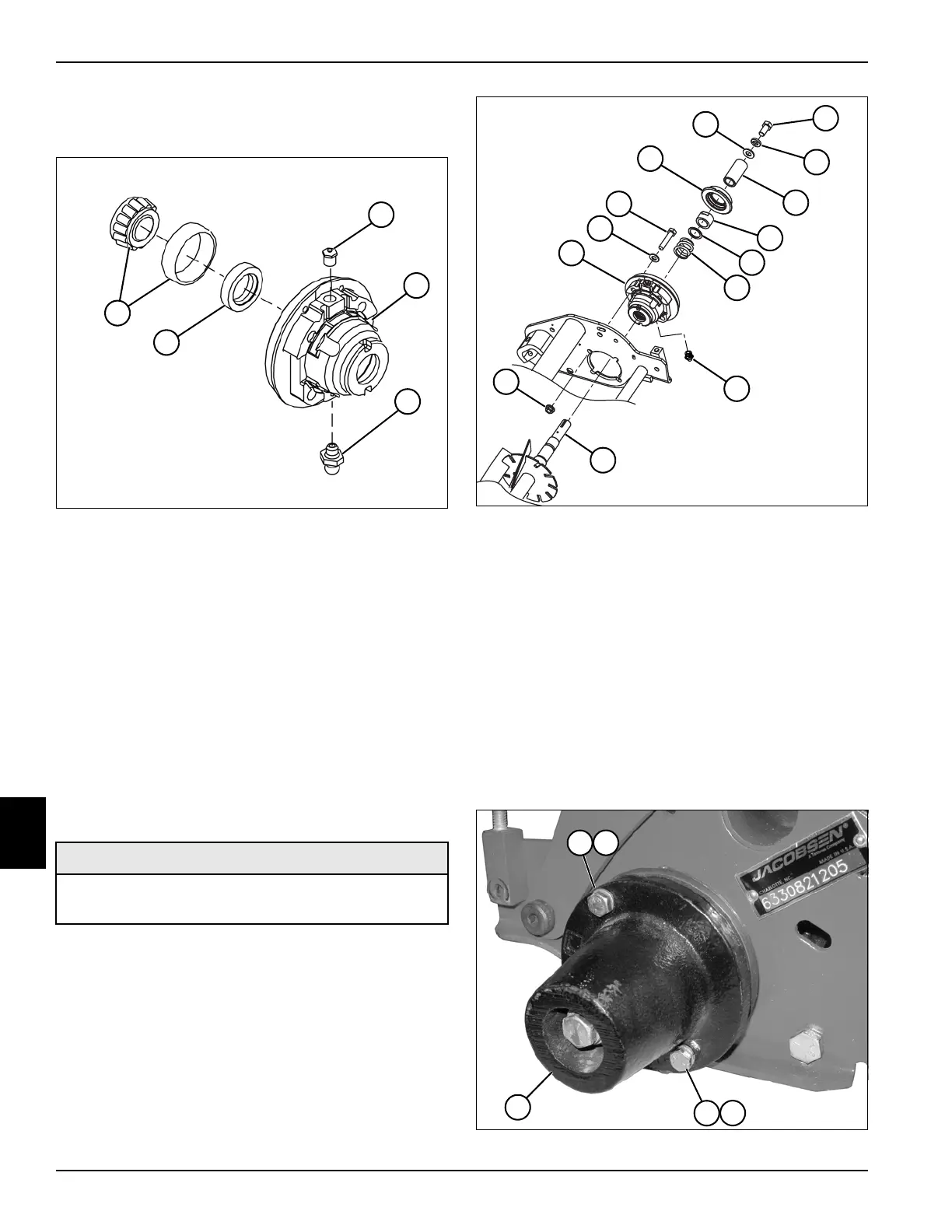

See Figures 8-41 and 8-42.

Figure 8-41

1. Install reel bearing housing assembly (8) using

bearing assembly tool (Jacobsen PN JAC5084).

2. Install seal (5) using mounting screws (6), washers

(7), and nuts (9).

3. Tighten mounting screws (6) to 18–22 lb-ft (24.4–

29.8 N·m).

4. Install grease fitting (11).

5. Install spring (12), washer (13), and nut (14).

6. Adjust reel bearing pre-load. (See “Reel Bearing

Pre-Load Adjustment” on page 8-19.)

7. Install spacer (15), flat washer (4), lock washer (16),

and screw (17).

Figure 8-42

1 Bearing Cup and Cone 4 Reel Bearing Housing

2 Grease Seal 5 Grease Fitting

3 Vent Fitting

Required Tools or Equipment

Bearing Assembly Tool

(Jacobsen PN JAC5084)

TN0940

5

4

2

3

1

TN3758

14

13

12

9

8

7

6

5

15

17

16

11

10

4

TN3757

1

3

2

1

2

Loading...

Loading...