SmartROC D65 T4F 4 Daily checks

34 No: 713944459.6 en

4.4 Functionality test after start

4.4.1 Checks

!

NOTE: The emergency stop buttons and wires must be checked before each shift and

after tramming.

Check point Inspection Instructions

Emergency stop buttons (all) and

the emergency stop wire on the

feed beam.

Function Check each emergency stop

button individually. The diesel

engine must stop!

Between testing each emer-

gency stop, the previous stop

must be reset before restarting

the rig. For the location of the

stops, see "Safety"

Display for engine and directional

instruments

Visual check Check that none of the fault in-

dicator symbols is on. If a fault is

indicated in the status bar, stop

the unit and rectify the fault.

Table9: Checks.

4.5 Function test while drilling

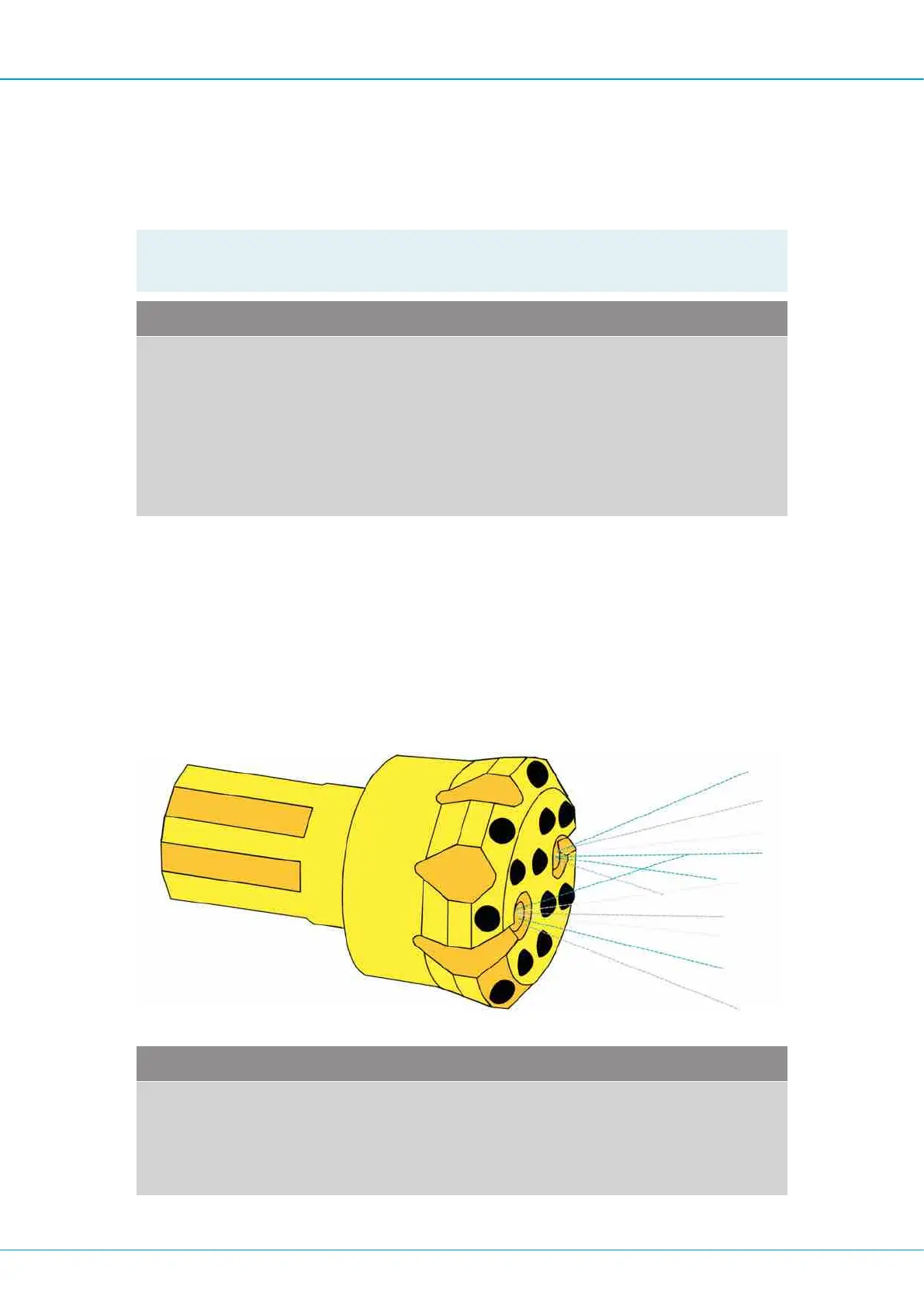

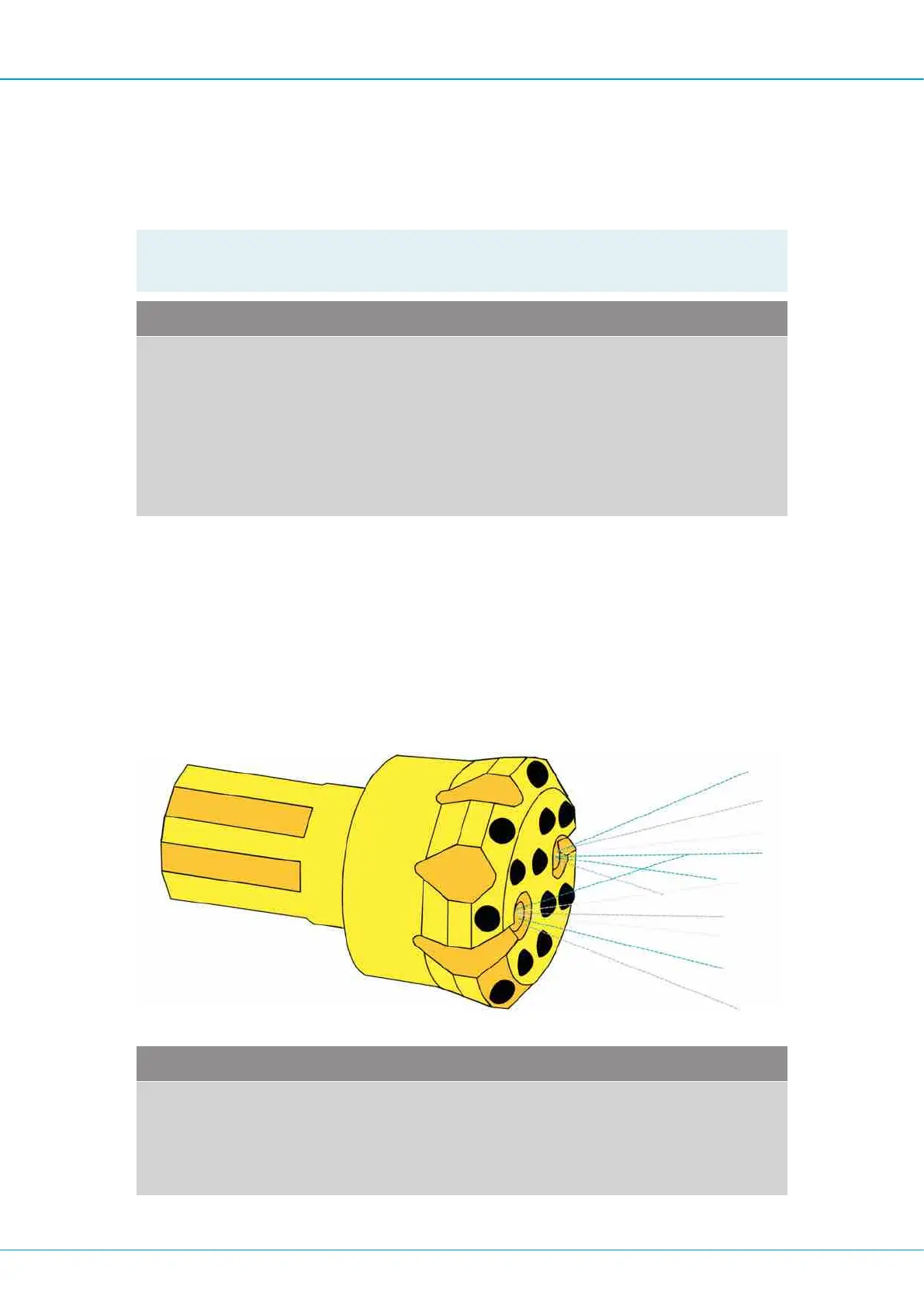

4.5.1 Down-the-hole rock drill (DTH)

The down-the-hole rock drill's drill bit

Check point Inspection Instructions

Down-the-hole rock drill (DTH) Function Lubrication oil should seep out

of the drill bit. Place a plank in

front of the drill bit and activate

air flushing. The plank should

become oily after a short time.

Table10: Down-the-hole rock drill.

Loading...

Loading...