3-5

Techniques of Sterilization Operator Manual 387366-389

3.4 Sterilization

Techniques and

Recommendations for

Liquids

Important: Read this section before using the sterilizer to

sterilize liquids.

Recommended minimum exposure time for a 1 liter liquid flask

is 45 minutes at 121°C (250°F). Volumes greater or less than

1 liter must be determined.

The minimum exposure (sterilization) assumes the use of vented

bottles or Erlenmeyer flasks and includes the time required to bring

the solution up to the sterilization temperature plus the time required

to achieve sterilization. Variables that might effect this time include

flask/bottle material and viscosity of the liquid to be processed.

NOTE: Use load probes and F

o

option to optimize cycle times.

The use of borosilicate glass is required because it is a superior

glass capable of resisting thermal shock. If glass less thermally

resistant is used, a greater potential for bursting exists.

Vented closures are required because, by design, they release

internal pressure build-up by automatically venting the containers,

whereas pressure in unvented containers remains until the contents

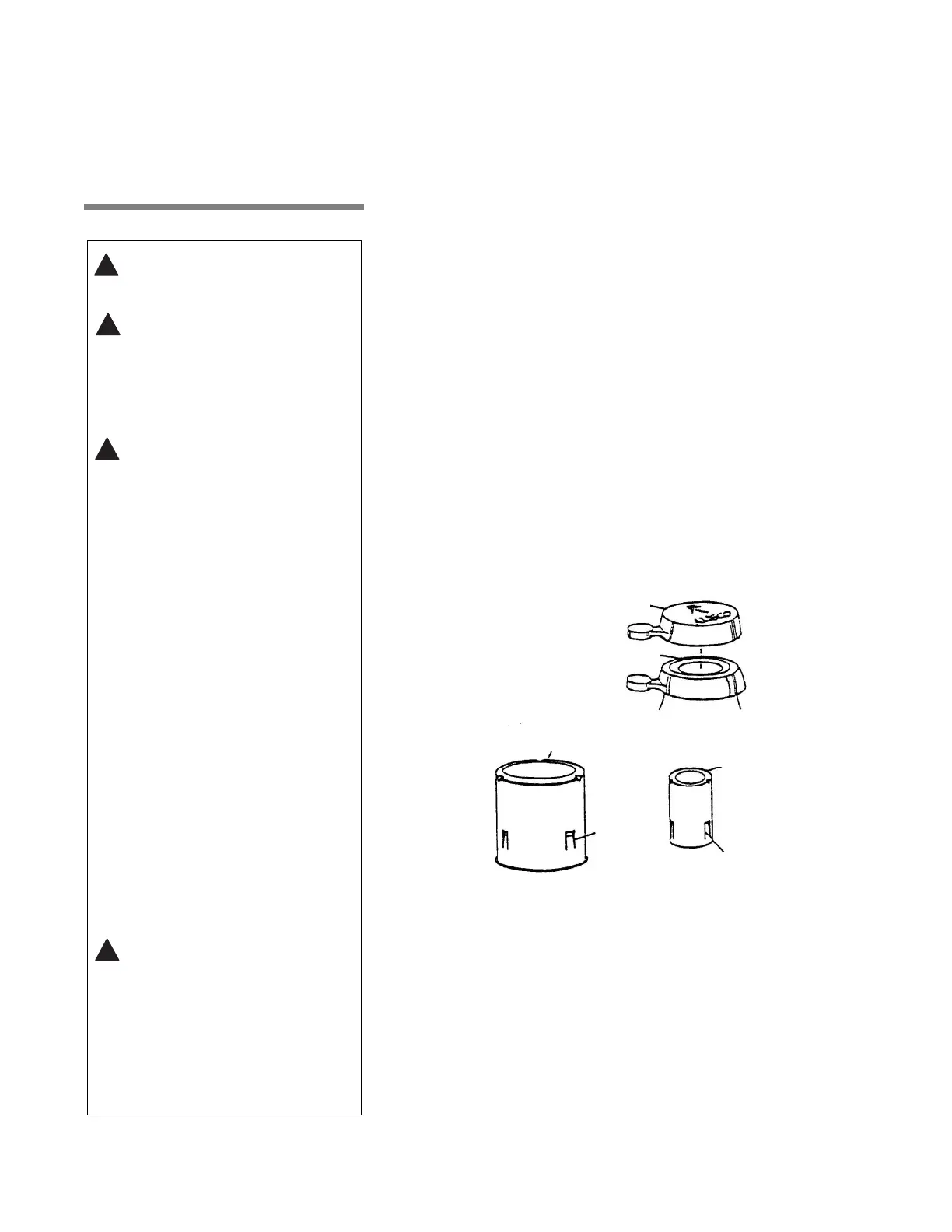

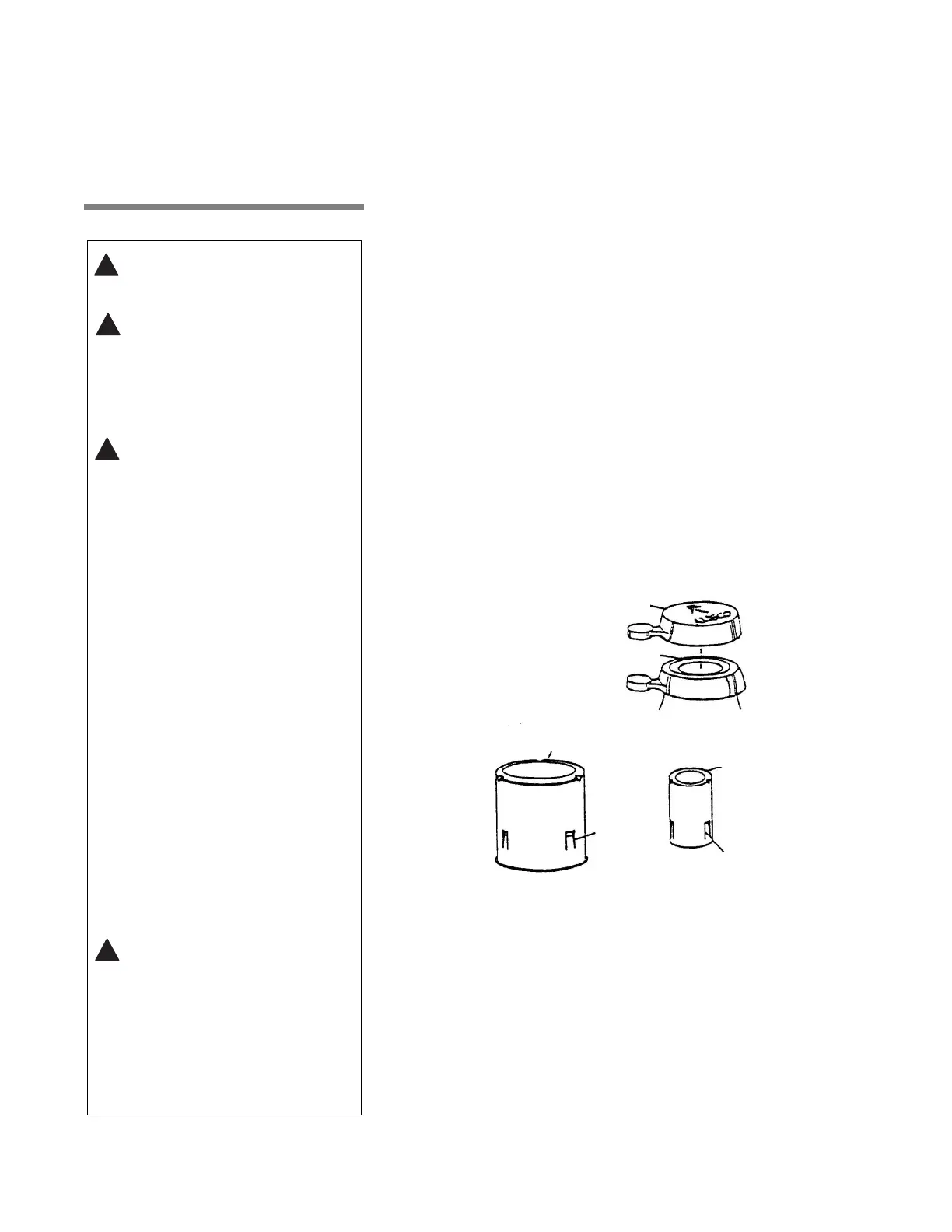

have cooled. Examples of vented closures are shown in F

IGURE 3-1.

When loading the sterilizer, place small bottles in a separate basket

to minimize sliding.

Always use side rails on the loading car to prevent containers or

baskets from falling off.

