4.

Rotate theMain Drive Pulley to wheretheindicatorpointto 24 degrees(Arm type

heads)25 degrees(Bridge typeheads). The pointof thehook shouldbe directly

behindthescarf of theneedleandabovetheneedleeye.

5. Check thehook-to-needleclearance.There should

be approximately½ of a needles-widthclearance

betweenthehook pointandtheback of theneedle.

Improperadjustmentwould causethehook pointto

miss thesmall loop andcreatea skippedstitch.

6. Replace thecovers.

Adjusting the Hook Timing

1. Clean any threaddebrisor lint from thehook area

with compressedair.

2. Loosen thethreescrews at therear baseof thehook.

This will allow you to advanceor retardthehook.

3. Locate themain drive pulley with degreeindicator.

X Series Mechanical Guide 3-6

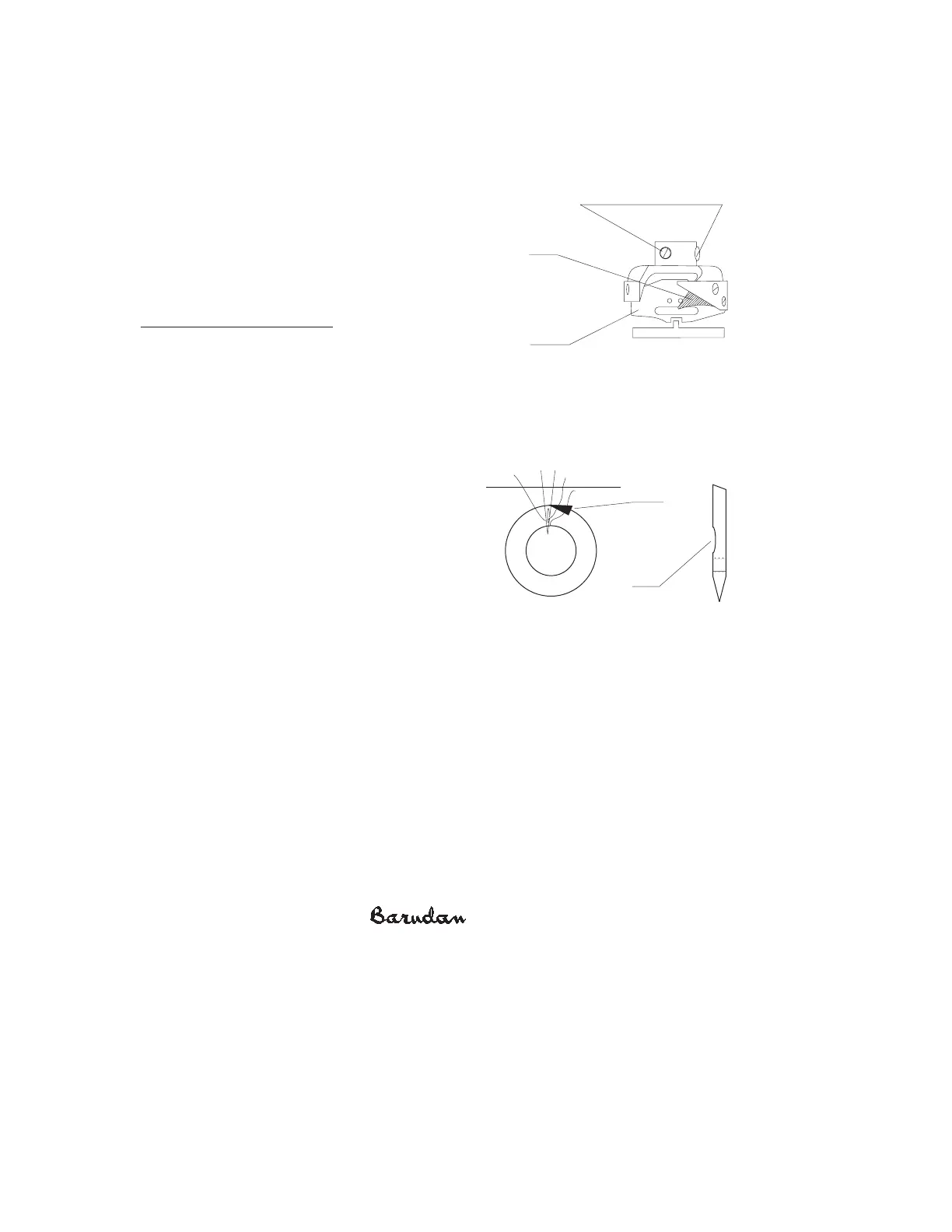

Basket

Hook AssemblyHook Assembly

Hook

Point

Adjustment Screws

(third screw not shown)

Adjustment Screws

(third screw not shown)

4. Rotate themain drive pulley to wherethe

indicatorpointsto thenecessarydegree.The

pointof thehook shouldbe directly behind

thescarf of theneedleandabovetheneedle

eye.

