SENSseries LB 480 Level measurement

BERTHOLD TECHNOLOGIES GmbH & Co. KG

3 – 417

Volume 3 7 Explanations

3

7.4 Multi-point calibration

Polygon line When should a polygon calibration be conducted?

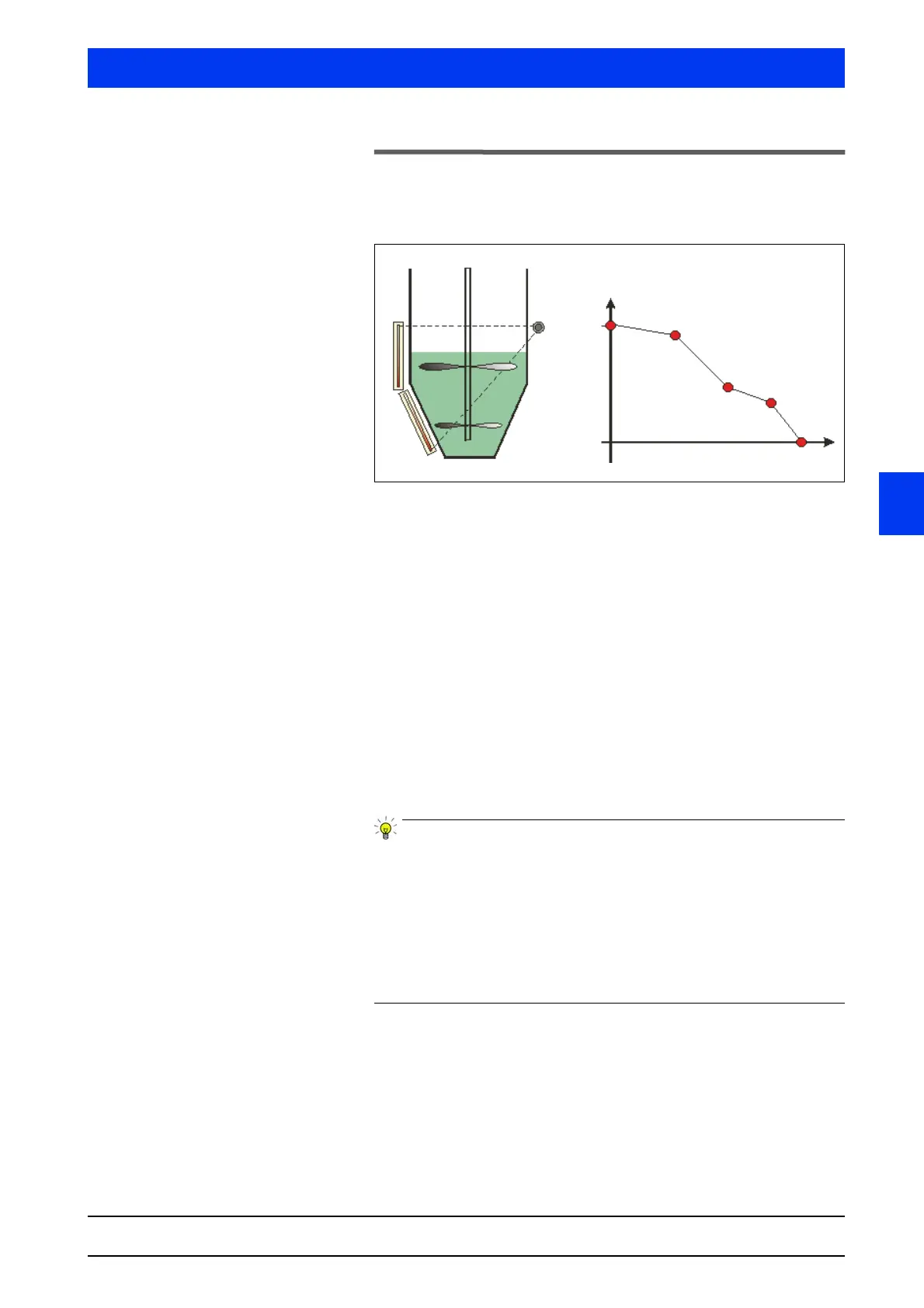

Fig. 7-8 Multi-point calibration

A polygon calibration makes sense:

• if high precision is called for

• on irregular container shapes such as conical or lying cylindrical

vessel

• if accessories such, e.g. an agitator, are in the radiation path.

As a rule, the container is filled in steps of 5 to 10 different levels.

With the values measured in this way, the SENSseries can be

adjusted.

If it is not possible to fill the different levels with the product, you

may also use one product which is equal in density. Often water is

used as replacement for the product. Please contact our field ser-

vice staff, or BERTHOLD TECHNOLOGIES directly to get more infor-

mation on optimum calibration.

Try to record as many value pairs as possible, but use as few value

pairs as possible for calibration. A few calibration points can be

handled and controlled more easily than a lot of calibration points.

This also reduces the risk of input errors.

If you have measured several calibration points it is quite helpful to

draw the calibration curve. Using the curve it is easy to tell which

calibration points are not necessary, i.e. those that fall between

calibration points already in a flat line.

Loading...

Loading...