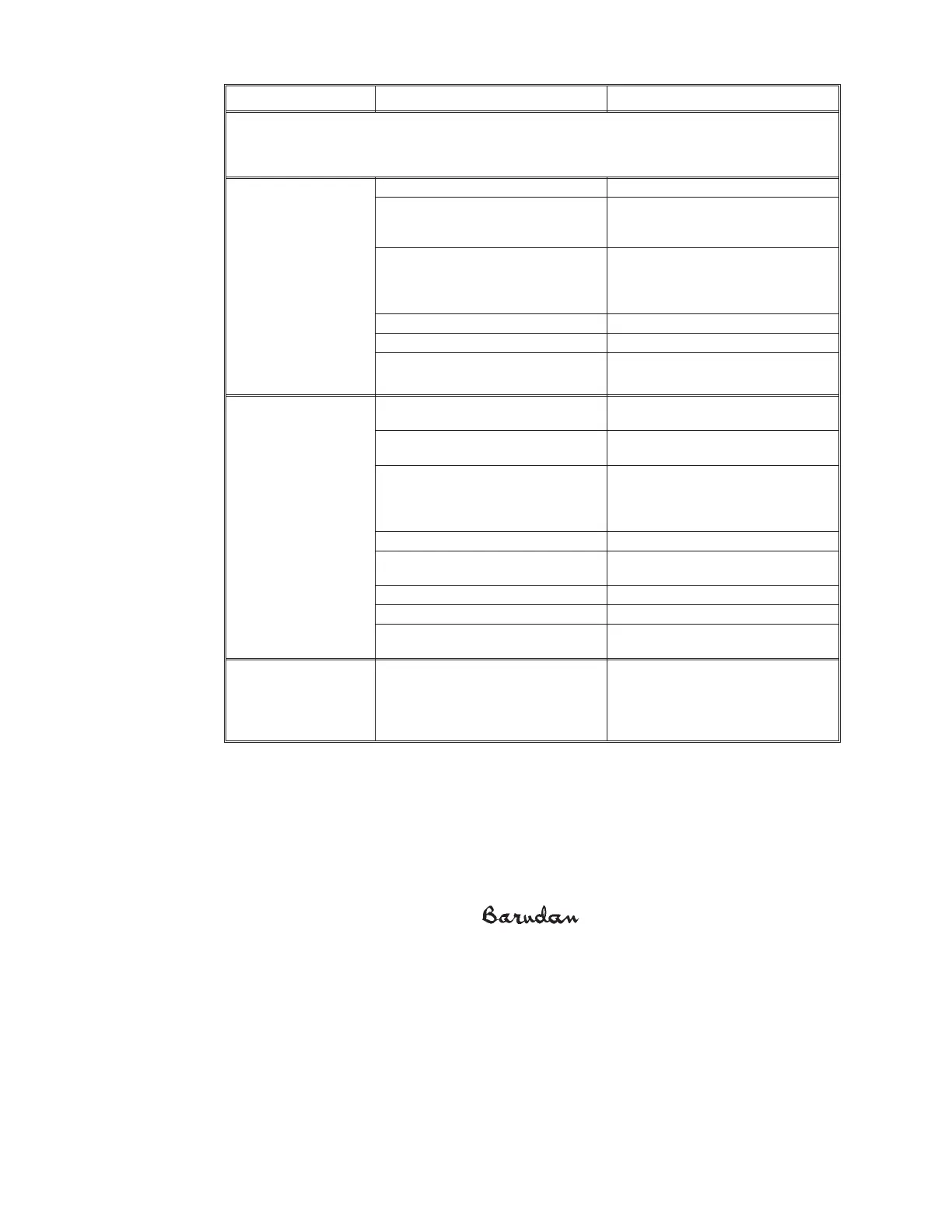

PROBLEM CAUSE SOLUTION

NOTE: Whenever you break a needle, make sure you find all parts of it before you continue sewing. A

needle point that gets lodged in the hook assembly of the machine can cause the machine to bind up and

stop running, possibly causing serious damage. Also check for burrs on the hook if parts of the needle are

found under the needle plate.

Stitches Are Not Being

Formed

Bobbin is empty Replace with full bobbin.

Not enough bobbin thread pulled out

of bobbin case

There should be at least three (3)

inches of thread hanging from the

bobbin case when it is replaced.

Needle inserted improperly Make sure the needle is inserted all

the way into the needle bar and the

long groove is in front. Make sure the

needle clamp crew is tight.

Timing is off Re-time the hook.

Broken hook point Replace the entire hook assembly.

Thread is not threaded through the

take-up lever.

Check all threading points to make

sure none have been missed.

