n

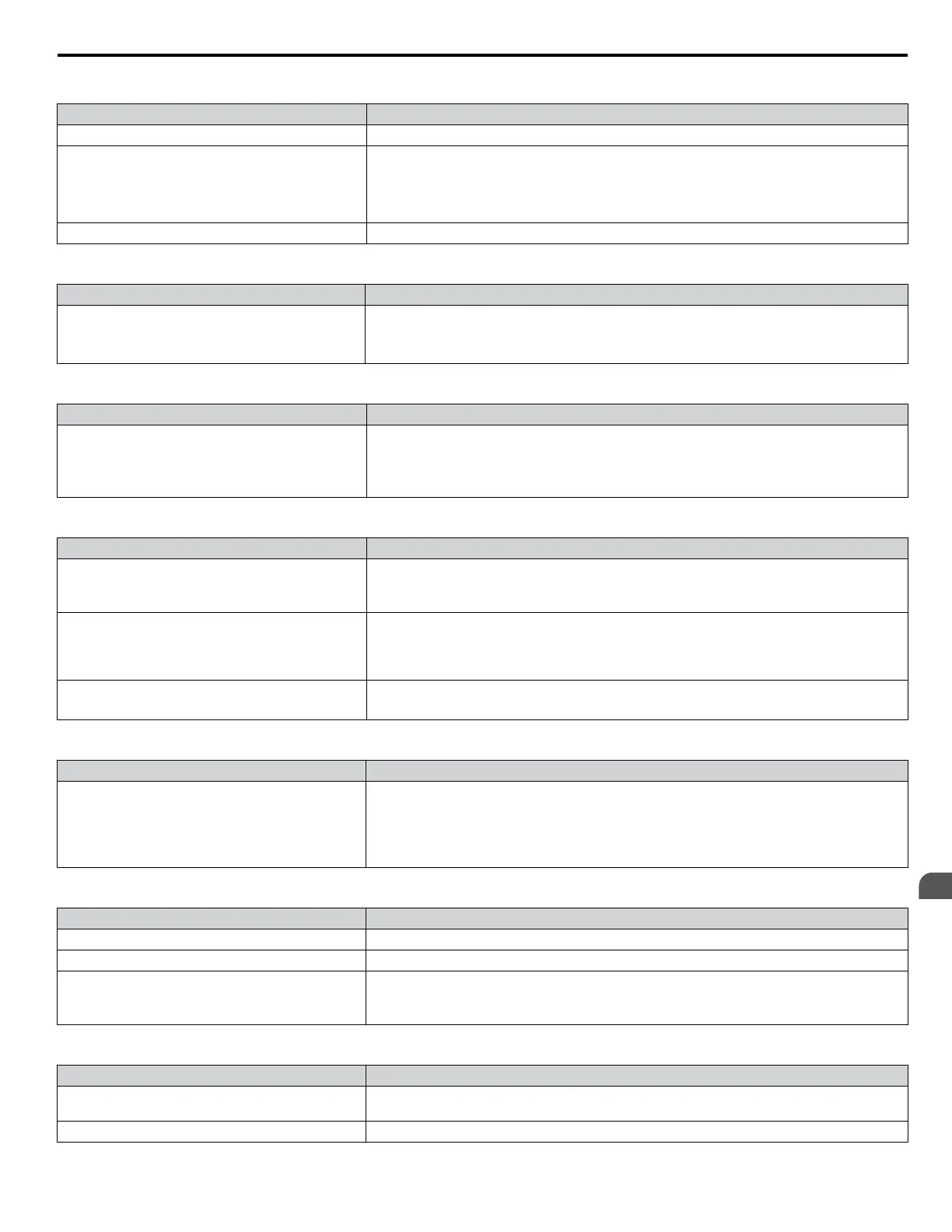

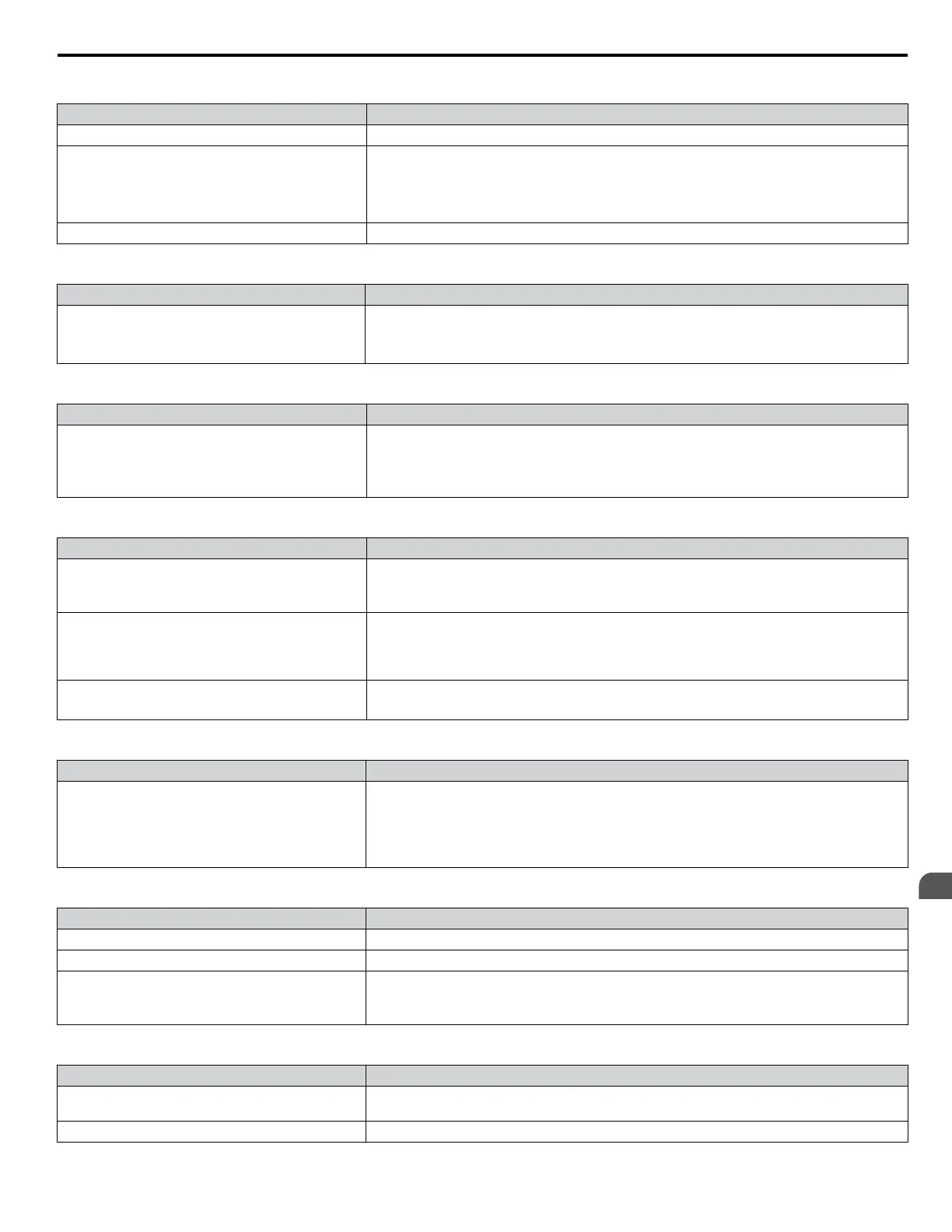

Oscillation or Hunting

Cause Possible Solutions

Insufficient tuning. Adjust Hunting prevention Gain Setting (n1-02).

The frequency reference is assigned to an external

source and the signal is noisy.

• Ensure that noise is not affecting the signal lines.

•

Separate main circuit wiring and control circuit wiring.

• Use twisted-pair cables or shielded wiring for the control circuit.

• Increase the analog input time filter constant (H3-13).

The cable between the drive and motor is too long. • Reduce the length of the cable.

n

Motor Rotates After the Drive Output is Shut Off

Cause Possible Solutions

Low DC Injection Braking and the drive cannot

decelerate properly.

• Adjust the DC Injection braking settings.

•

Increase the value of b2-02 (DC Injection Braking Current).

• Increase the b2-04 (DC Injection Braking Time at Stop).

n

ov or Speed Loss Occurs When Starting into a Rotating Load

Cause Possible Solutions

The load is already rotating when the drive is trying to

start it.

• Stop the motor using DC Injection braking. Restart the motor.

•

Increase the value of b2-03 (DC Injection Braking Time at start).

•

Set a multi-function input terminal for external Speed Search command (H1-oo=“61” or

“62” during restart).

n

Output Frequency is not as High as Frequency Reference

Cause Possible Solutions

Frequency reference is set within the range of the Jump

Frequency.

• Adjust the parameters used for the Jump Frequency function (d3-01, d3-02).

•

Enabling the Jump Frequency prevents the drive from outputting the frequencies specified in

the Jump Frequency range.

Upper limit for the frequency reference has been

exceeded.

• Set the maximum output frequency and the upper limit for the frequency reference to more

appropriate values (

E1-04, d2-01).