5. Check thehook-to-needleclearance.There

shouldbe approximately ½ a needles-width

clearancebetweenthehook pointandthe

back of theneedle.Improperadjustmentwould causethehook pointto miss the

small loop andcreatea skippedstitch.

6. When thecorrectpositionhas beenattained,tightenthethreescrews on thehook.

7. Adjust thePosition Finger Bracket (see thenext page).

• An H or I testis an excellentmannerof testingthehook timing

adjustments.Sew out theseletters(one for eachneedle)andcheck for any

irregularities in thesewingandstitch quality. Thread breaks, needle

breaksor skippedstitchescan occur whenthehook is notproperlytimed.

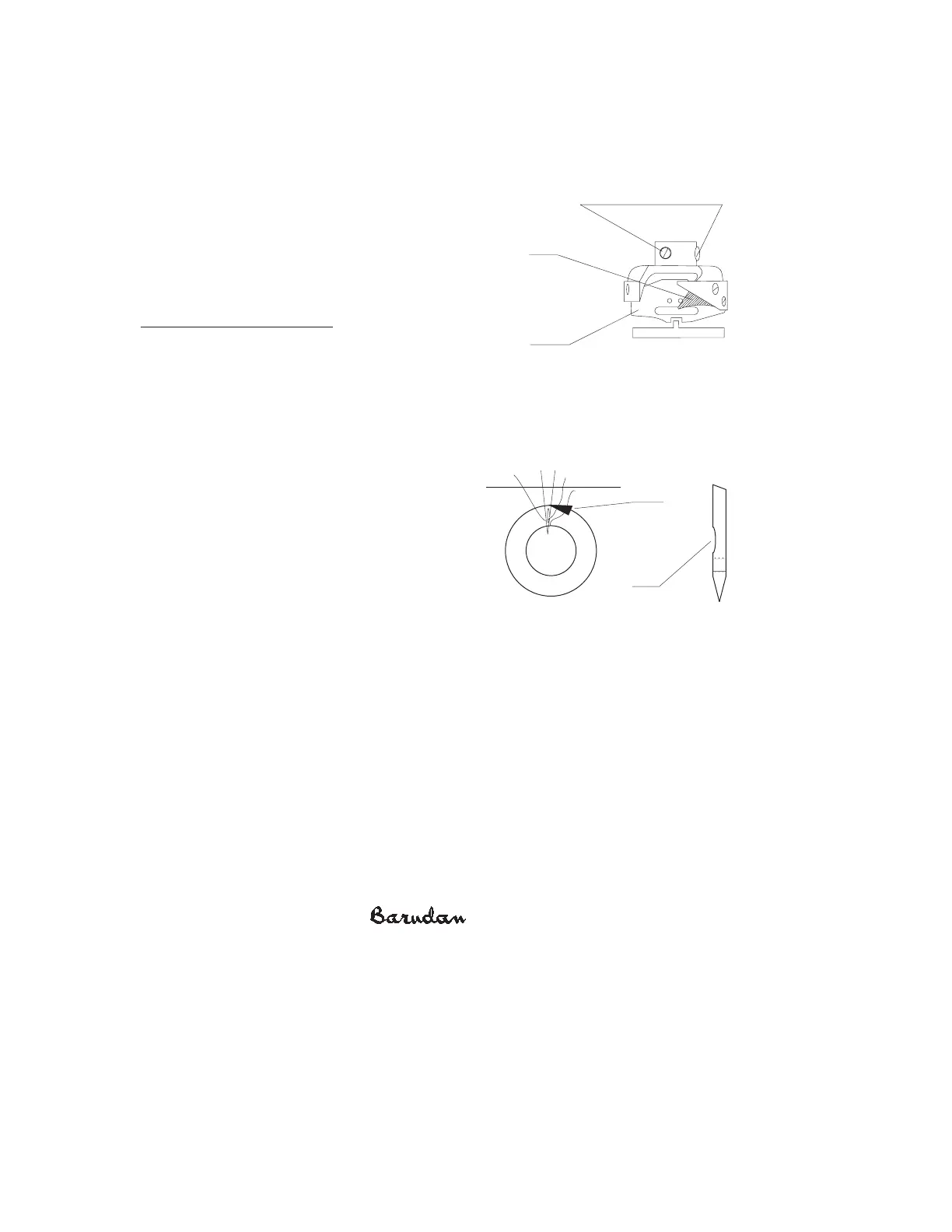

Hook

Point

Hook

Point

Scarf

Loading...

Loading...