ENGINE

B2420, WSM

1-S17

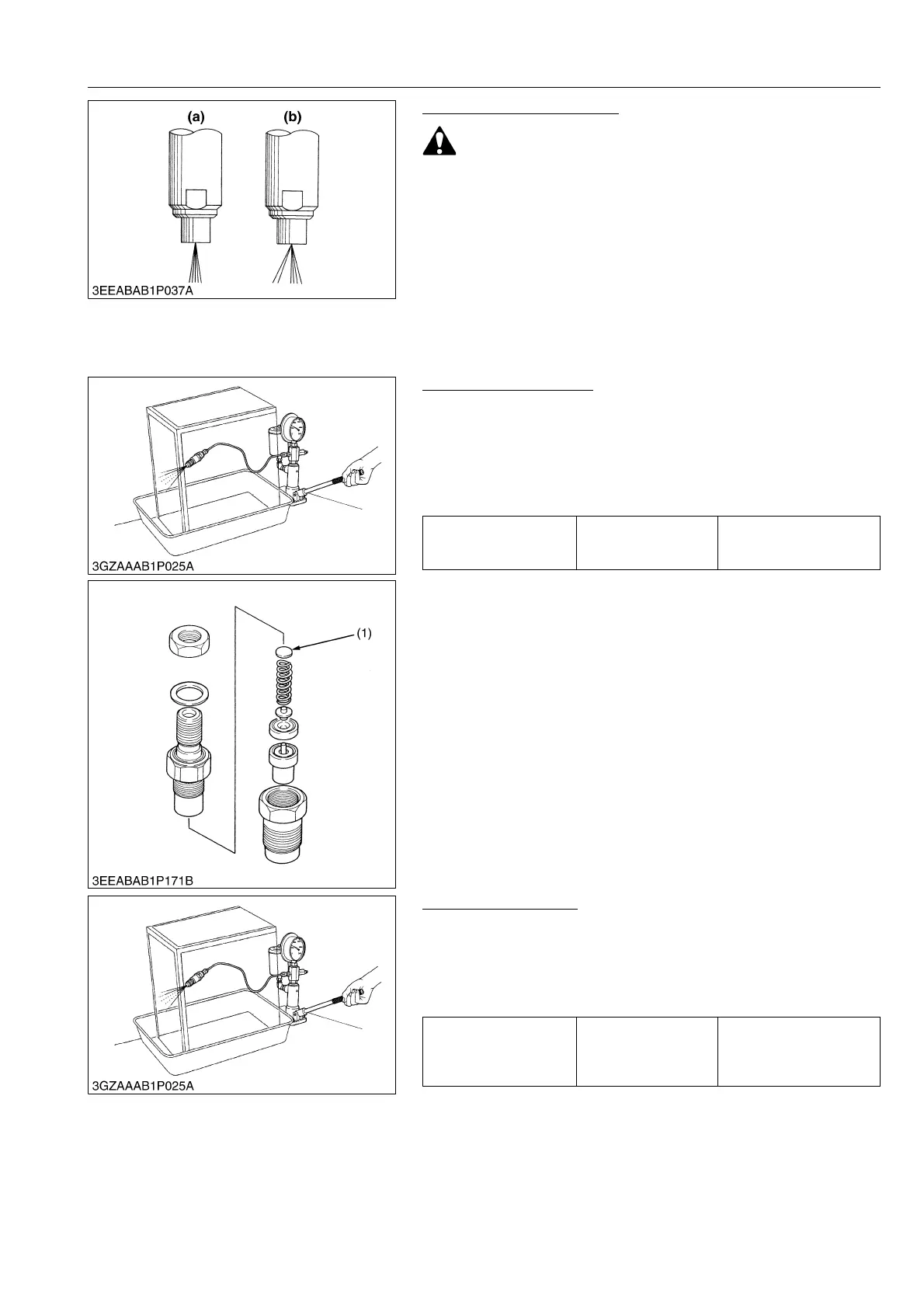

Nozzle Spraying Condition

• Check the injection pressure and condition after

confirming that there is nobody standing in the direction

the fume goes.

• If the fume from the nozzle directly injects the human body,

cells may be destroyed and blood poisoning may be

caused.

1. Set the injection nozzle to a nozzle tester, and check the nozzle

spraying condition.

