54733-10BA2L

2 – 180 02.2017

2 Installation Volume 2

2.4 Detector Assembly

Make sure that

– the detector or the source fixtures do not obstruct the beam

path.

– there are no pipes, flanges, stirrers or other installations in the

beam path.

Only installations that have already been taken into account in plan-

ning the measurement configuration are permitted. Otherwise, the

curve is no longer linear; there may even be sections in the mea-

surement range where the measured values do not change.

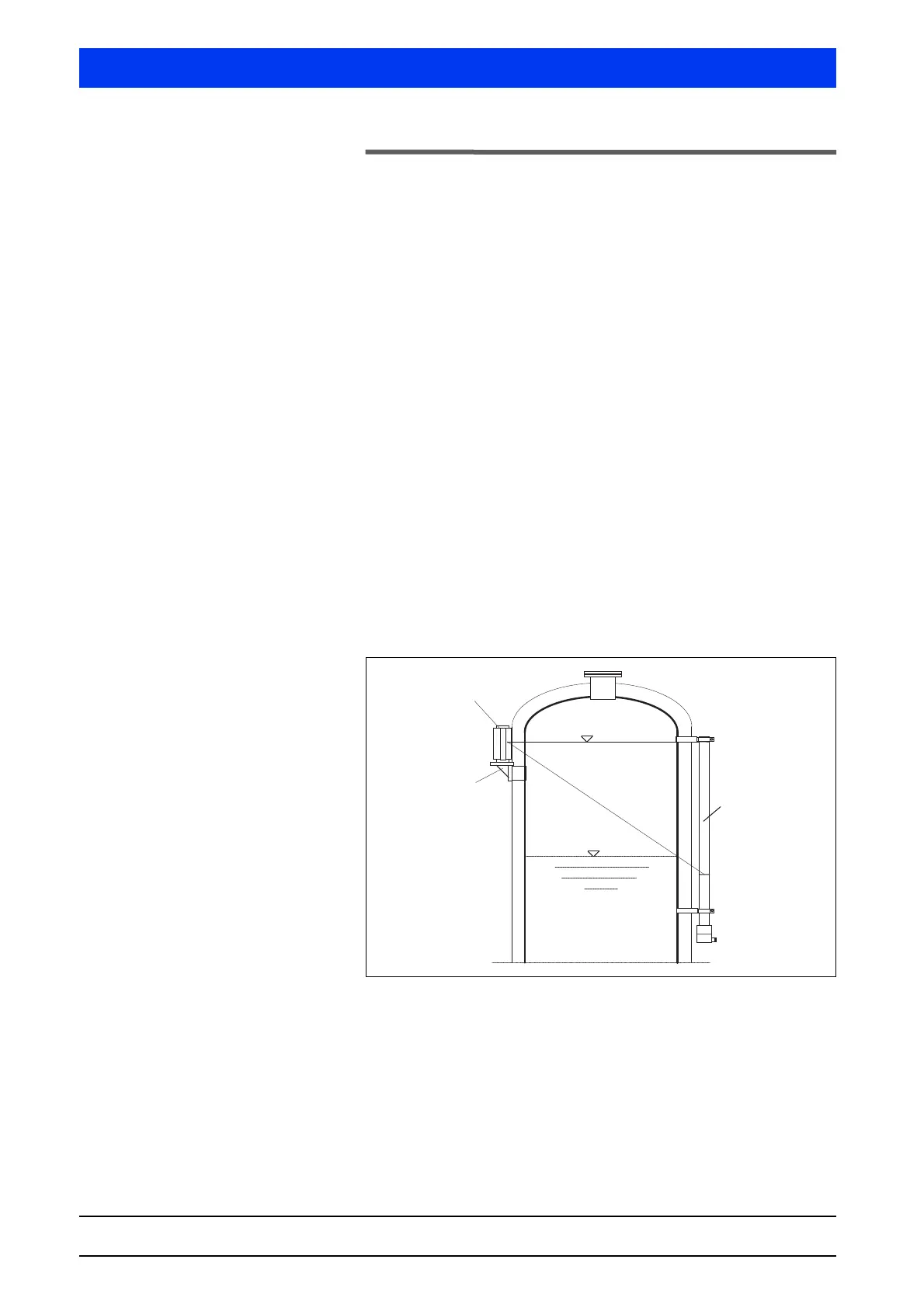

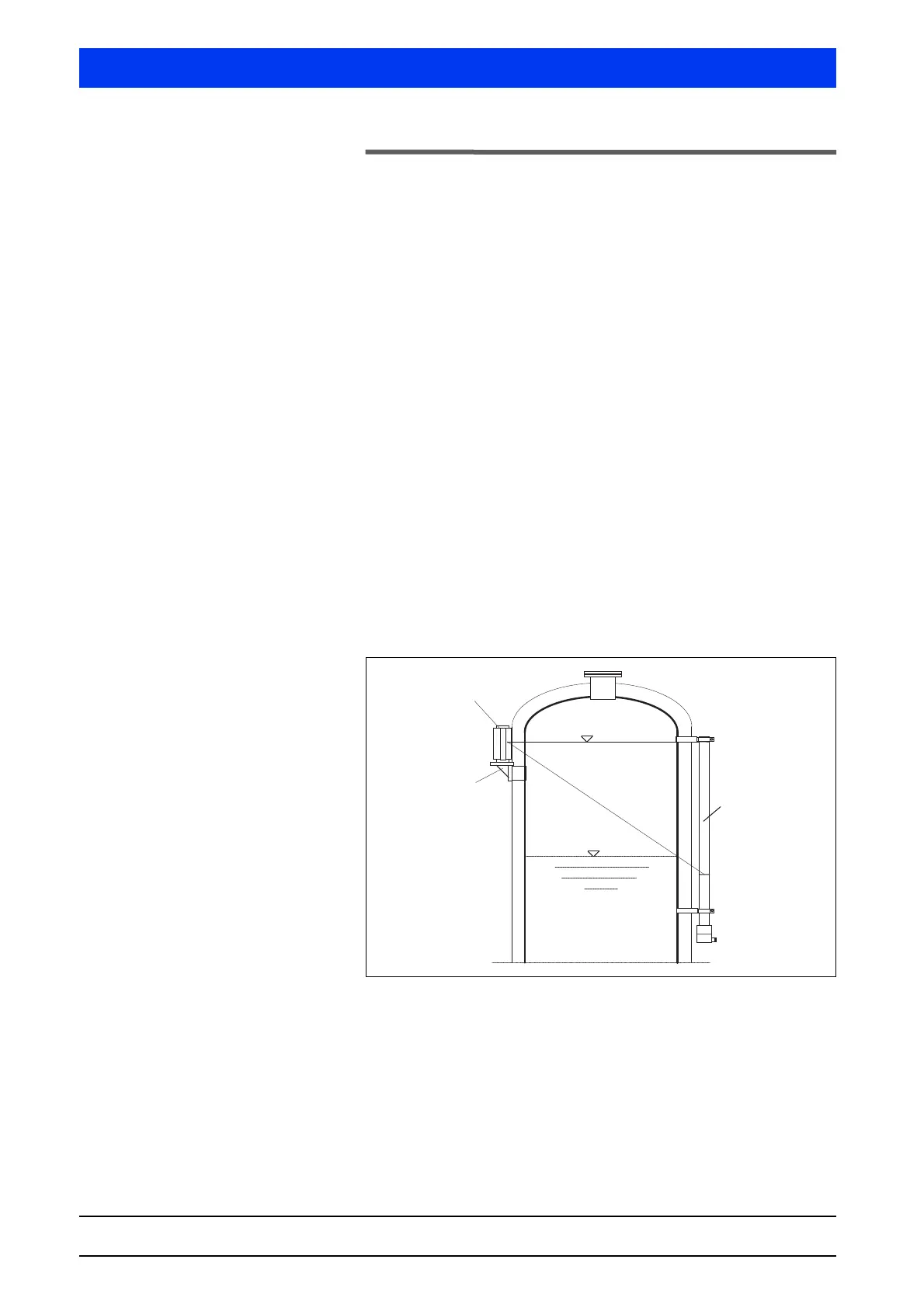

2.4.1 Rod Detector with and without Water Cooling

The rod detector is mounted vertically on the outside of the vessel.

The top point of the effective detector length is marked by a mark-

ing groove, which also defines the top point of the measuring range

that can be covered. Please note the dimensional drawings of the

rod detector (page 2-243).

As shown in Fig. 2-2, the rod detector is mounted outside the

marking grooves, with one fixing clamp each at the top and at the

bottom. The distance from the center of the detector to the surface

of the vessel or the surface of a thermal insulation is about 100

mm. The clamps have to be arranged so that no heat is transferred

to the detector.

Fig. 2-2 Rod detector installation, example with point source

Max

Min

Support

Montagesockel

Point Source Shielding

Punktstrahler-Abschirmung

Rod Detector

Stabdetektor

←

Marking Groove

Markierungsrille

←

Marking Groove

Markierungsrille

Loading...

Loading...