8-24 Trio BASIC Commands

Motion and Axis Commands

Trio Motion Technology

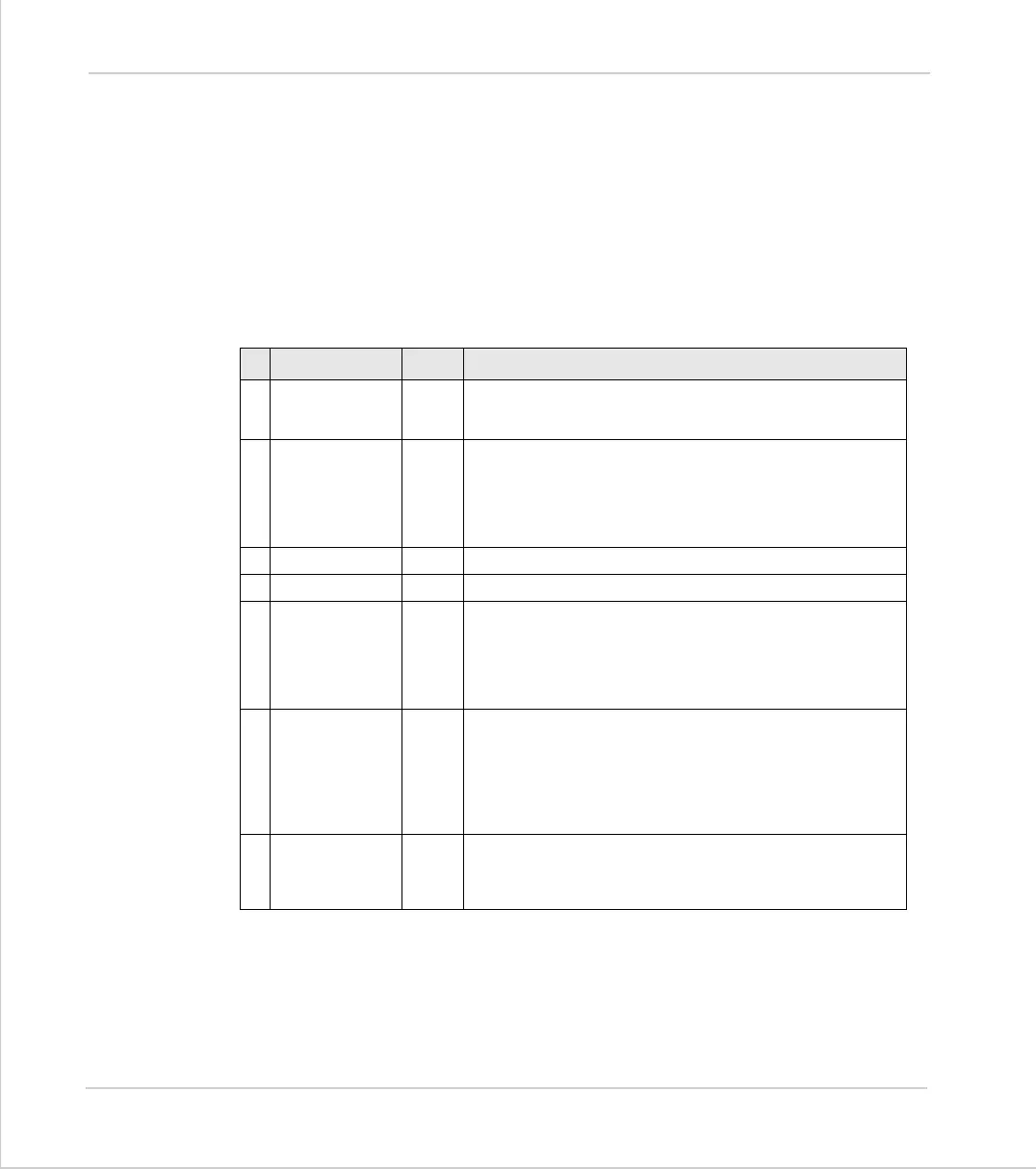

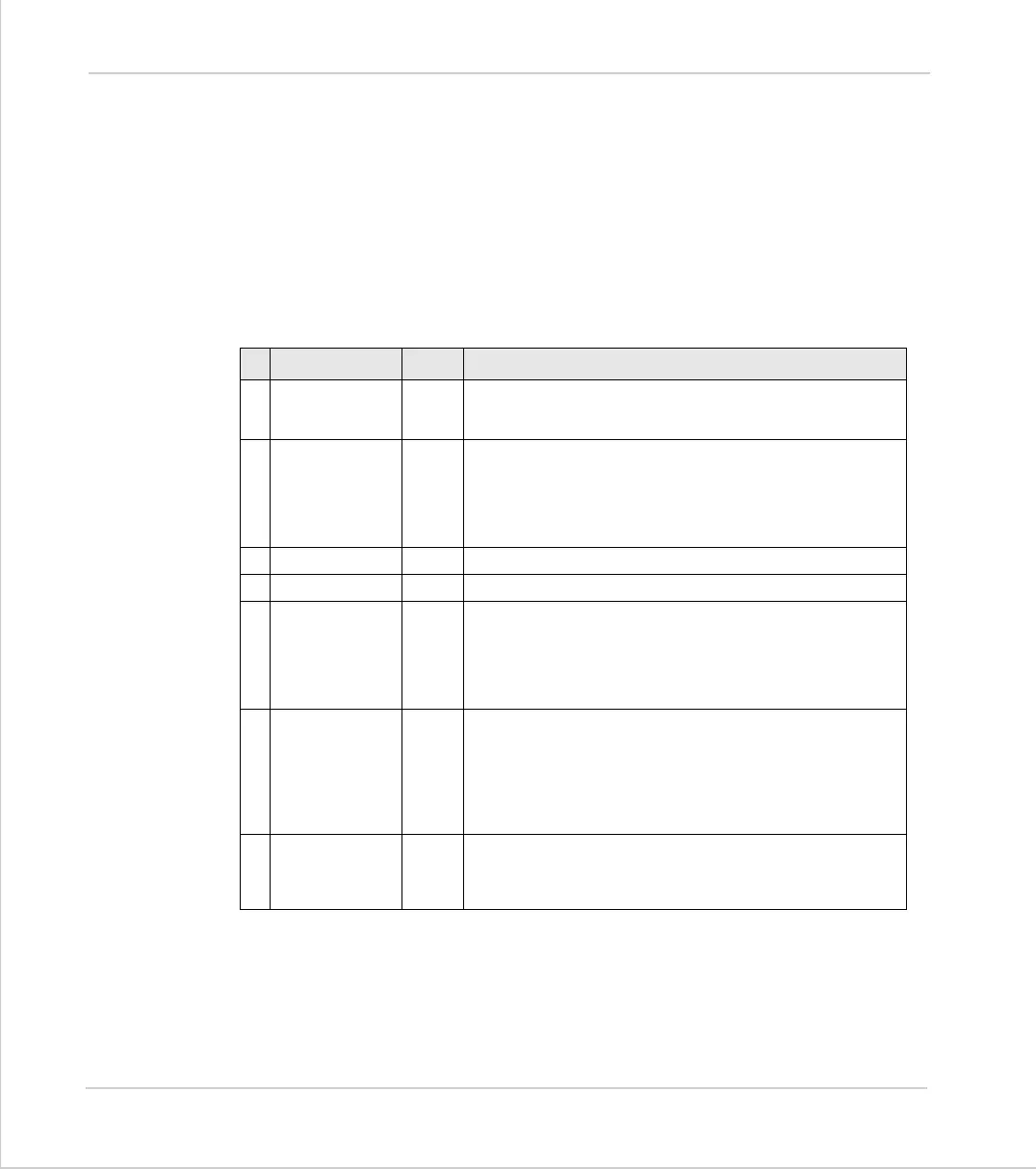

Control Block Parameters

Note:

READ/WRITE values can be written to by the user program during the pattern

CAM-

BOX

execution.

CONTROL BLOCK

This is pointed to by the third CAMBOX parameter in this

options mode only. It is of fixed length (7 table values). It is

important to note that the control block is modified during

the

CAMBOX operation. It must therefore be re-initialised

prior to each use.

PATTERN BLOCK

The start and end of this are pointed to by 2 of the CONTROL

BLOCK values. The pattern sequence is a sequence of scale

factors for the SHAPE.

R/W Description

0 CURRENT

POSITION

R The current position within the TABLE of the pattern

sequence. This value should be initialised to the START

PATTERN number.

1 FORCE POSITION R/W Normally this value is -1. If at the end of a SHAPE the user

program has written a value into this TABLE position the

pattern will continue at this position. The system software

will then write -1 into this position. The value written

should be inside the pattern such that the value:

CB(2)<=CB(1)<=CB(3)

2 START PATTERN R The position in the

TABLE

of the first pattern value.

3END PATTERN R The position in the

TABLE

of the final pattern value

4 REPEAT

POSITION

R/W The current pattern repeat number. Initialise this number

to 0. The number will increment when the pattern repeats

if the link axis motion is in a positive direction. The

number will decrement when the pattern repeats if the

link axis motion is in a negative direction. Note that the

counter runs starting at zero: 0,1,2,3…

5 REPEAT COUNT R/W Required number of pattern repeats. If -1 the pattern

repeats endlessly. The number should be positive. When

the ABSOLUTE value of CB(4) reaches CB(5) the

CAMBOX

finishes if CB(6)=-1. The value can be set to 0 to terminate

the

CAMBOX

at the end of the current pattern. See note

below on REPEAT COUNT in the case of negative motion on

the link axis.

6NEXT CONTROL

BLOCK

R/W If set to -1 the pattern will finish when the required

number of repeats are done. Alternatively a new control

block pointer can be used to point to a further control

block.

Loading...

Loading...