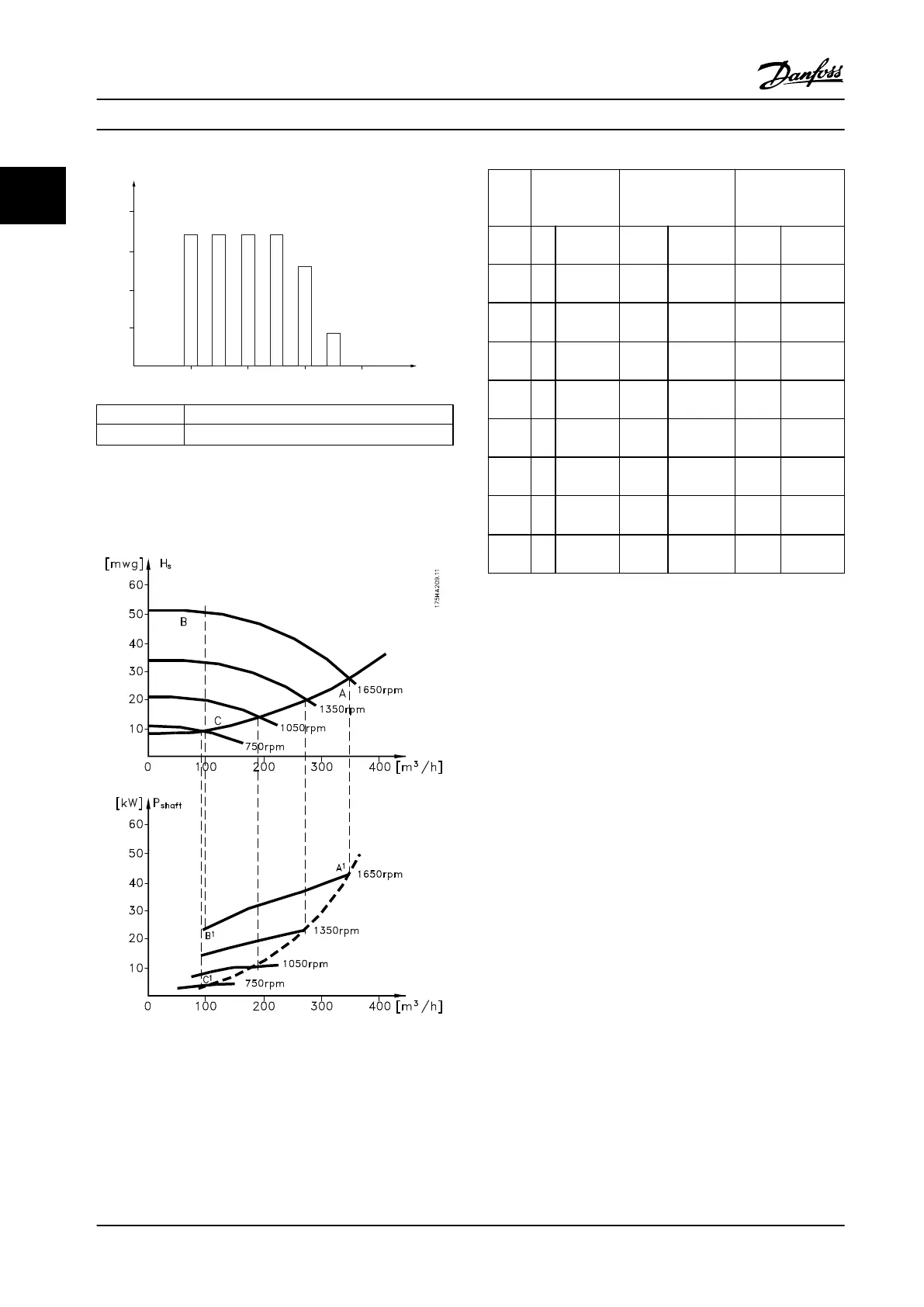

500

[h]

t

1000

1500

2000

200100 300

[m

3

/h]

400

Q

175HA210.11

t [h]

Duration of ow. See also Table 2.2.

Q [m

3

/h]

Flow rate

Figure 2.6 Flow Distribution over 1 Year (Duration versus Flow

Rate)