2. If the spraying condition is defective, replace the nozzle piece.

9Y1210436ENS0015US0

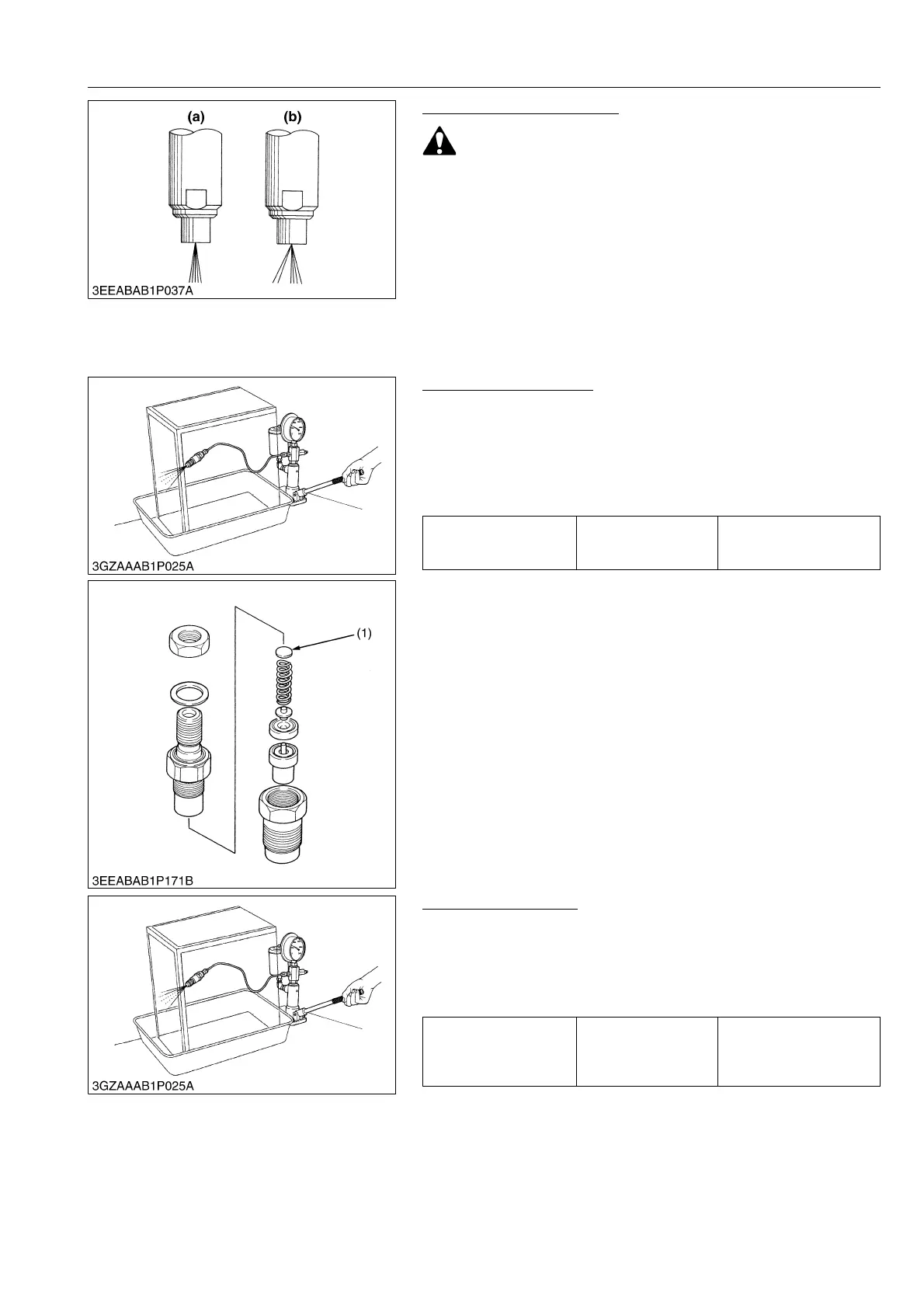

Fuel Injection Pressure

1. Set the injection nozzle to a nozzle tester (Code No.

07909-31361).

2. Slowly move the tester handle to measure the pressure at which

fuel begins jetting out from the nozzle.

3. If the measurement is not within the factory specifications,

replace the adjusting washer (1) in the nozzle holder to adjust it.

(Reference)

• Pressure variation with 0.01 mm (0.0004 in.) difference of

adjusting washer thickness. Approx. 235 kPa (2.41 kgf/cm

2

,

34.1 psi).

9Y1210436ENS0016US0

Valve Seat Tightness

1. Set the injection nozzle to a nozzle tester (Code No.

07909-31361).

2. Raise the fuel pressure, and keep at 12.75 MPa (130.0 kgf/cm

2

,

1849 psi) for 10 seconds.

3. If any fuel leak is found, replace the nozzle piece.

9Y1210436ENS0017US0

(a) Good (b) Bad

Fuel injection pressure Factory specification

13.73 to 14.70 MPa

140.0 to 150.0 kgf/cm

2

1992 to 2133 psi

(1) Adjusting Washer

Valve seat tightness Factory specification

No fuel leak at

12.75 MPa

130.0 kgf/cm

2

1849 psi

Loading...

Loading...