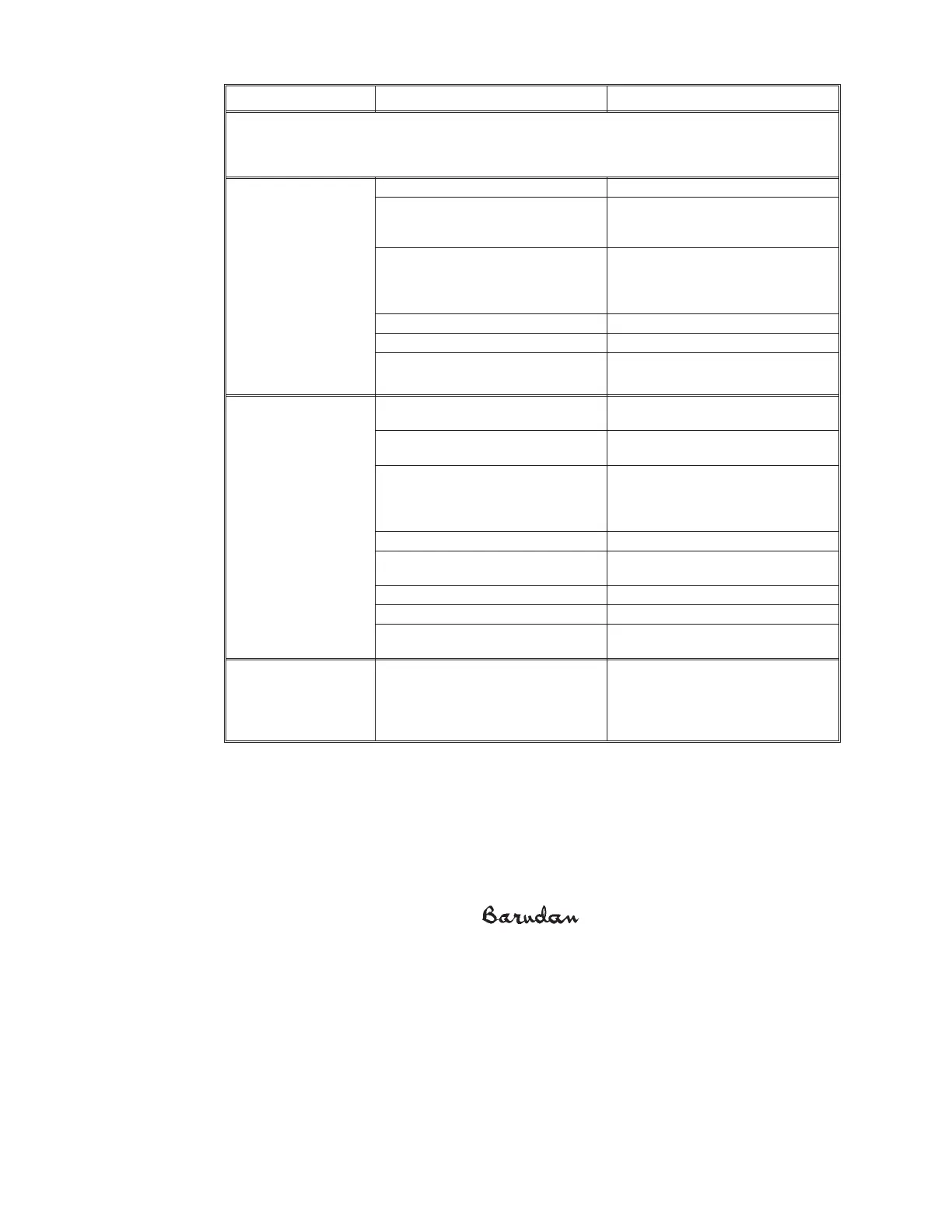

Thread “Birdnests”

Under Needle Plate

Area

Improper threading Check all threading points to make

sure none have been missed.

Hooped too loosely Fabric must be hooped securely, with

proper backing.

Lack of lubrication in hook assembly.

Even if you oil the machine every

day, this can happen when you run

the machine especially long and hard.

Place one drop of oil in hook assem-

bly oiling point.

Using a fill stitch on very small areas Change to a satin stitch.

Tension problems Adjust the tension. Remove the bob-

bin case and check the tension.

Faulty take-up spring Replace the take-up spring.

Dull needle Replace the needle.

Needle is too large, making hole in

fabric

Change to a smaller needle.

Thread Breaks Flow of top thread is obstructed Check the top tension, if it is too

tight, see if the thread is caught on the

tension disks, thread stand or thread

spool pin and make sure it is not

looped around the take-up spring.

3-2 X Series Mechanical Guide

Loading...

Loading...