8-22 Trio BASIC Commands

Motion and Axis Commands

Trio Motion Technology

Example 3:

A motor on Axis 0 is required to emulate a rotating mechanical

CAM

. The position is

linked to motion on axis 3. The “shape” of the motion profile is held in

TABLE

values

1000..1100.

CAMBOX(1000,1100,45.68,360,3,4) AXIS(0)

REP_OPTION=2' cancel repeating mode.

Note:

The system software resets bit 1 of

REP_OPTION

to 0 when the mode has been can-

celled.

800

This scales the

TABLE

values. Each

CAMBOX

motion would therefore

total 800*2000 encoder edges steps.

80

The distance on the product conveyor to link the motion to. The units

for this parameter are the programmed distance units on the link

axis.

15

This specifies the axis to link to.

2

This is the link option setting - Start at absolute position on the link

axis.

“start”

variable “start”. The motion will execute when the position “start” is

reaches on axis 15.

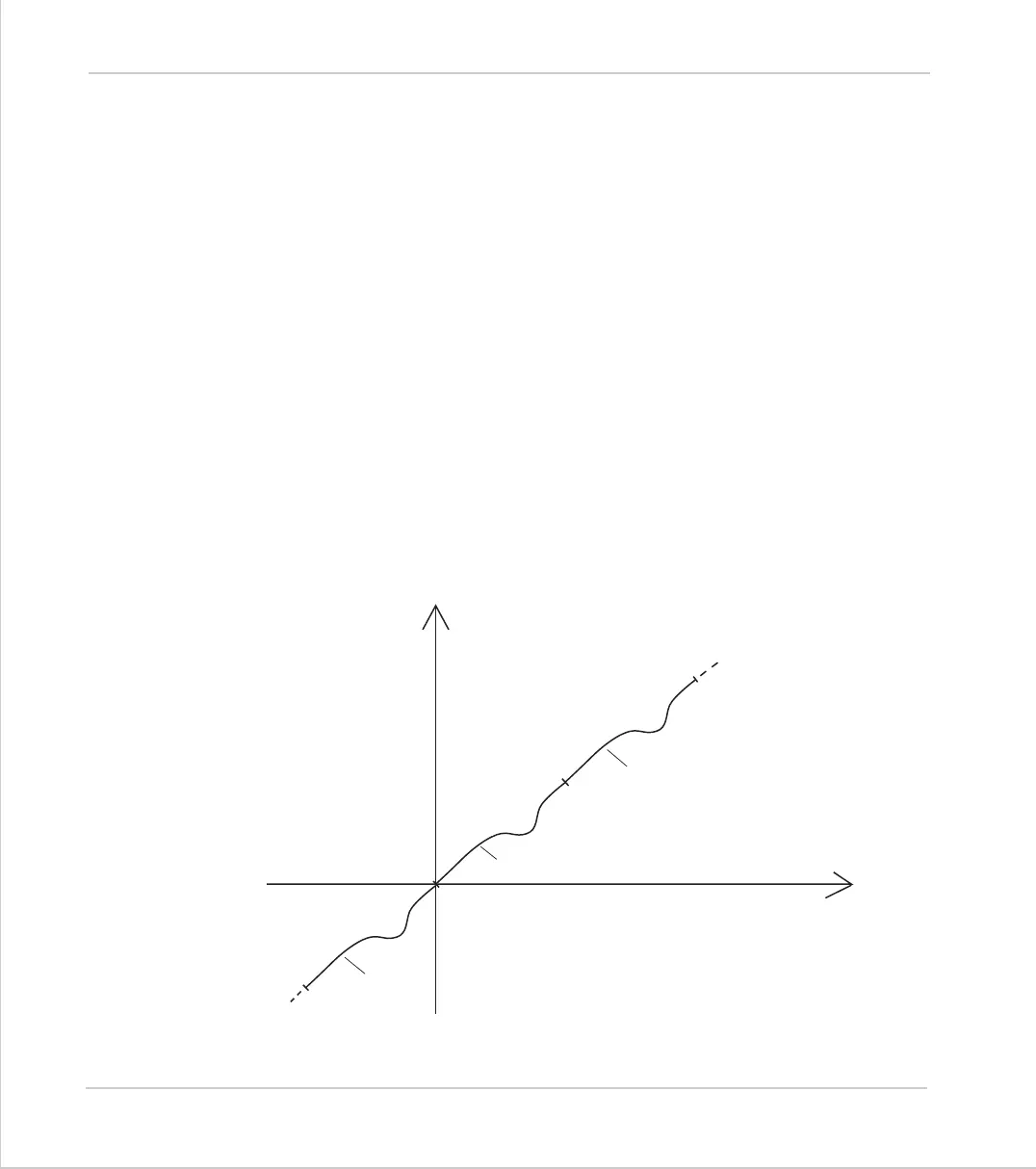

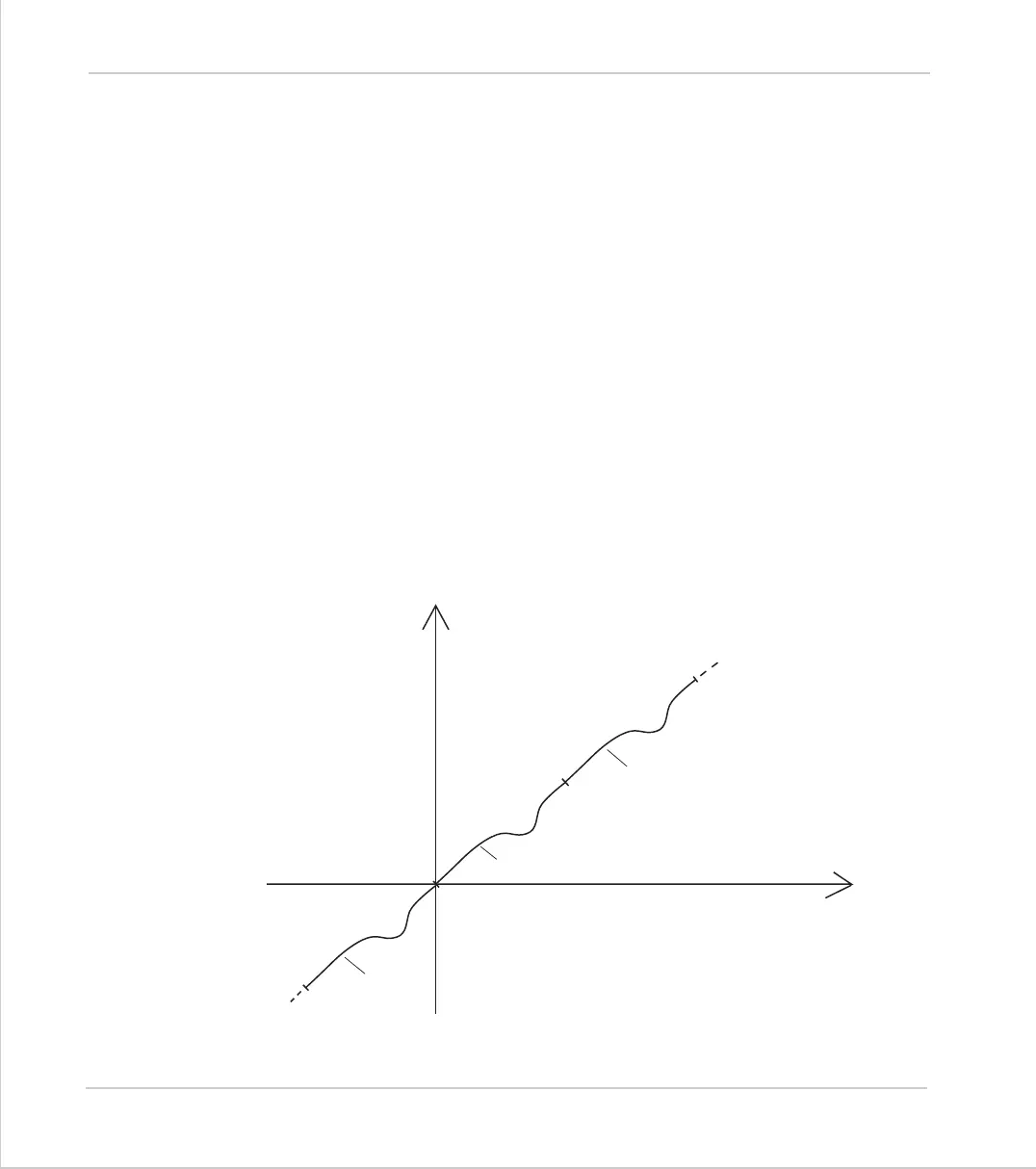

Axis 3 in reverse

auto-looping

CAMBOX

Axis 3 Position

Axis 0

Position

Shape from TABLE

values

Axis 3 forward with

auto-looping CAMBOX

Loading...

Loading...