Deceleration time is too short and regenerative

energy flows from the motor into the drive.

• Increase the deceleration time (C1-02, -04).

•

Install a braking resistor or a dynamic braking resistor unit.

• Enable stall prevention during deceleration (L3-04 = “1”).

Stall prevention is enabled as the default setting.

Excessive braking load.

The braking torque was too high, causing regenerative energy to charge the DC bus.

Reduce the braking torque, use a braking option, or lengthen decel time.

Surge voltage entering from the drive input

power.

Install a DC link choke.

Note: Voltage surge can result from thyristor convertor and phase advancing capacitor using same drive

main input power supply.

Ground fault in the output circuit causing the

DC bus capacitor to overcharge.

• Check the motor wiring for ground faults.

• Correct grounding shorts and turn the power back on.

Excessive regeneration when overshoot

occurs after acceleration.

• Lengthen the S-curve at acceleration end.

Drive input power voltage is too high.

• Check the voltage.

• Lower drive input power voltage within the limits listed in the specifications.

The dynamic braking transistor is damaged. Replace the drive.

The braking transistor is wired incorrectly.

• Check braking transistor wiring for errors.

• Properly rewire the braking resistor device.

Drive fails to operate properly due to noise

interference.

• Review the list of possible solutions provided for controlling noise.

• Review the section on handling noise interference and check the control circuit lines, main circuit lines

and ground wiring.

Motor hunting occurs.

• Adjust the parameters that control hunting.

• Set the hunting prevention gain (n1-02).

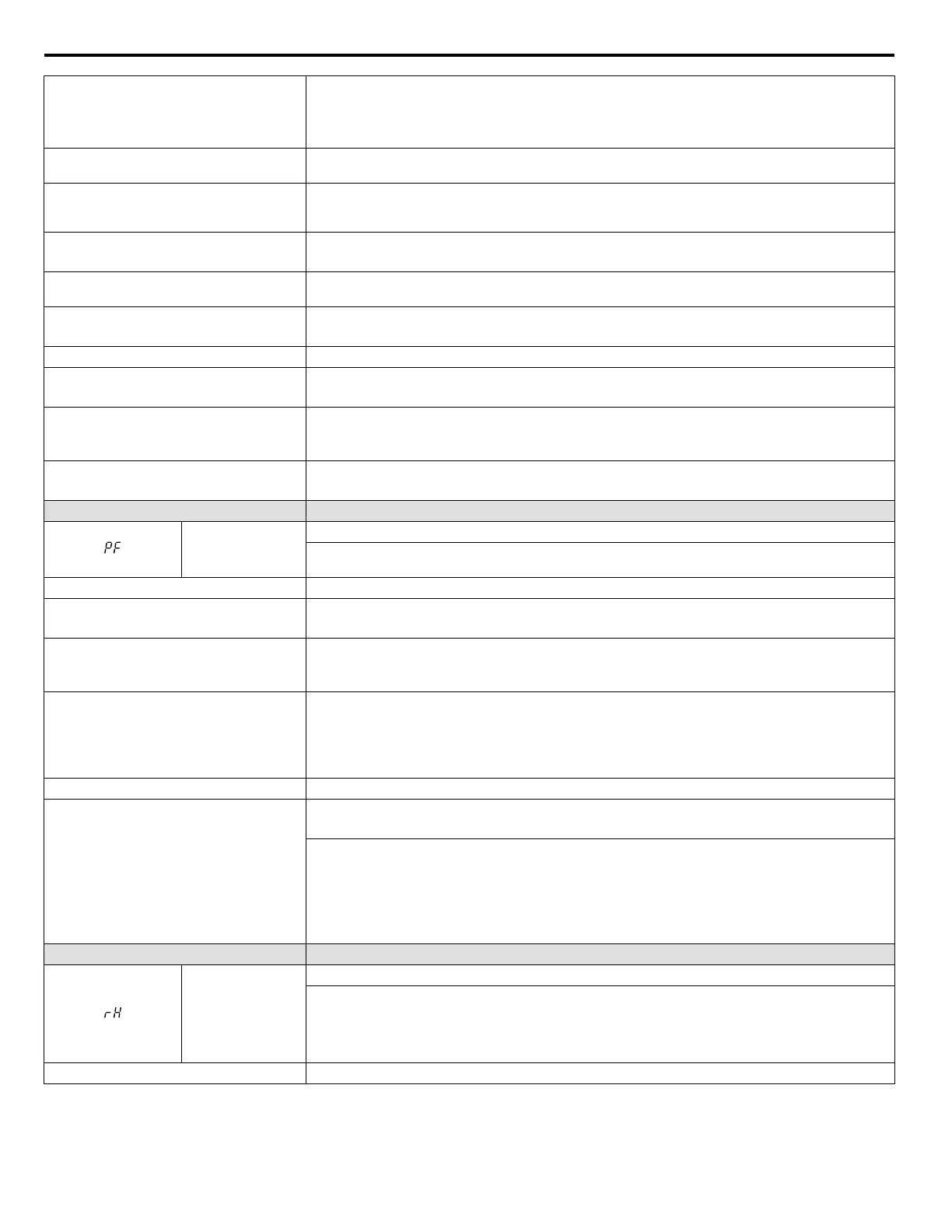

LED Operator Display Fault Name

PF

Input Phase Loss

Drive input power has an open phase or has a large imbalance of voltage between phases. Detected when

L8-05 = 1 (enabled).

Cause Possible Solution

There is phase loss in the drive input power.

• Check for wiring errors in the main circuit drive input power.

•

Correct the wiring.

