A Accessories and platepads

(Bravo SRT only) Setting up an LT tip box location

172

Bravo Platform User Guide

(Bravo SRT only) Setting up an LT tip box location

About this topic

Read this topic if you have a Bravo SRT Platform and you are using the 250-µL tips. The

height limitation on the Bravo SRT requires a special platepad and a deck location

configured for the 250-µL tip box operations.

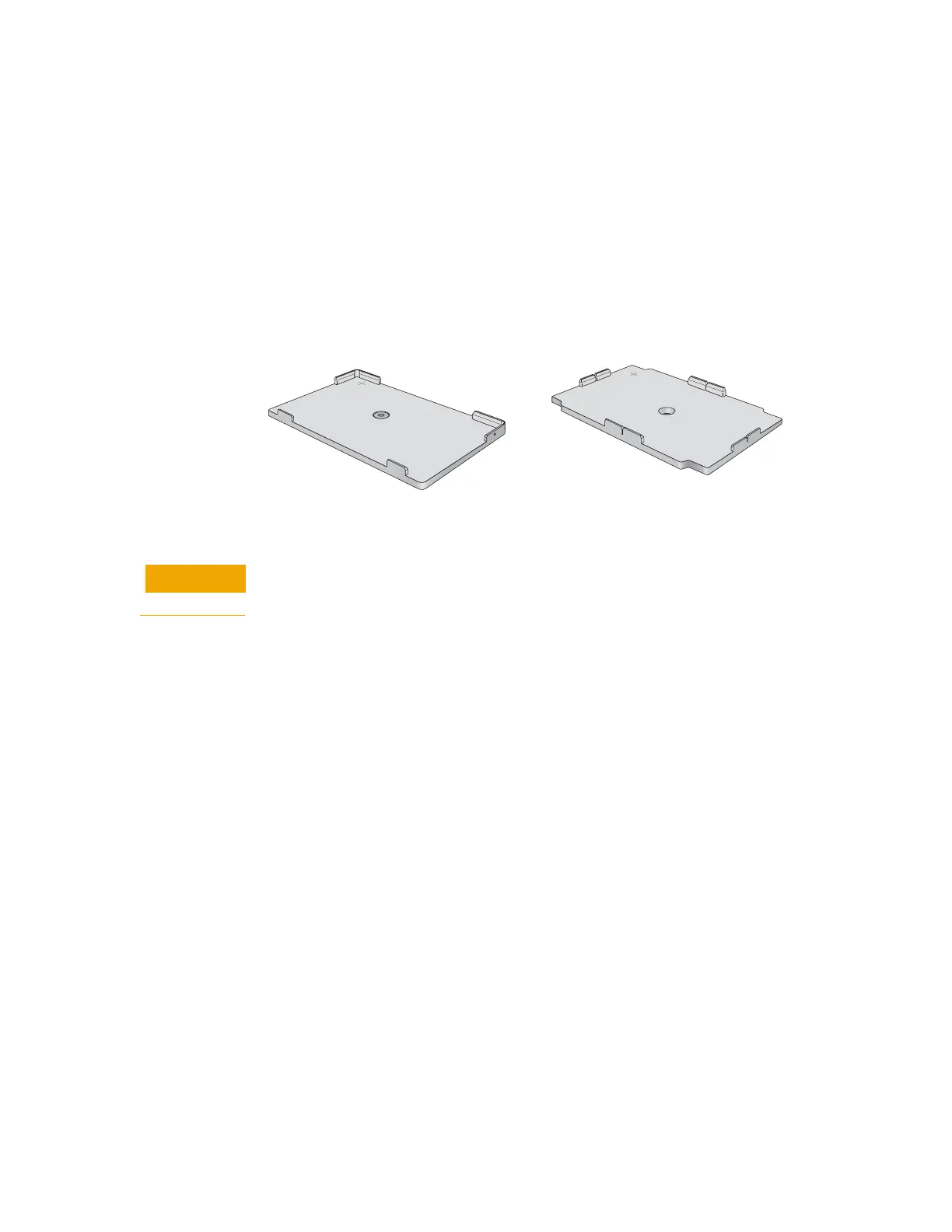

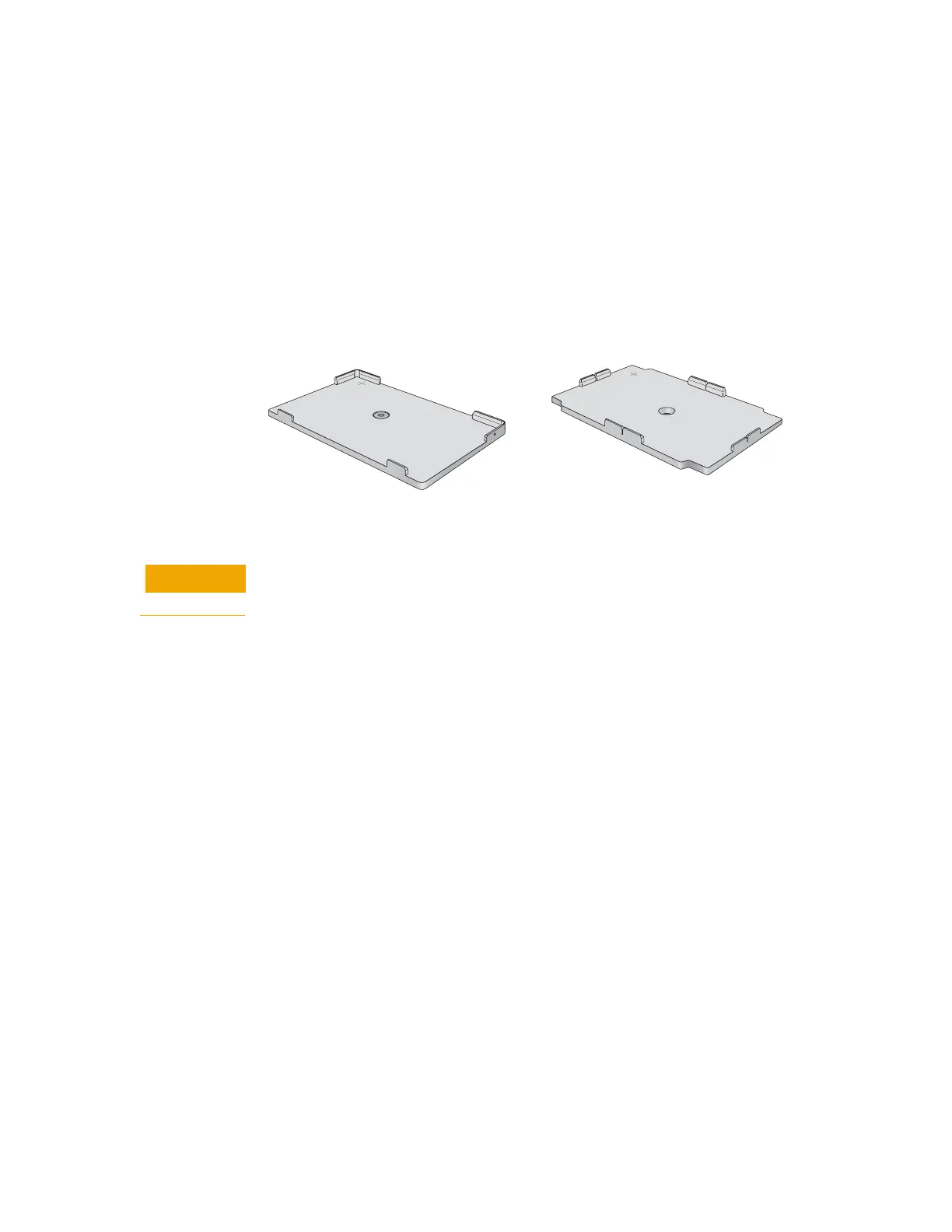

The following figure shows the SRT platepad options for tip operations.

Figure

SRT platepads: (A) ST tip loading station, and (B) SRT platepad for 250 µL LT tip boxes

Before you start

To prevent potential hardware crashes when using 250-µL tips, make sure you

understand the following limitations of the z-axis clearance on the Bravo SRT.

• Be aware that the Bravo SRT has insufficient clearance to move labware if the 250-

µL tips are installed on the liquid-handling head. The Bravo SRT can move labware

only if 250-µL tips are not on the liquid-handling head.

• Limit tips on and tips off tasks to deck locations where an SRT 250-µL tip box

platepad is physically installed and configured in the Bravo Diagnostics software.

This special platepad provides additional z-axis clearance, and is designed for a tip

box that holds 96 250-µL tips.

• Use labware classes for each deck location so that the 250-µL tip box operations

are not attempted at deck locations with insufficient z-axis clearance.

• Use VWorks Task Groups to ensure that tips on and tips off tasks are performed

before plate movement tasks in the protocol.

Ensure that you have the following:

• M5 hex wrench for removing a standard SRT platepad

• SRT platepad for 250-µL tip box

• Star-head screw and wrench for installing the SRT 250-µL tip box platepad

Loading...

Loading...