Figure 3-1. Vented Closures

Before Sterilization

After Sterilization

Morton Closure

Tab

Tab

Morton Closure

Morton Closure

WARNING – EXPLOSION HAZARD:

This sterilizer is not designed to

process flammable compounds.

WARNING – PERSONAL INJURY

HAZARD: Avoid personal injury

from bursting bottles. Liquid

sterilization cycle must only be

used for liquids in borosilicate

(Pyrex) flasks with vented

closures.

WARNING – BURN HAZARD:

• Steam may be released from the

chamber when door is opened.

Step back from the sterilizer each

time the door is opened to

minimize contact with steam

vapor.

• When sterilizing liquids, to prevent

personal injury or property

damage resulting from bursting

bottles and hot fluid, you must

observe the following procedures:

• Use LIQUID cycle only; no

other cycle is safe for

processing liquids.

• Use only vented closures; do

not use screw caps or rubber

stoppers with crimped seal.

• Use only Type 1 borosilicate

glass bottles; do not use

ordinary glass bottles or any

container not designed for

sterilization.

• Do not allow hot bottles to be

jolted; this can cause hot-bottle

explosions. Do not move

bottles if any boiling or

bubbling is present.

CAUTION – POSSIBLE

EQUIPMENT DAMAGE:

Sterilization of chloride-

containing solutions (e.g., saline)

can cause chamber corrosion and

is not recommended by the

manufacturer. If, however,

chloride-containing solutions

must be processed, clean the

chamber after each use.

Loading...

Loading...