3-56 Ramp 2 S-ramp Ratio at Accel. End

Range: Function:

50 %* [Application dependant] Enter the proportion of the total ramp-up time (par. 3-51

Ramp 2 Ramp up Time

) in which the

acceleration torque decreases. The larger the percentage value, the greater the jerk compensation

achieved, and thus the lower the torque jerks in the application.

3-57 Ramp 2 S-ramp Ratio at Decel. Start

Range: Function:

50 %* [Application dependant] Enter the proportion of the total ramp-down time (par. 3-52

Ramp 2 Ramp down Time

) where the

deceleration torque increases The larger the percentage value, the greater the jerk compensation

achieved, and thus the lower the torque jerks in the application.

3-58 Ramp 2 S-ramp Ratio at Decel. End

Range: Function:

50 %* [Application dependant] Enter the proportion of the total ramp-down time (par. 3-52

Ramp 2 Ramp down Time

) where the

deceleration torque decreases. The larger the percentage value, the greater the jerk compensation

achieved, and thus the lower the torque jerks in the application.

3.5.5 3-8* Other Ramps

Configure parameters for special ramps e.g. Jog or Quick Stop.

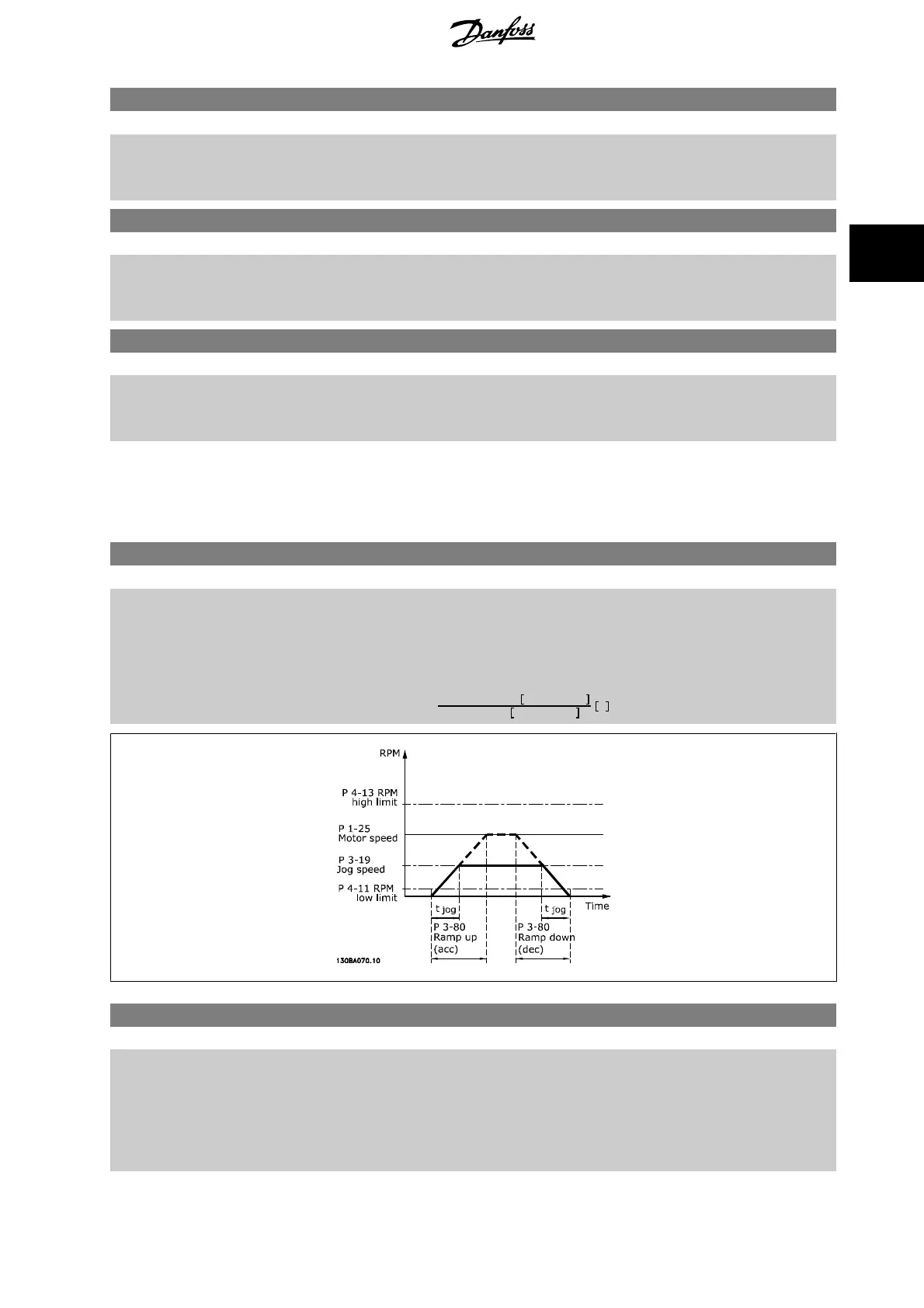

3-80 Jog Ramp Time

Range: Function:

Application

dependent*

[1.00 - 3600.00 s] Enter the jog ramp time, i.e. the acceleration/deceleration time between 0 RPM and the rated motor

speed (n

M,N

) (set in par. 1-25

Motor Nominal Speed

). Ensure that the resultant output current re-

quired for the given jog ramp time does not exceed the current limit in par. 4-18

Current Limit

. The

jog ramp time starts upon activation of a jog signal via the control panel, a selected digital input,

or the serial communication port.

par

. 3 − 80 =

tjog

×

nnorm

par

. 1 − 25

jog

speed

par

. 3 − 19

s

3-81 Quick Stop Ramp Time

Range: Function:

Application

dependent*

[0.01 - 3600.00 s] Enter the quick–stop ramp-down time, i.e. the deceleration time from the synchronous motor speed

to 0 RPM. Ensure that no resultant over-voltage will arise in the inverter due to regenerative oper-

ation of the motor required to achieve the given ramp-down time. Ensure also that the generated

current required to achieve the given ramp-down time does not exceed the current limit (set in

par. 4-18

Current Limit

). Quick-stop is activated by means of a signal on a selected digital input, or

via the serial communication port.

VLT

®

HVAC Drive Programming Guide 3 Parameter Description

MG.11.C9.02 - VLT

®

is a registered Danfoss trademark

69

3

Loading...

Loading...