SENSseries LB 480 Level measurement

BERTHOLD TECHNOLOGIES GmbH & Co. KG

2 – 237

Volume 2 4 Repair, Maintenance and Upkeep

2

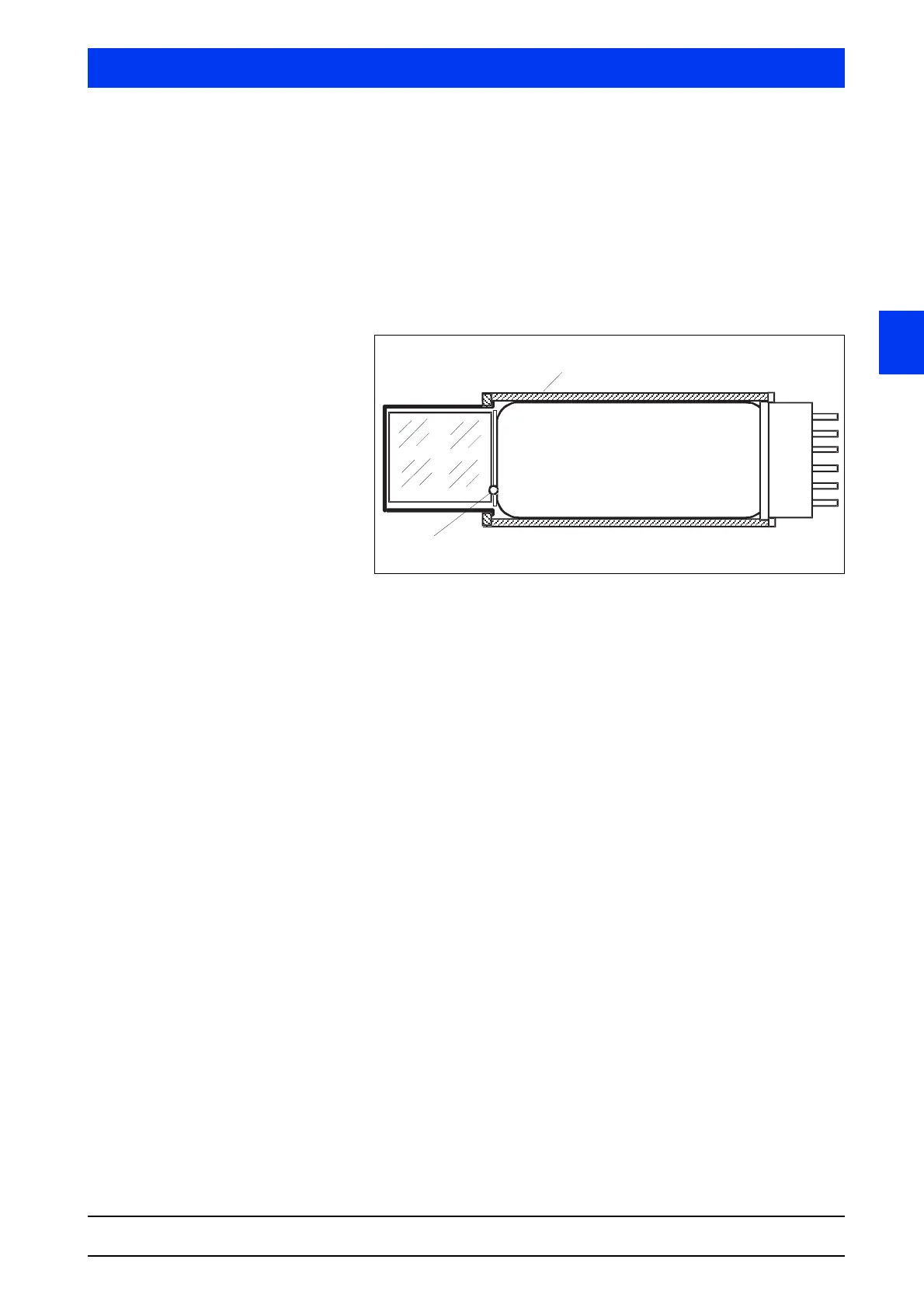

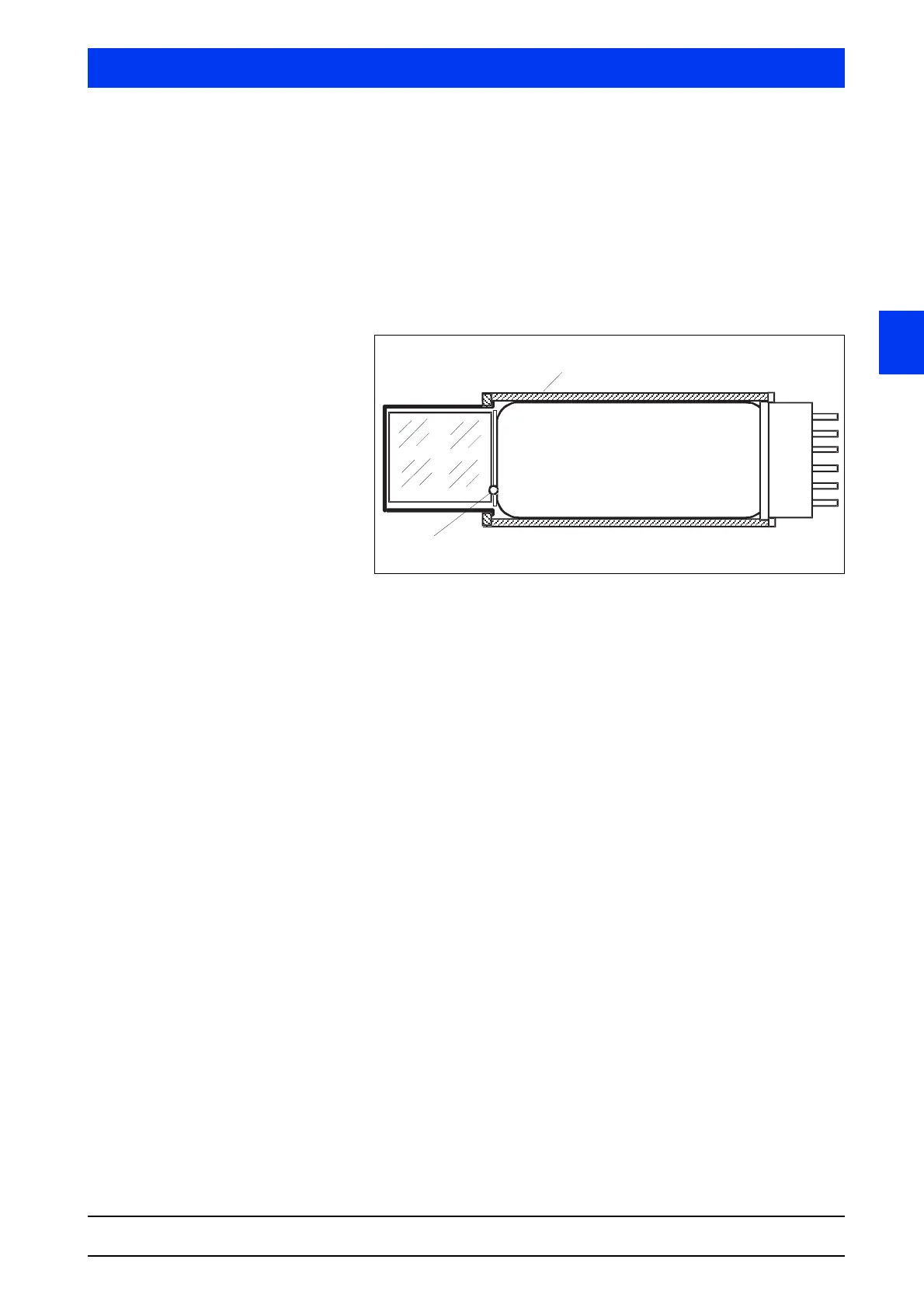

4.5.2 Checking the Crystal-Multiplier Assembly

The plateau becoming too small or too steep indicates faults in the

crystal-multiplier assembly. They can often be detected through

visual inspection. To do this, take the crystal-multiplier assembly

apart. To separate both parts, remove the Mu metal shielding and

carefully detach the crystal from the multiplier window by gently

sliding the crystal sideways. Wipe silicon oil traces off the mating

faces of crystal and multiplier using a soft cloth. While you are doing

this, make sure that the multiplier is not exposed to bright sunlight.

Fig. 4-4 Crystal-multiplier assembly

The crystal must be perfectly clear inside and not show any cracks

or dull areas. The normal coloring is slightly greenish. A yellowish

to brownish coloring is a sign of thermal overload and indicates that

the crystal must be replaced.

The multiplier window is coated with a vapor-deposited layer acting

as photo cathode. This layer gives the window a brownish tint sim-

ilar to smoked glass. If this layer is no longer present or if it is

stained, then the photo-cathode has been destroyed (e.g. by over-

heating, glass breakage, or incident light). The multiplier must be

replaced. Faults caused by damage to the dynode systems (e.g. by

excessive vibration) cannot be identified by appearance. If in doubt,

replace the multiplier.

Before re-assembly, apply a drop of pure silicon oil (Berthold Id.-Nr.

18844) between crystal and multiplier, and distribute it evenly by

gentle rubbing to ensure a sound optical connection between the

two components. Using the adhesive tape, replace the Mu-metal

screen, making sure that it is only under light tension.

Magnetic shielding (Mu metal)

Optical connection

Multiplier

Crystal

Loading...

Loading...