The LCP indicates (with a wrench-icon and an “M”) when it is time for a Preventive Maintenance Action, and can be programmed to be indicated on a

digital output in parameter group 5-3*. The Preventive Maintenance Status may be read in par. 16-96

Maintenance Word

. A Preventive Maintenance

indication can be reset from a digital input, the FC bus or manually from the LCP through par. 23-15

Reset Maintenance Word

.

A Maintenance Log with the latest 10 loggings can be read from parameter group 18-0* and via the Alarm log button on the LCP after selecting Maintenance

Log.

NB!

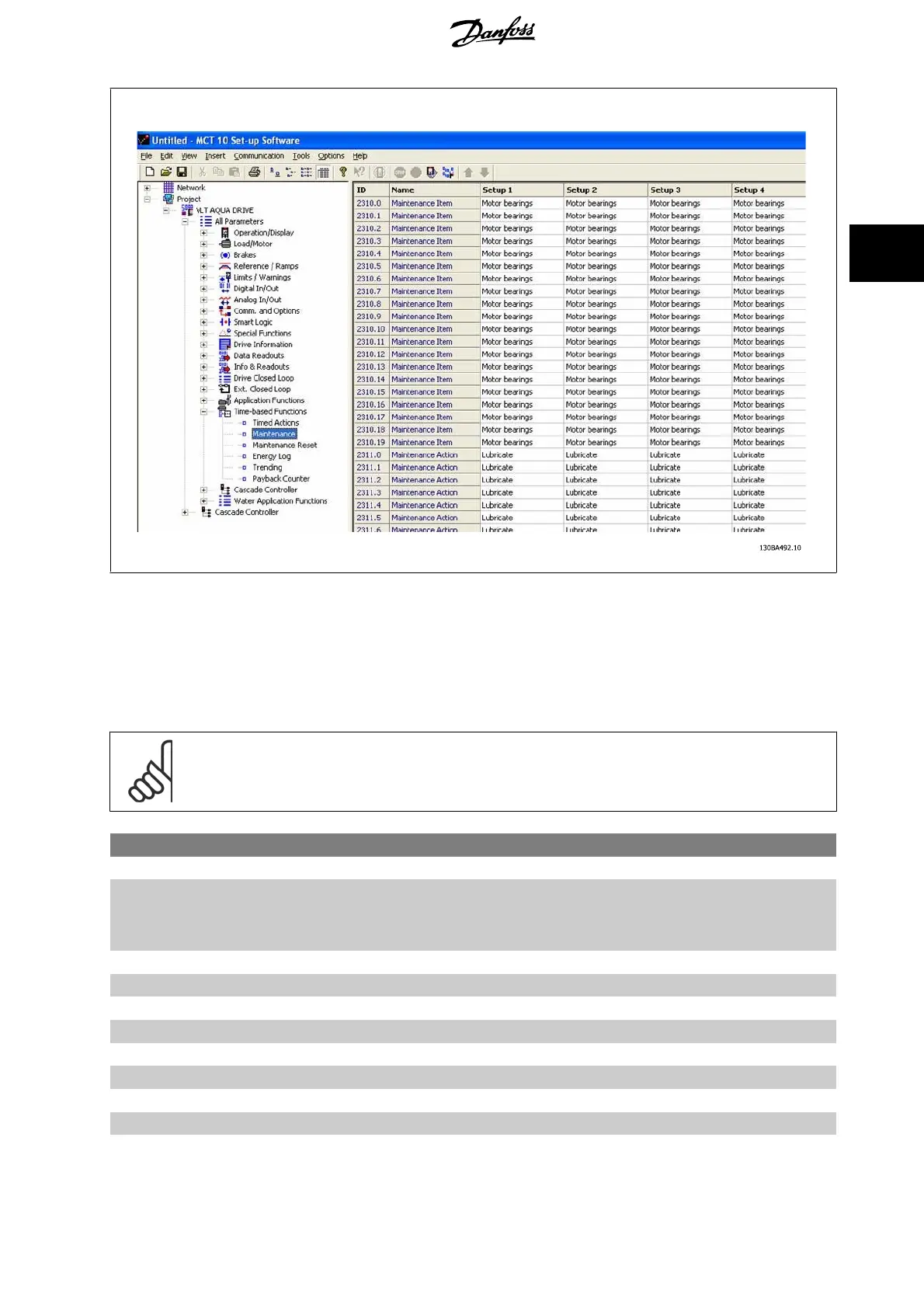

The Preventive Maintenance Events are defined in a 20 element array. Hence each Preventive Maintenance Event must use the same

array element index in par. 23-10

Maintenance Item

to par. 23-14

Maintenance Date and Time

.

23-10 Maintenance Item

Option: Function:

Array with 20 elements displayed below parameter number in the display. Press [OK] and step

between elements by means of and buttons on the LCP.

Select the item to be associated with the Preventive Maintenance Event.

[1] * Motor bearings

[2] Fan bearings

[3] Pump bearings

[4] Valve

[5] Pressure transmitter

[6] Flow transmitter

[7] Temperature transm.

[8] Pump seals

[9] Fan belt

VLT

®

HVAC Drive Programming Guide 3 Parameter Description

MG.11.C9.02 - VLT

®

is a registered Danfoss trademark

221

3

Loading...

Loading...