HP10E / HP12E / HP15E / HP20E - Dairy design 7. Cleaning

7-11© VEMAG 2013

7.3 Cleaning the machine

All product contact and incidental contact areas are ready to be cleaned

and then inspected. Clean the machine housing, the hopper, the cover,

the feed screw and all the parts which have been removed thoroughly

with hot water and a brush or use low-pressure mechanical cleaning

equipment (max. 25 bar or 367 psig).

The machine is constructed of corrosion resistant materials. The machine

will self drain when level, but should be checked to make sure no stan-

ding water remains after cleaning. After inspecting all surfaces for cleanli-

ness, an EPA approved sanitizing agent may be applied.

Warning!

Never aim the jet of water directly at the double screw drive, the sealing

elements and the machine control panel when using low-pressure clea-

ning equipment and keep the nozzle at the distance from the surface of

the machine specied for the cleaning equipment.

In addition to the instructions in the cleaning schedule, generally-applica-

ble and product-specic hygiene regulations should be followed.

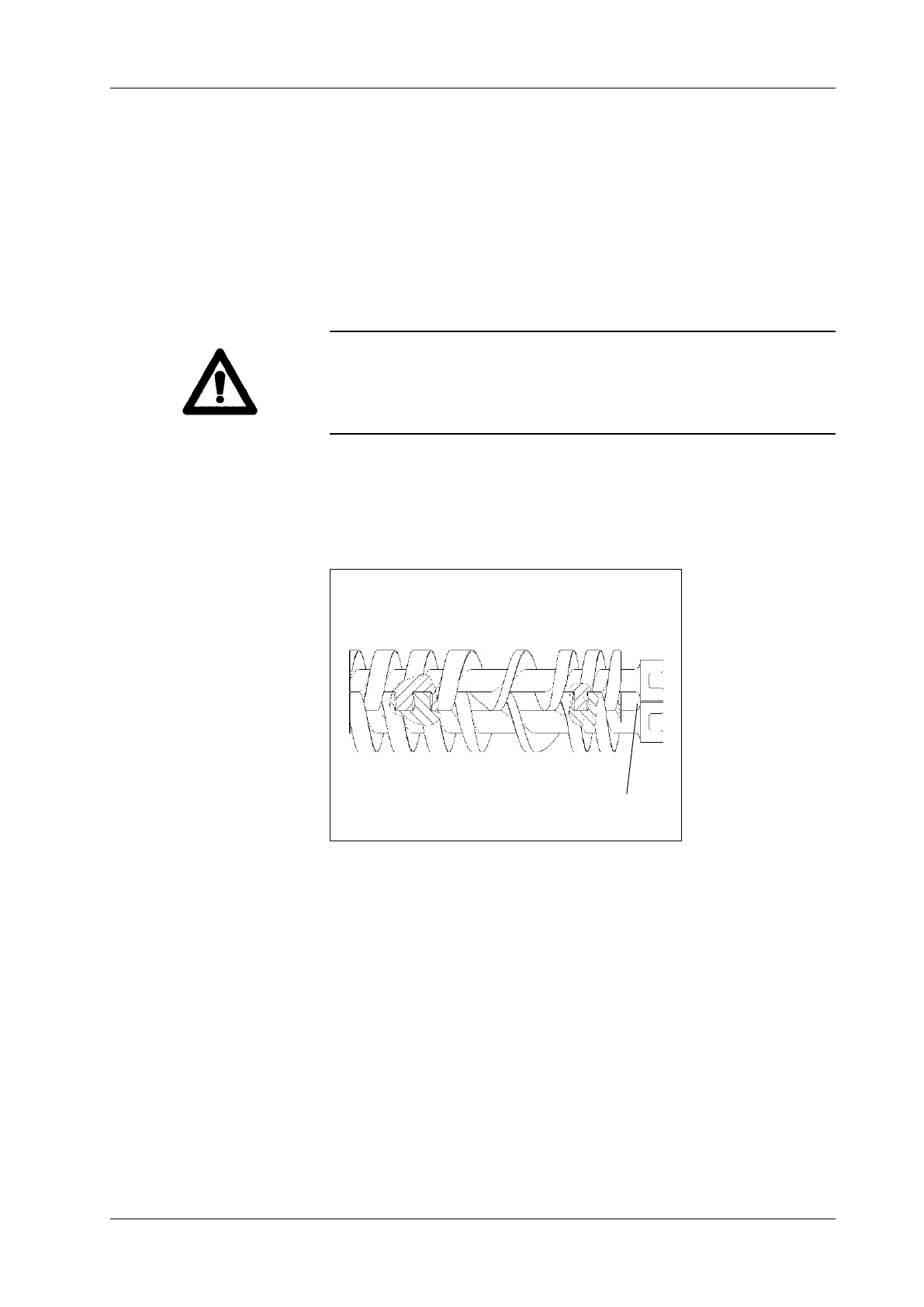

When cleaning the double screws, pay particular attention to the joints (1)

between the screw and the coupling claw.

1 Joint

Fig. 7-14

Double screws

1

Loading...

Loading...