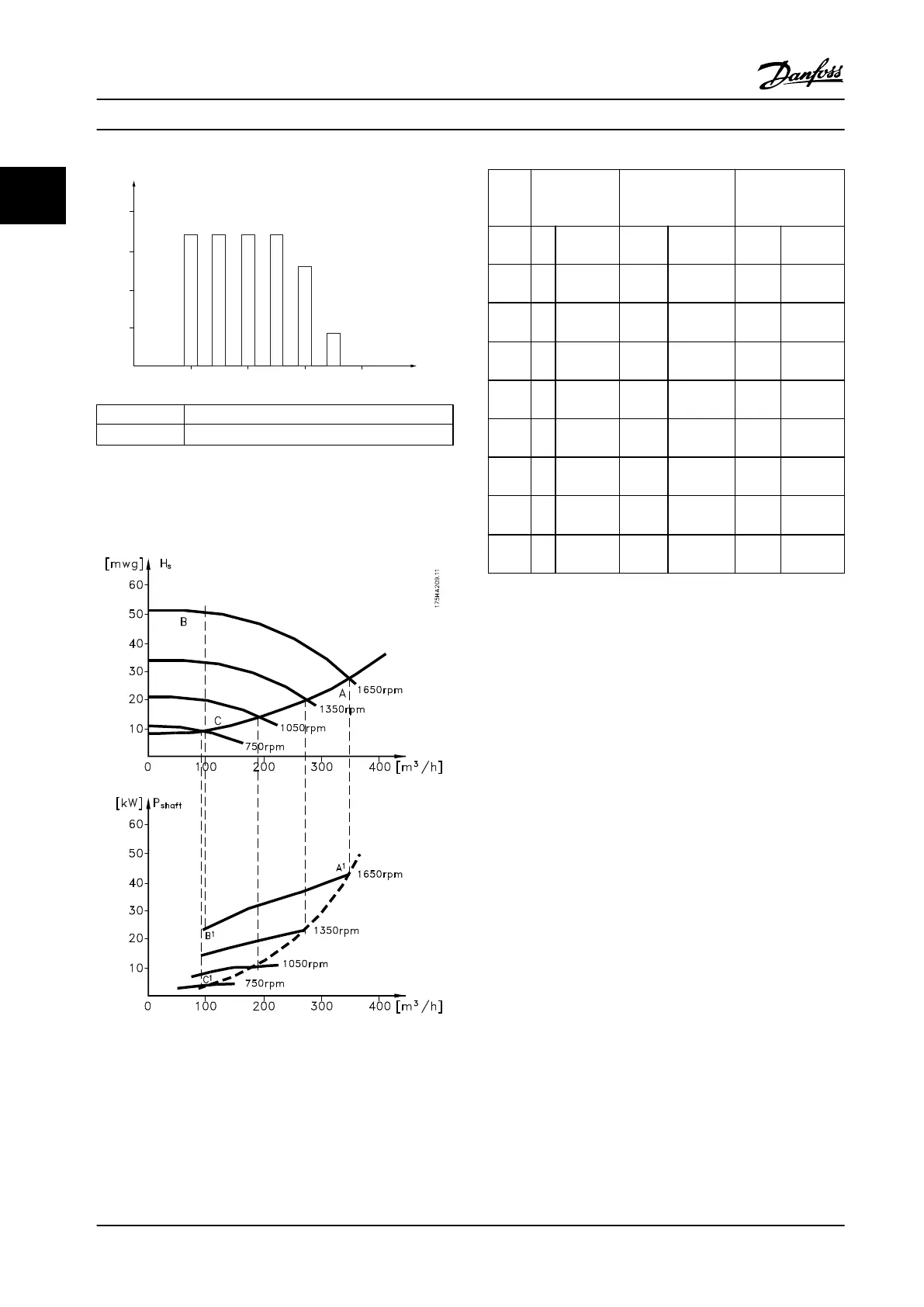

Figure 2.7 Energy Consumption at Dierent Speeds

Flow

rate

Distribution Valve regulation Adjustable

frequency drive

control

% Duration Power Consump-

tion

Power Consump-

tion

[m

3

/h]

[h] [kW

(hp)]

[kWh] [kW

(hp)]

[kWh]

350 5 438 42.5

(57)

1)

18.615 42.5

(57)

1)

18.615

300 15 1314 38.5

(52)

50.589 29.0

(39)

38.106

250 20 1752 35.0

(47)

61.320 25

(18.5)

32.412

200 20 1752 42

(31.5)

55.188 11.5

(15.5)

20.148

150 20 1752 28.0

(37.5)

49.056 6.5

(8.7)

11.388

100 20 1752 23.0

(31)

2)

40.296 3.5

(4.7)

3)

6.132

Σ

10

0

8760 – 275.064 – 26.801

Table 2.2 Result

1) Power reading at point A1

2) Power reading at point B1

3) Power reading at point C1

2.1.6

Improved Control

Using an adjustable frequency drive to control the ow or

pressure of a system improves control.

An adjustable frequency drive can vary the speed of the

fan or pump, obtaining variable control of ow and

pressure.

Furthermore, an adjustable frequency drive can quickly

adapt the speed of the fan or pump to new ow or

pressure conditions in the system.

Obtain simple control of process (ow, level, or pressure)

utilizing the built-in PI control.

2.1.7

Star/Delta Starter or Soft Starter

When large motors are started, it is necessary in many

countries to use equipment that limits the start-up current.

In more traditional systems, a star/delta starter or soft

starter is widely used. Such motor starters are not required

if an adjustable frequency drive is used.

As illustrated in Figure 2.8, an adjustable frequency drive

does not consume more than rated current.

Product Overview

VLT

®

AQUA Drive FC 202

18 Danfoss A/S © 09/2014 All rights reserved. MG20N622

22

Loading...

Loading...