There is loose wiring in the drive input power

terminals.

• Ensure the terminals are tightened properly.

• Apply the tightening torque specified in this manual to fasten the terminals. Refer to Wire Gauges

and Tightening Torque on page 39

There is excessive fluctuation in the drive

input power voltage.

• Check the voltage from the drive input power.

• Review the possible solutions for stabilizing the drive input power.

• Disable Input Phase Loss Detection (L8-05 = “0”). PF is detected if DC bus ripple is too high. If it is

disabled, there is no fault but the ripple is still too high, thereby the capacitors are stressed more and

lose lifetime.

There is poor balance between voltage phases. • Stabilize drive input power or disable phase loss detection.

The main circuit capacitors are worn.

• Check the maintenance time for the capacitors (U4-05).

• Replace the drive if U4-05 is greater than 90%.

• Check for anything wrong with the drive input power.

• If nothing is wrong with the drive input power, try the following solutions if the alarm continues:

• Disable Input Phase Loss Protection selection (L8-05 = “0”). PF is detected if DC bus ripple is too high.

If it is disabled, there is no fault but the ripple is still too high, thereby the capacitors are stressed more

and lose lifetime.

• Replace the drive.

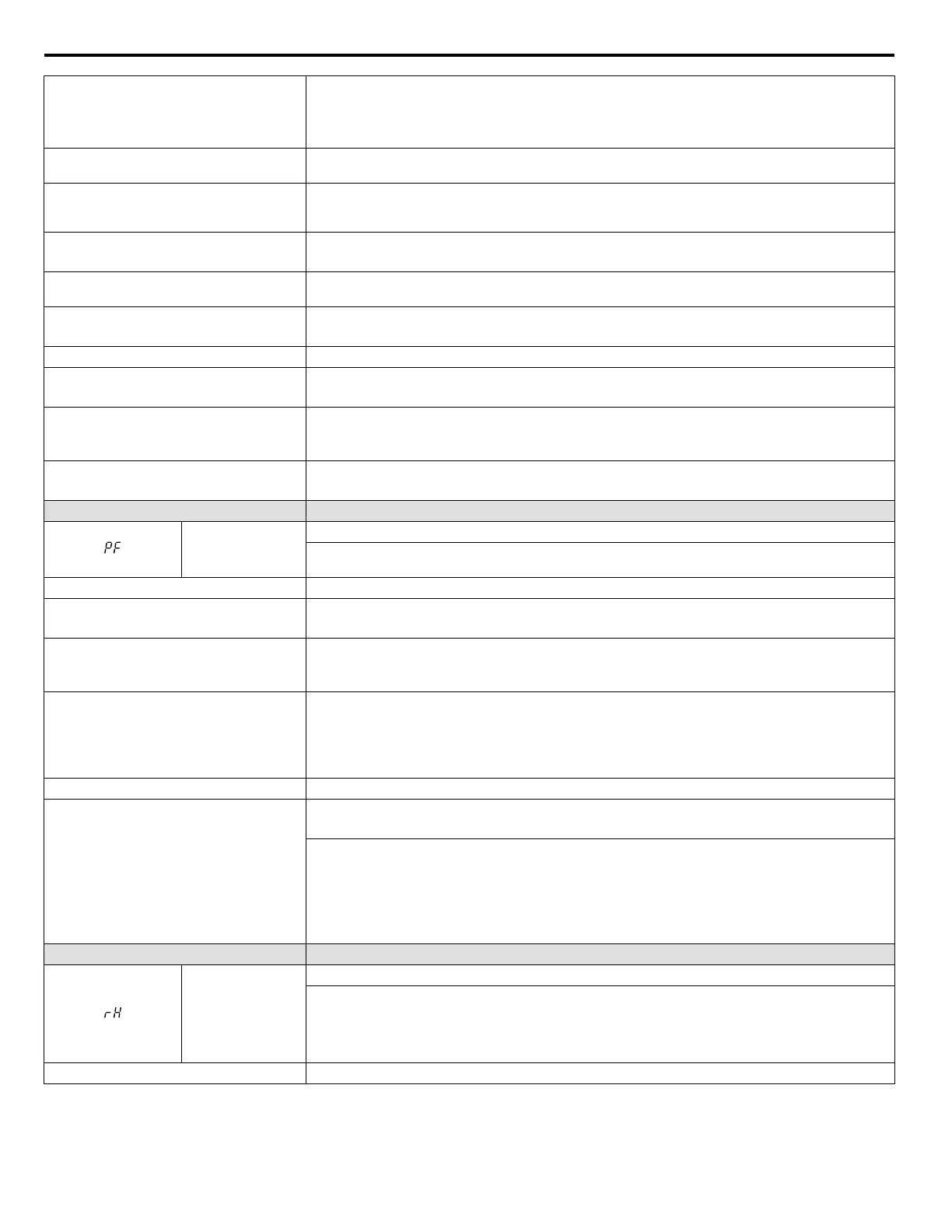

LED Operator Display Fault Name

rH

Braking Resistor Overheat

Braking resistor protection was triggered.

Fault detection is enabled when

L8-01 = 1 (disabled as a default).

Note: The magnitude of the braking load trips the braking resistor overheat alarm, NOT the surface

temperature. Using the braking resistor more frequently than its rating trips the alarm even when the

braking resistor surface is not very hot.

Cause Possible Solution

6.4 Fault Detection

138

YASKAWA ELECTRIC SIEP C710606 31B YASKAWA AC Drive – J1000 Technical Manual

http://nicontrols.com

Loading...

Loading...