SENSseries LB 480

BERTHOLD TECHNOLOGIES GmbH & Co. KG

1 – 51

Volume 1 5 Explosion Protection

1

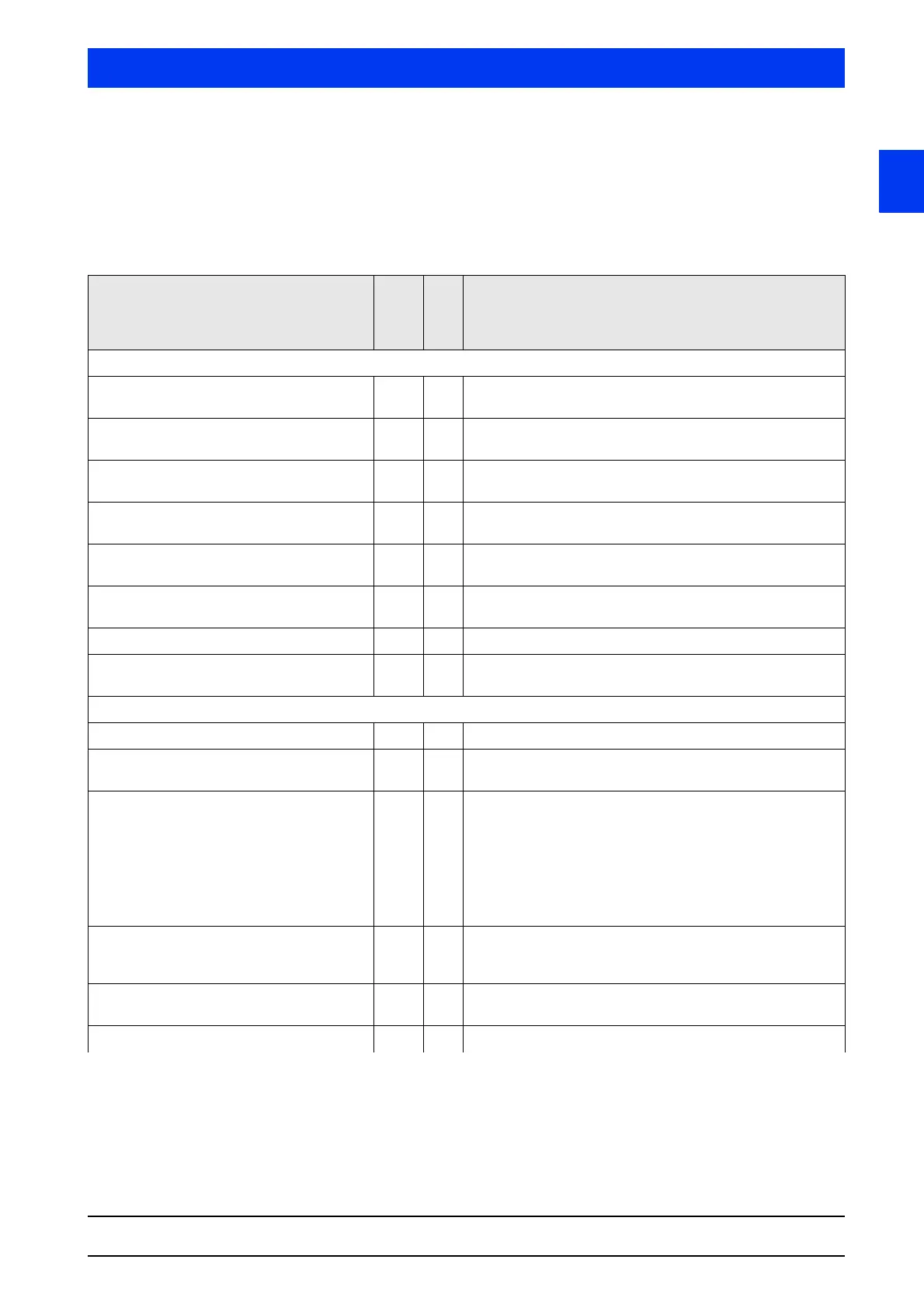

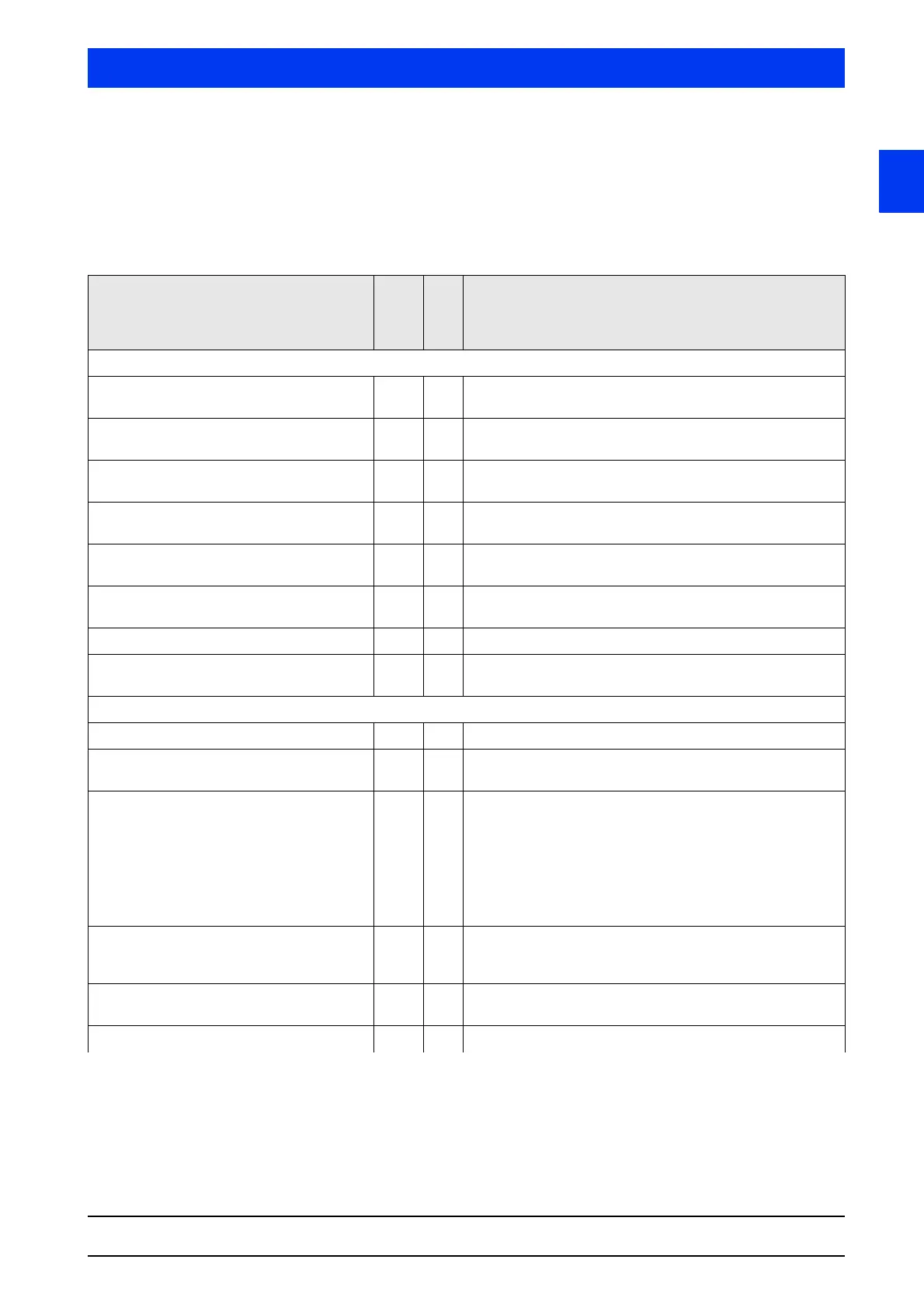

5.8.1 Plan for Visual Inspection of the Detector

If you answer one of the following questions with "No", you have to

record the action you have taken to remedy this deficiency in the

last column. Make sure before you take the device into operation

again that the provisions you have taken are correct by consulting

with the person in charge of explosion protection.

Date: ...............................................

Name:.................................................

Yes No Measures

General test

Is the housing free of corrosion, dents,

cracks, holes and warps?

Is the housing cover of the detector firmly

attached?

Are the permissible functional and

safety-related temperatures observed?

Are the external connections of the poten-

tial equalizer in good working order?

Is the surface of the detector free of contact

with other non-alloy steel parts?

Are the connected cables installed

strain-relieved?

Is a separator in place?

Is the separator easily accessible for main-

tenance personnel?

Test of screwed fittings (cable glands, adapters, sealing plugs)

Were only metallic fittings used?

Are the screwed fittings suitable for the

ambient conditions?

Are screwed fittings used for the normal

ambient temperature range between -20° C

and +40° C that at least meet the stan-

dards specified on the cover page of the EC

type-examination certificate or are screwed

fittings used that have been approved for

use in the LB 480 by BERTHOLD

TECHNOLOGIES?

Is the permissible temperature range of the

screwed fittings suitable for the tempera-

tures encountered?

Are the screwed fittings suitable for the

required protection type (at least IP 65)?

Are the screwed fittings free of corrosion?

Loading...

Loading...