• The following calculation yields the upper value for the output frequency = E1-04 x d2-01 /

100

Large load triggered Stall Prevention function during

acceleration.

• Reduce the load.

•

Adjust the Stall Prevention level during acceleration (L3-02).

n

Buzzing Sound from Motor at 2 kHz

Cause Possible Solutions

Exceeded 110% of the rated output current of the drive

while operating at low speeds.

• If the output current rises too high at low speeds, the carrier frequency automatically reduces

and causes a whining or buzzing sound.

•

If the sound is coming from the motor, disable carrier frequency derating (L8-38 = “0”).

• Disabling the automatic carrier frequency derating increases the chances of an overload fault

(oL2). Switch to a larger capacity motor if oL2 faults occur too frequently.

n

Motor Does Not Operate When the RUN Button on the Digital Operator is Pressed

Cause Possible Solutions

The LOCAL/REMOTE mode is not selected properly. Press the LOCAL/REMOTE button to switch. The LO/RE LED should be on for LOCAL mode.

The drive is not in drive mode. A run command will not be issued. Exit to the drive mode and cycle the run command.

The frequency reference is too low.

• If the frequency reference is set below the frequency set in E1-09 (Minimum Output

Frequency), the drive will not operate.

•

Raise the frequency reference to at least the minimum output frequency.

n

Motor Does Not Operate When an External Run Command is Input

Cause Possible Solutions

The LOCAL/REMOTE mode is not selected properly.

Press the LOCAL/REMOTE button to switch. The LO/RE LED should be off for REMOTE

mode.

The drive is not in Drive Mode. A run command will not be issued. Exit to the Drive mode and cycle the run command.

6.8 Troubleshooting without Fault Display

YASKAWA ELECTRIC SIEP C710606 31B YASKAWA AC Drive – J1000 Technical Manual

151

6

Troubleshooting

http://nicontrols.com

Loading...

Loading...