Cutting

18 11/2020 243343V03_EN

2.4.2 Loading and starting

The machine is connected to the mains power supply and the main switch

is switched on (☞ „Switch-off at the end of production“ on page 57). .

The cleaning mode switch 5 is set to "OFF".

The safety covers are closed and locked.

The correct grid or grating device is installed.

There is an empty container under the discharge conveyor.

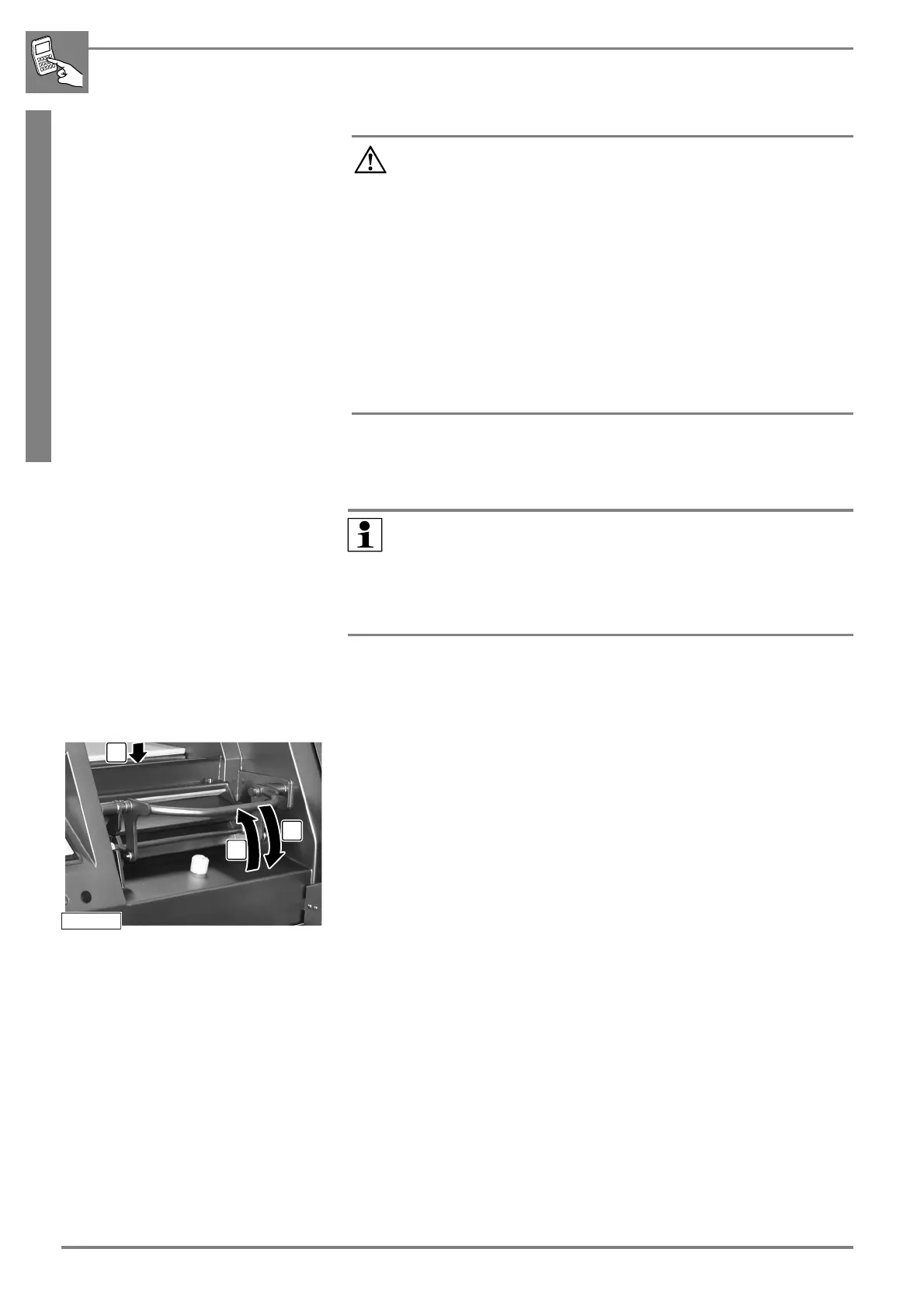

b Open the feed chamber by lifting the handle.

b Insert the product.

b Close the feed chamber by pressing down the handle.

The cutting process begins.

The cut product lands on the discharge conveyor and falls from there

into the container below.

While the cutting process is still in progress, you can already insert the

next product into the feed chamber. The machine starts the cutting pro-

cess when the feed chamber is closed.

Risk of injury on the separating slide!

The separating slide is used to close the filling chamber and

also to cut off overflowing material of the filling chamber. There

is a risk of crushing or cutting when pushing the separating slide

over the chamber.

b Insert only products that correspond to the dimensions of the

feed chamber!

b Overfilling the feed chamber must be avoided.

b Make absolutely sure that your hand is not on the level of the

separating slide when closing the chamber.

b For this reason, always wear your personal protective equip-

ment and operate the separating slide preferably with both

hands.

Note:

Ensure that the cleaning mode switch is set to the "OFF" posi-

tion.

If the switch is set to "ON", the machine will start the cleaning

mode after the cutting process has finished, this means the feed

moves into the cleaning position, the discharge conveyor starts.

Loading...

Loading...