HP10E / HP12E / HP15E / HP20E - Dairy design9. Troubleshooting

9-2 © VEMAG 2013

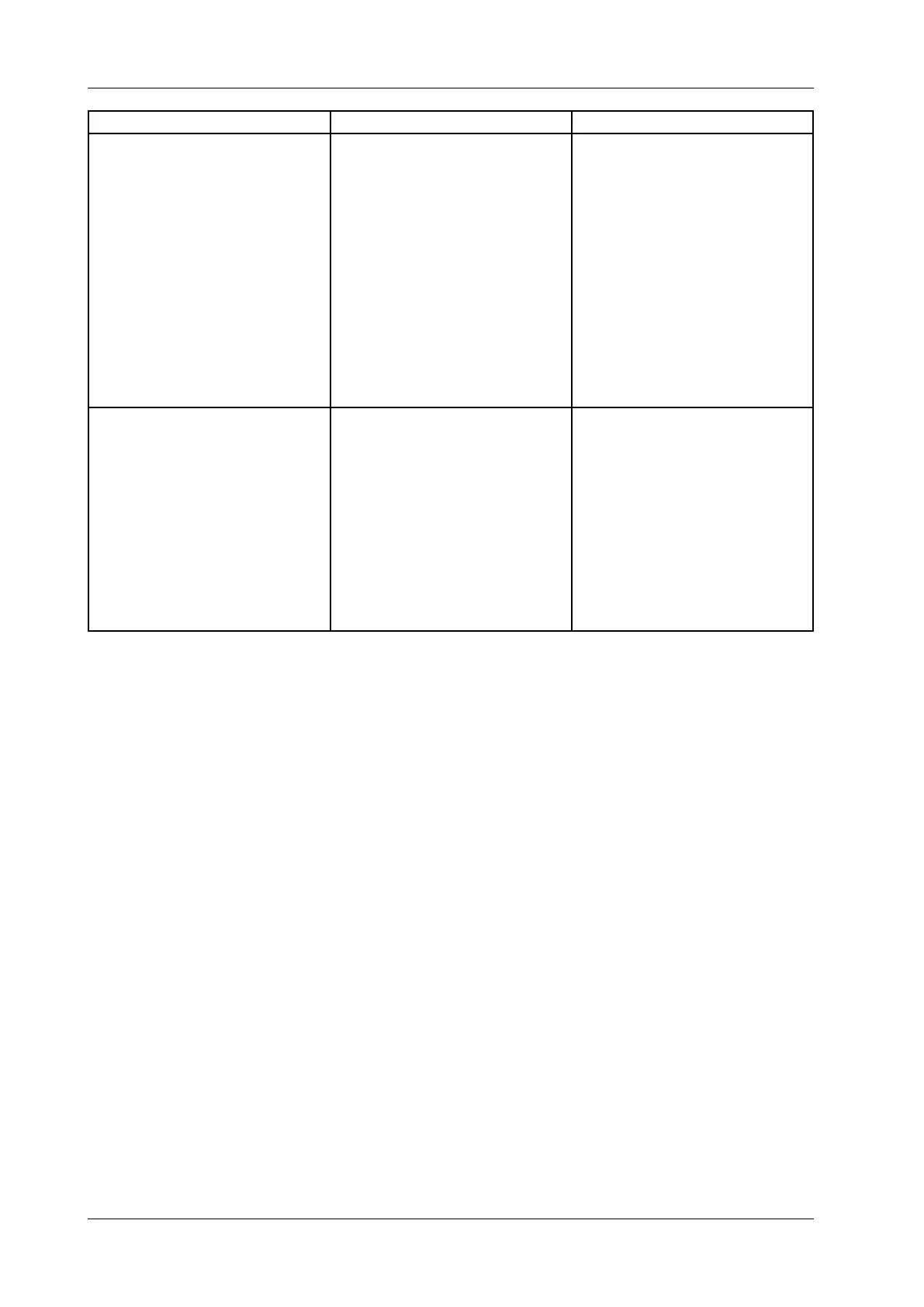

Fault Cause Remedy

Weight uctuations. Unsuitable double screw.

Double screw and double screw

housing worn.

Insufcient vacuum, vacuum unsta-

ble (vacuum display uctuating).

Deformed feed screw, wrong double

screw set.

Check double screw, use 48 mm

double screw pitch for portioning

small portions.

Measure double screw and double

screw housing for wear with a feeler

gauge. Air gap between screw and

housing max. 0.5 mm.

