SmartROC D65 T4F 10 Options

172 No: 713944459.6 en

Description Data

Ripple in relation to voltage 5% acc. as per DIN 41755

10.5 Thread lubrication

10.5.1 General

Function

Drill pipe threads are lubricated by means of spraying grease on them through a nozzle

which is located on the upper breakout table.

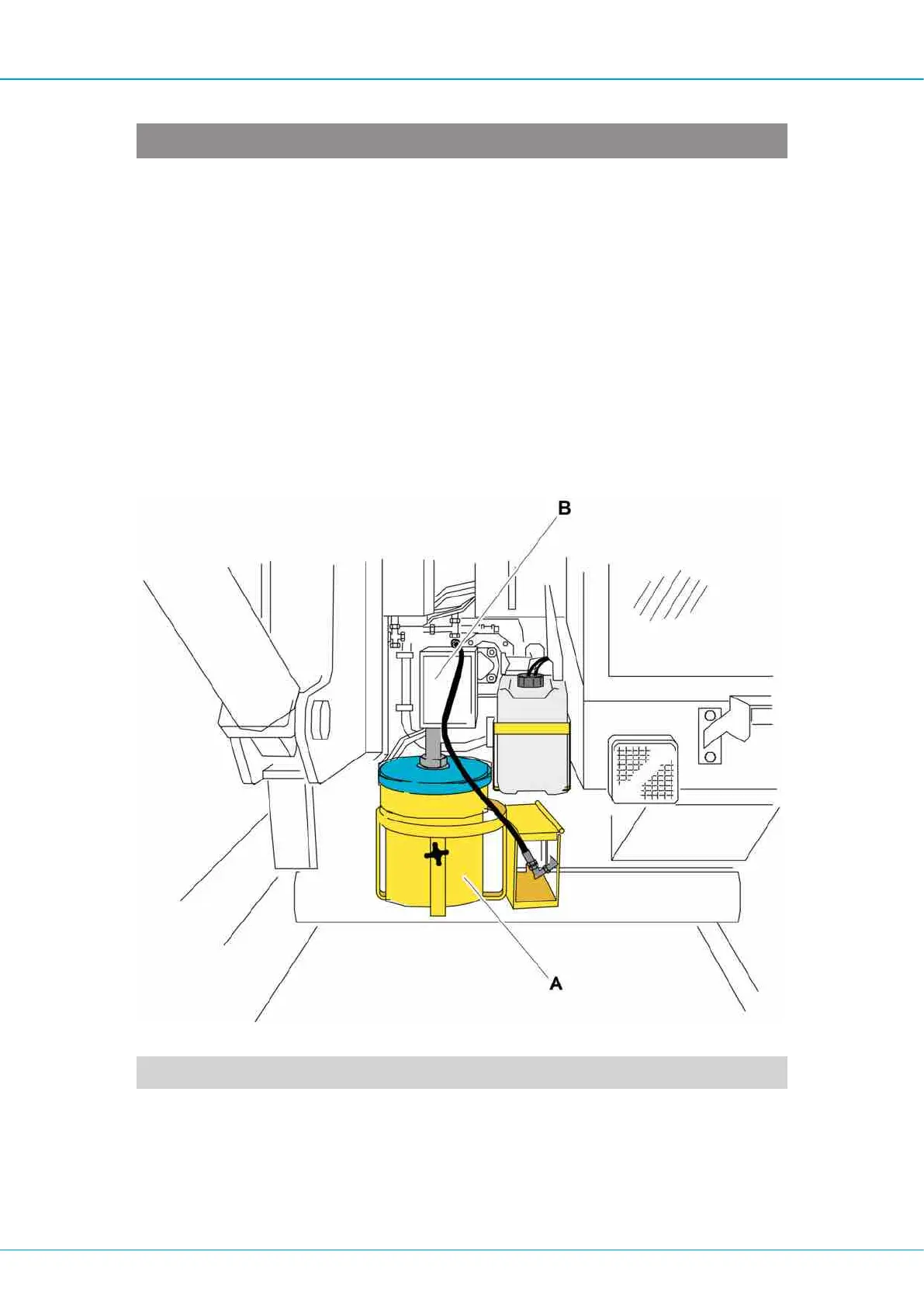

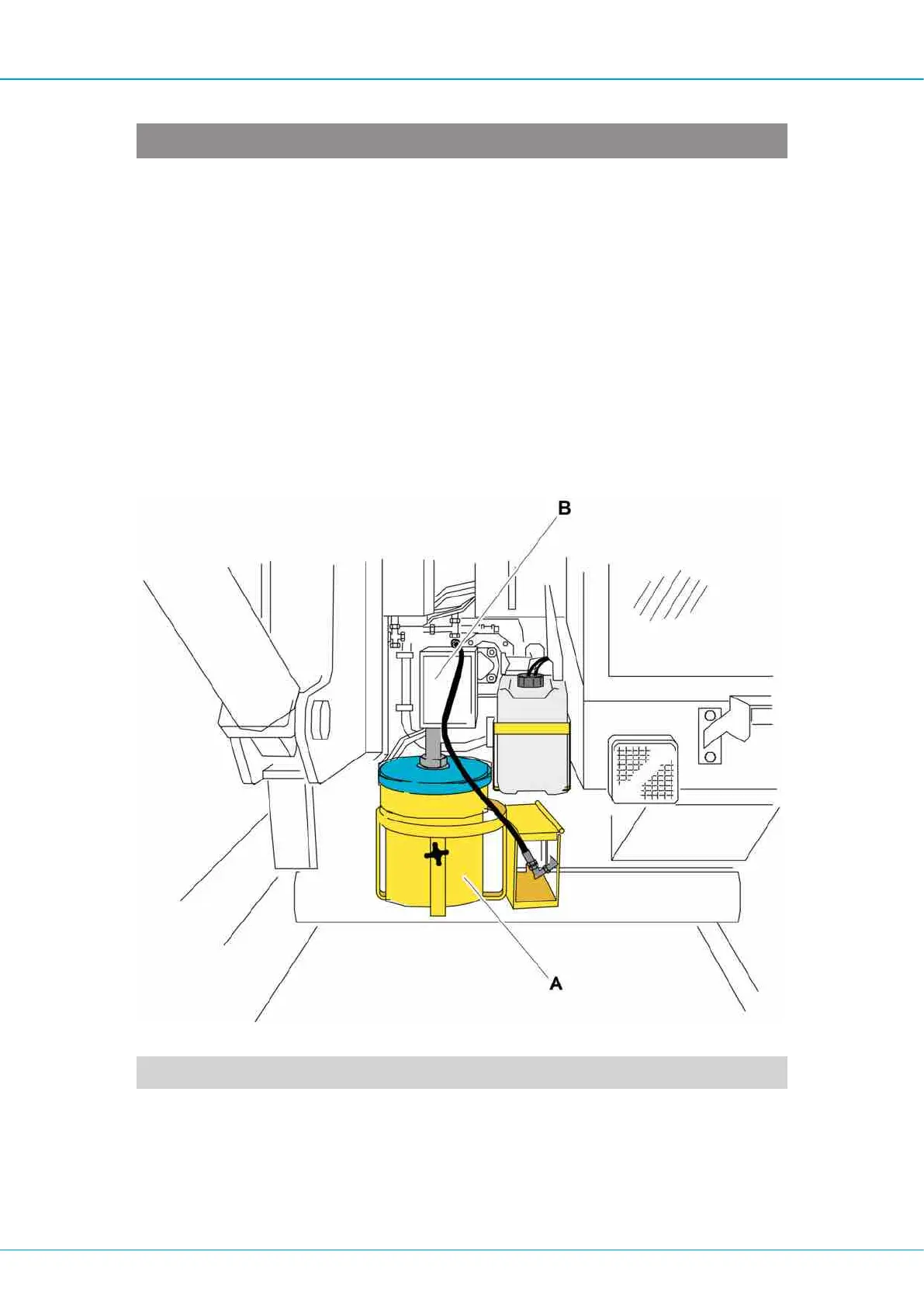

The grease comes from a compressed air powered pump (B) which is located in a grease

container (A) on the front of the chassis frame. Grease is pumped from the grease con-

tainer to the nozzle where it is sprayed on the thread using compressed air from a separate

air line to the nozzle.

Thread lubrication system.

A Grease tank

B Pump

Operation and adjustment

The direction of the nozzle must be adjusted so that the grease reaches the male thread

when a pipe is in breakout position.

Loading...

Loading...