SmartROC D65 T4F 9 Angle instruments

136 No: 713944459.6 en

9.1.10 Operation

1.

Move the drill rig to the drill site and set it in the desired position.

2.

Select a reference point and turn the sight so that the arrow points towards the refer-

ence point. The reference point should be as far away as possible (at least 2 km) if it

does not lie in direct line with the row of holes in order to minimise angle error. If the

reference point lies in line with the row of holes, it can be as close as 10 m from the

last hole of the row without any angle errors arising.

3.

Set the desired hole inclination front/back or left/right.

4.

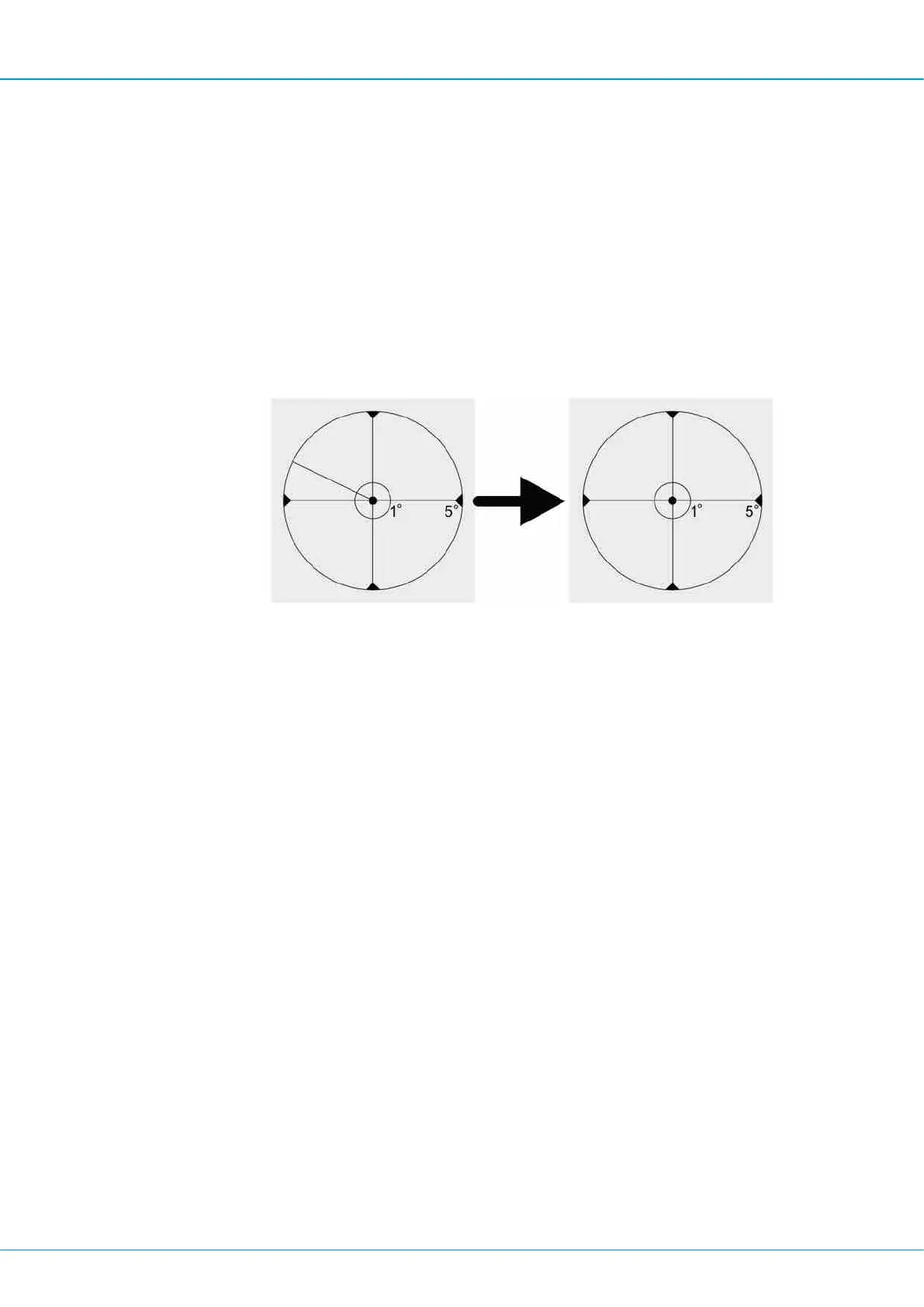

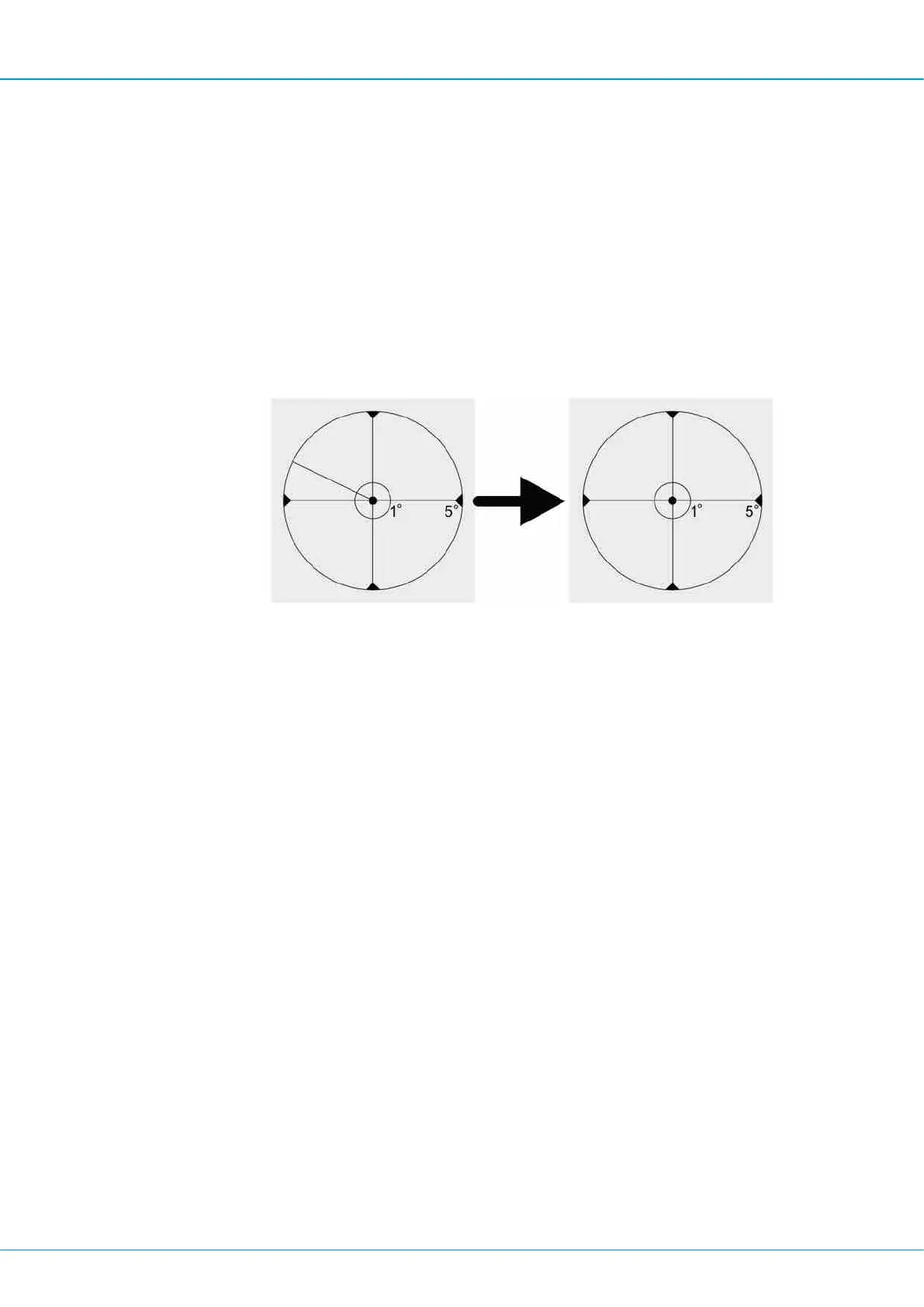

Position the feed beam so that the red line in the graphic is reduced to a red dot in the

centre. Once this has occurred, the desired angle value is the same as the actual

value.

Positioning using the angle instrument.

5.

Press the feeder spike against the ground by using the feed extension.

6.

Set the desired hole length / vertical depth in the hole length instrument's menu if

automatic drill stop is to be used.

7.

Place the drill bit on the ground and reset the length measurement with F1 or F4. This

reset should be done even if the laser plane function is used.

8.

Drill until the preset depth has been reached and drilling stops automatically or drill

until the desired drilled length is shown in the drilled length menu and switch off

drilling manually.

9.

Pull up the drill rod and move the drill rig to the next hole or turn the boom to the next

hole if it has sufficient reach.

10.

If the rig is moved, the aim device should be turned until it is aligned with the refer-

ence point. The instrument will then take the rig's new position into consideration to

make the next hole parallel to the previous one. If additional holes can be drilled

without changing the set-up, the aim device does not have to be adjusted.

11.

Repeat steps 4-10.

Loading...

Loading...