Close air relief bores in double screw

housing. Check vacuum system.

Check feed screw. Gap between

bottom edge of feed screw and top

edge of housing must be

110 - 120 mm.

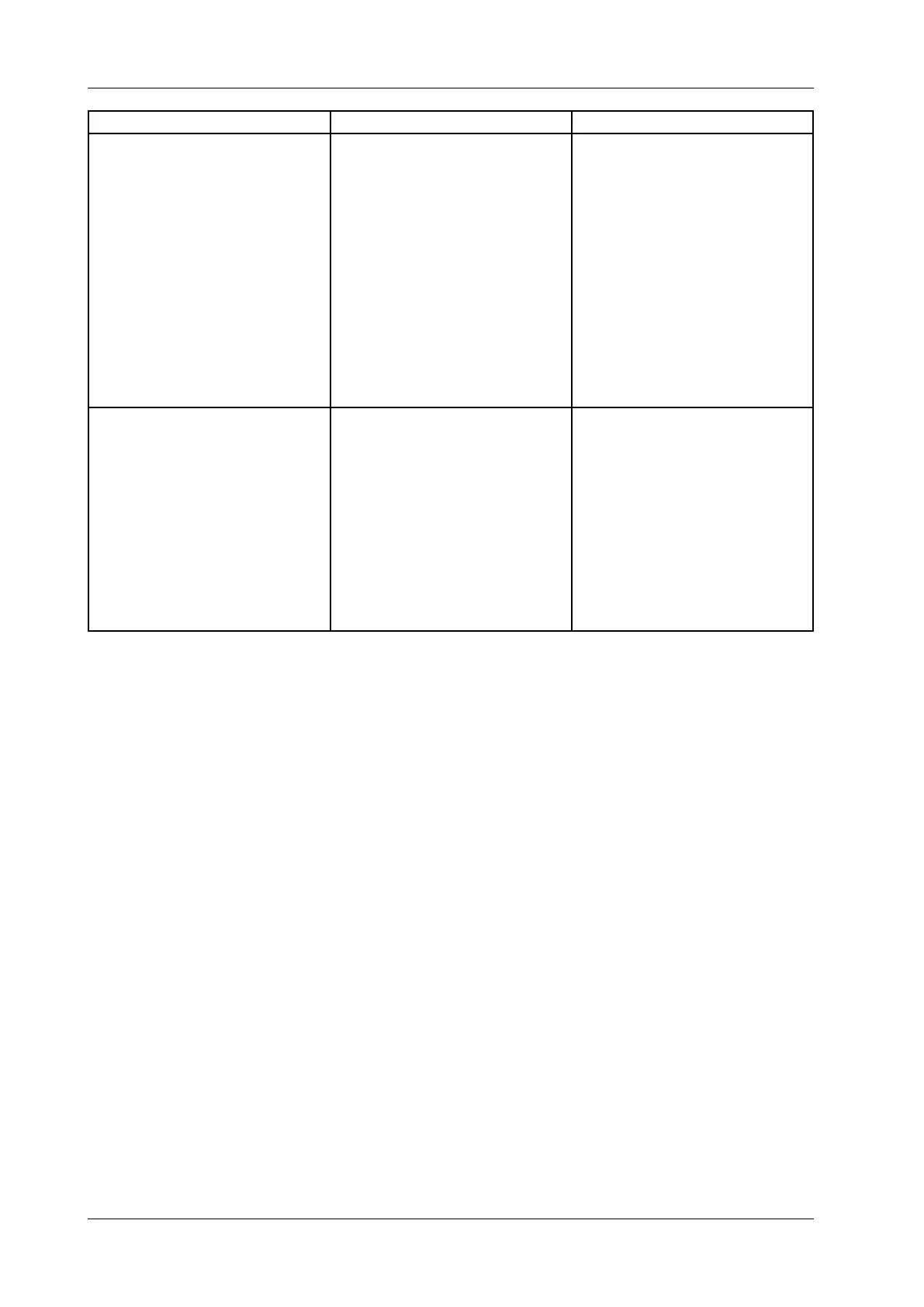

Drop in output. Double screw and double screw

housing worn.

Vacuum too low.

Deformed feed screw.

Check double screw and double

screw housing for wear. Measure

air gap between double screw and

double screw housing.

Check vacuum setting. The vacuum

should be set so that there is no

product in the vacuum pot.

Check feed screw. Gap between the

bottom edge of the feed screw and

the top edge of the housing must be

110 - 120 mm.

Loading...

Loading...