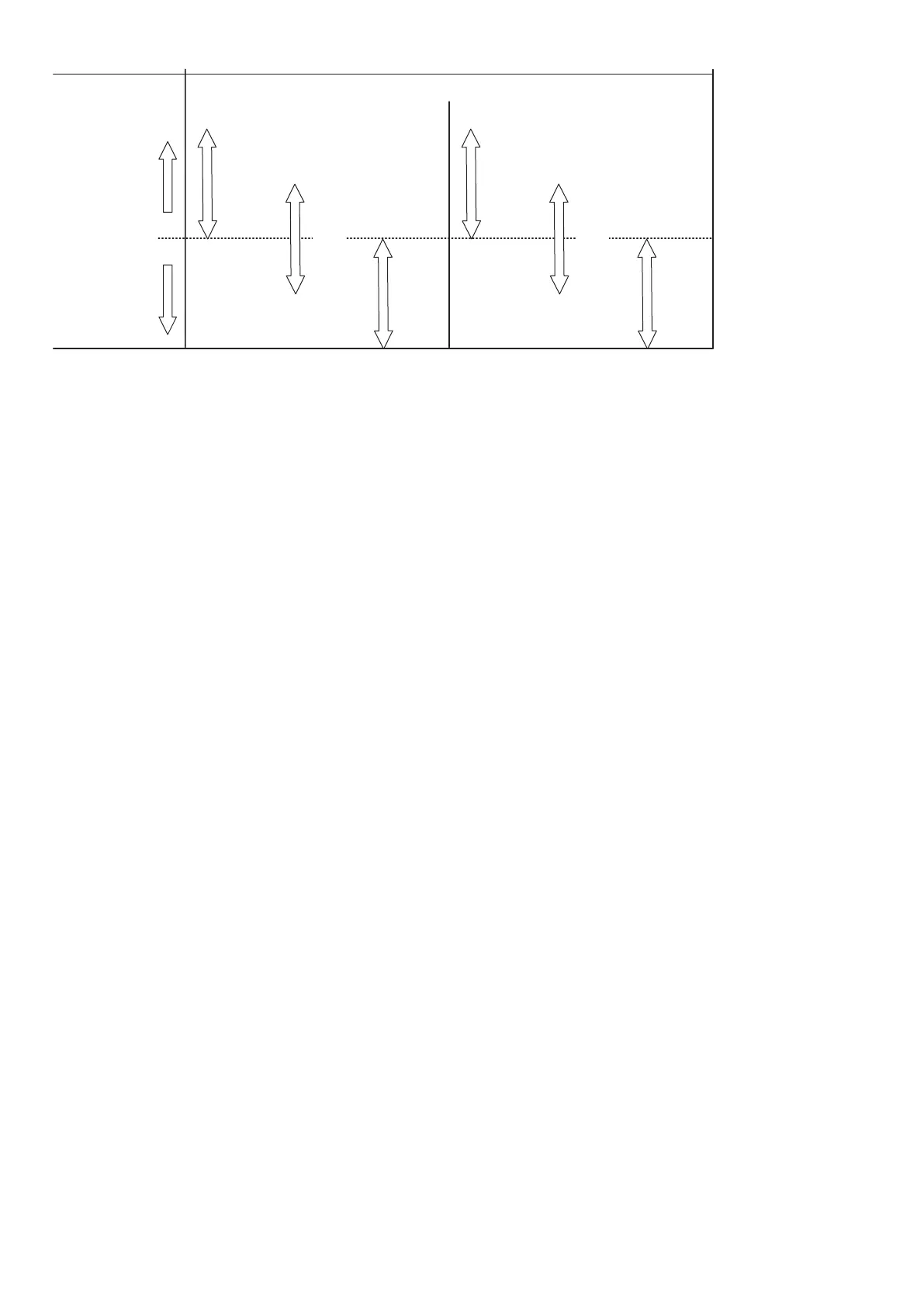

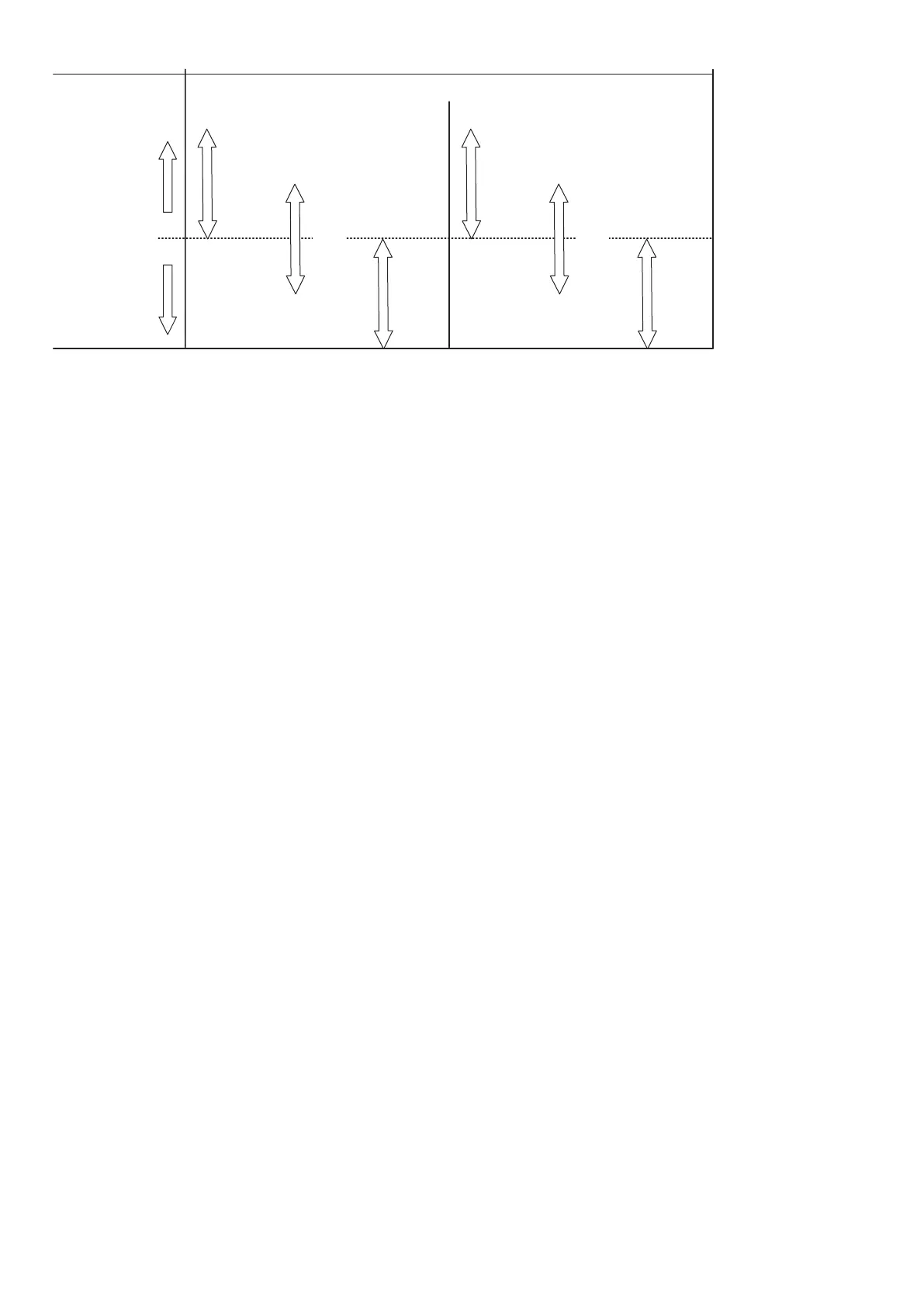

Set point

Below set point

Above set point

Direct Inverse

Analogue offset 100 % 50 % 0 %

Output

Input

100 % 50 % 0 %

0 %

50 %

100 %

0 %

50 %

100 %

0 %

50 %

100 %

100 %

50 %

0 %

100 %

50 %

0 %

100 %

50 %

0 %

100 % offset is commonly used with inverse output, like in the previous cooling example. For an example of other use, see “Example

of inverse output with 0 % offset”.

9: M-Logic min event set point

Determines the output of M-Logic function "PID1 force min. Outp."

10: M-Logic max event set point

Determines the output of M-Logic function "PID1 force max. Outp."

11: Relay Db

Deadband setting for relay control.

12: Relay Kp

Proportional gain value for relay control.

13: Relay Td

Derivative output for relay control.

14: Relay min on-time

Minimum output time for relay control. Set this to the minimum time that is able to activate the controlled actuator.

15: Relay period time

Total time for a relay activation period. When the regulation output is above this period time, the relay output is constantly activated.

17: Relay increase

Choose the terminal for the relay used for positive activation.

18: Relay decrease

Choose the terminal for the relay used for negative activation.

7.4 Kp gain compensation

7.4.1 Introduction

This document describes the functionality regarding the “Kp gain compensation”, so it is possible to utilise the function parameters

and help with setting up the function. This function is intended to be used when the AGC is controlling the cooling water system for

the genset.

As it is today, there are two situations in which the engine is in danger of ending in an oscillation that could shut down the engine:

1. Load impacts

2. Cold start of engine

In both situations, it is desired to have a higher gain when the change is needed, but a lower gain when the system has to stabilise.

Without "Kp gain compensation", the PID settings need to be balanced between reaction and stability. The “Kp gain compensation”

DESIGNER'S HANDBOOK 4189341275A EN Page 189 of 196

Loading...

Loading...